Parapet wall crown rigid waterproof system

A rigid waterproof, daughter technology, applied in the direction of roof insulation materials, etc., can solve problems such as hidden dangers of water leakage, and achieve the effect of extending service life, easy maintenance, and clean appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

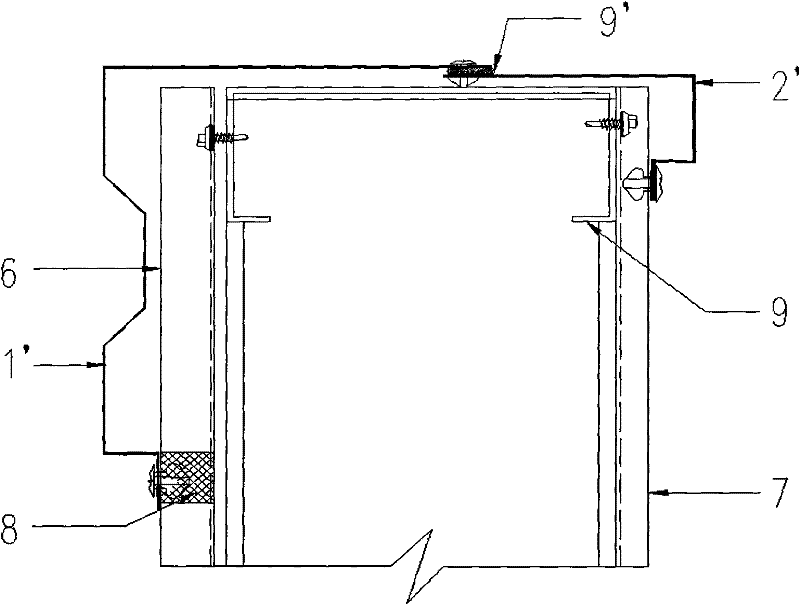

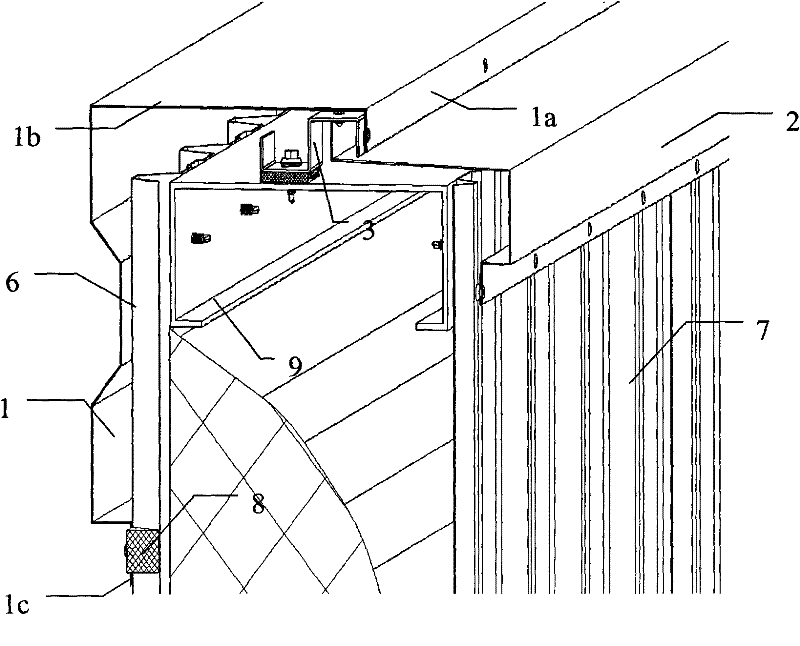

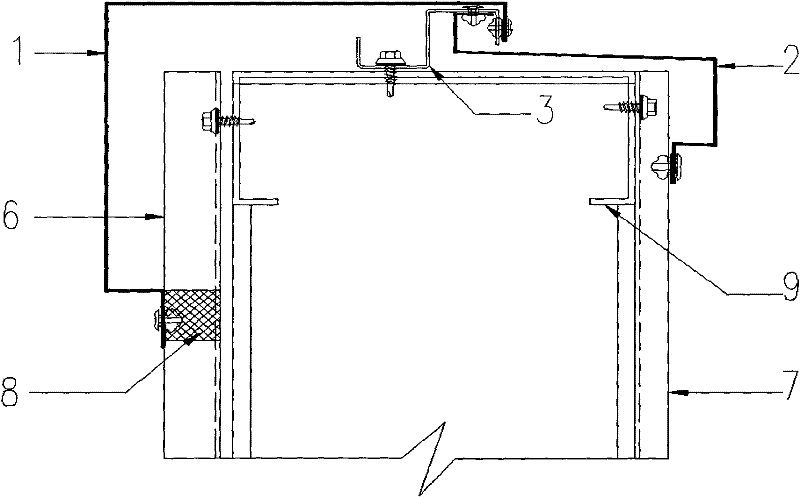

[0020] A rigid waterproof system for the top of a parapet wall, including an outer flashing part 1 of a parapet top, an inner flashing part 2 of a parapet top, a support conversion part 3, an outer wall profiled plate 6, an inner wall profiled plate 7, and a foam plug Head 8, parapet top purlin 9, such as image 3 As shown, the outer side of the parapet roof flashing member 1 is straight and consists of a folded edge 1a, an upper end surface 1b, and a lower folded edge 1c. The inner flashing part on the top of the parapet is composed of the upper end surface 2a, the lower flange 2b, the middle slope 2c, and the upper facade 2d. The inclination angle of the middle part 2c is 2° and the length is 115mm, which is conducive to the drainage of the inner flashing part to the roof ; The supporting conversion piece is composed of the lower end face 3a, the upper end face 3b, the right side face 3c, and the elevation face 3d. It adopts standard stamping parts and arranges them along th...

Embodiment 2

[0026] A rigid waterproof system for the top of a parapet wall on a metal wall, including an outer flashing part 1 of a parapet top, an inner flashing part 2 of a parapet top, a support conversion part 3, a rock wool sandwich panel 6a, and an inner wall profiled panel 7 , Parapet C-shaped steel purlin 9.

[0027] Figure 6 As shown, the outside of the outer flashing part 1 of the parapet top is in the shape of a garden arc, consisting of a folded edge 1a, an upper end face 1b, and a lower folded edge 1c. The inner flashing part 2 of the parapet top is composed of an upper end face 2a, a lower folded edge 2b, the middle inclined surface 2c, and the upper facade 2d. The inclination angle of the middle part 2c is 4° and the length is 135mm, which is beneficial for the drainage of the inner flashing part 2 to the roof; the supporting conversion part 3 consists of the lower end surface 3a, the upper end surface 3b, The right side 3c and the facade 3d are composed of standard stamp...

Embodiment 3

[0034] A rigid waterproof system for the top of a parapet wall on a metal wall, including an outer flashing part 1, an inner flashing part 2, a support conversion part 3, an outer wall profiled plate 6, an inner wall profiled plate 7, and a foam plug Head 8, parapet combined angle steel purlin 9a, such as Figure 7 As shown, the outside of the outer flashing part 1 of the parapet top is herringbone-shaped, consisting of a folded edge 1a, an upper end face 1b, and a lower folded edge 1c, and the inner flashing part of the parapet top is composed of an upper end face 2a, a lower folded edge 2b , the middle inclined plane 2c, and the upper façade 2d, the inclination angle of the middle part 2c is 5°, and the length is 230mm. The supporting conversion parts are arranged along the purlins of the parapet wall at an interval of 500mm. The installation method is as follows:

[0035] Step 1. After the steel structure parapet combined angle steel purlin 9a is installed, fix the outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com