Phenolic resin adhesive automatic detection equipment

An automatic detection, phenolic resin technology, applied in the directions of flow characteristics, measuring devices, material inspection products, etc., can solve the problems of cumbersome operation and poor test results, and achieve the effect of obvious test results and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

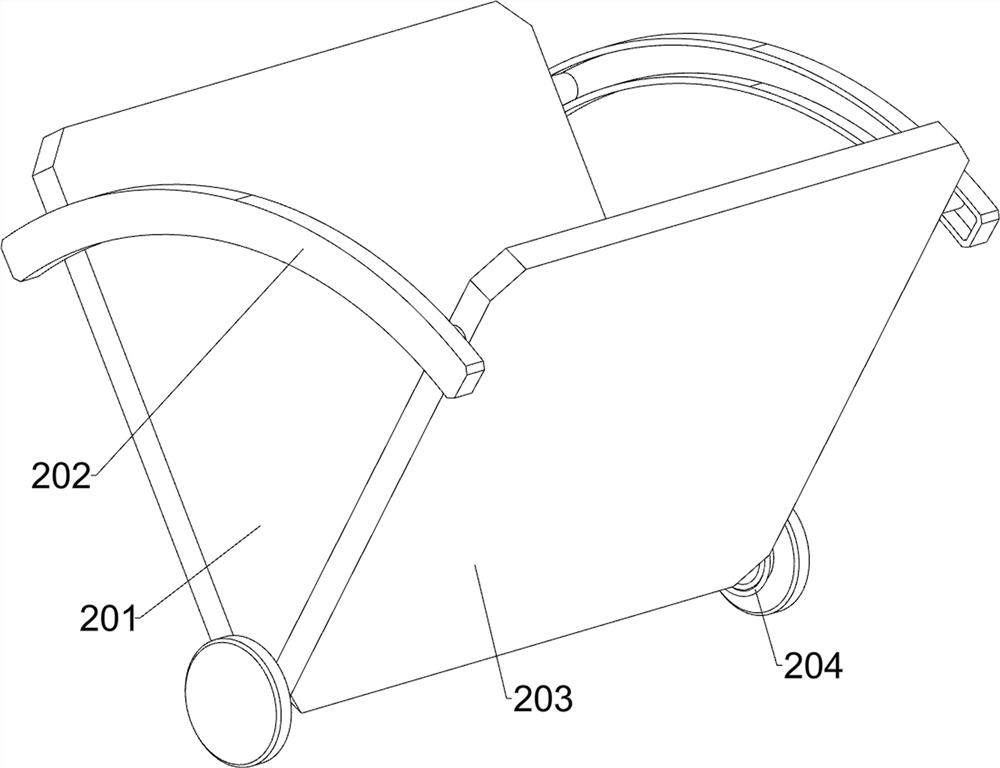

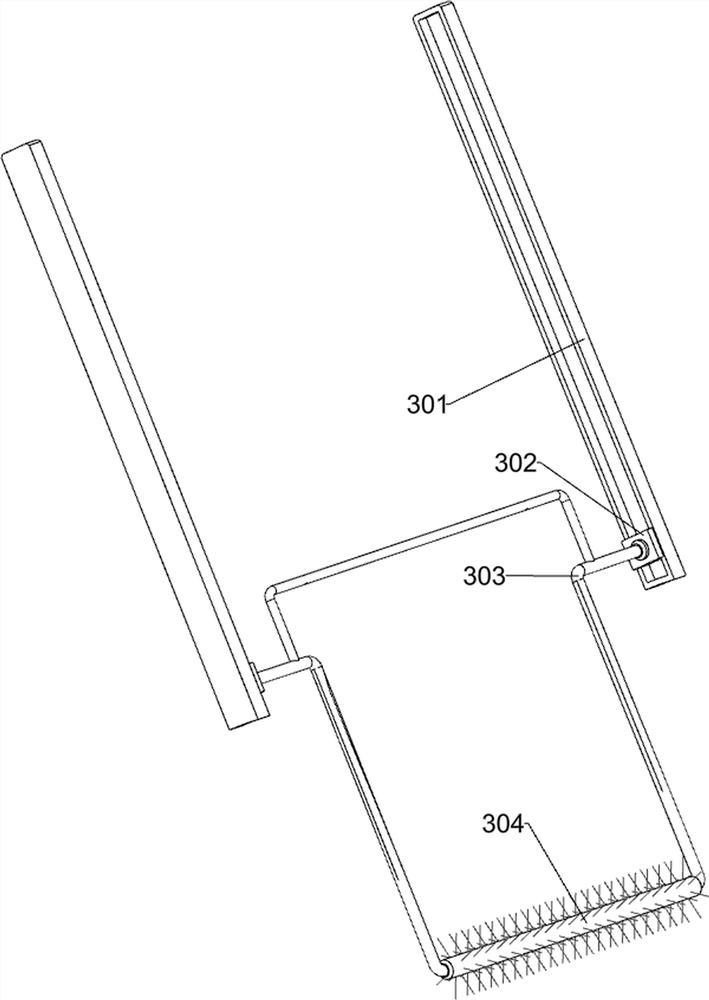

[0024] A kind of phenolic resin adhesive automatic detection equipment, such as Figure 1-4 As shown, it includes a support assembly 1, a test assembly 2 and a brush assembly 3, the support assembly 1 is provided with the test assembly 2, and the test assembly 2 is provided with the brush assembly 3.

[0025] When it is necessary to detect the bonding effect of the phenolic resin adhesive, the brushing component 3 is first stained with the phenolic resin adhesive, and then the phenolic resin adhesive is brushed on the test component 2 through the brush component 3, and the phenolic resin adhesive is tested by the test component 2. The bonding effect is tested.

[0026] The support assembly 1 includes a straight base 101, a connecting plate 102, a horizontal plate 103 and an inclined base 104. The middle parts of the straight bases 101 on the left and right sides are connected with the connecting plate 102, and the straight bases 101 are connected with a horizontal plate 103, a...

Embodiment 2

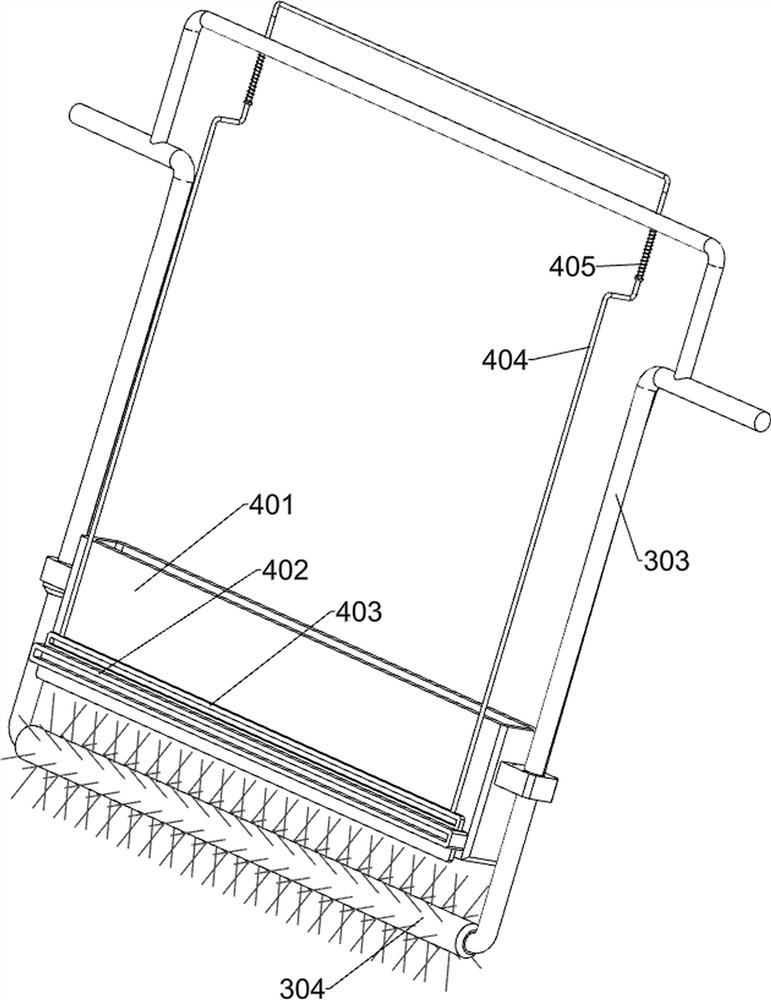

[0033] On the basis of Example 1, such as figure 1 , Figure 5 and Figure 6 As shown, it also includes a blanking assembly 4. The blanking assembly 4 includes a material storage frame 401, a guide block 402, a baffle plate 403, a pull rod 404, and a common spring 405. The bottom of the connecting rod 303 is connected with a material storage frame 401, and the material storage Frame 401 bottom rear side is provided with guide block 402, has groove on guide block 402, is provided with baffle plate 403 slidingly on guide block 402, has groove on baffle plate 403, and connecting rod 303 top sliding type is provided with pull bar 404, The pull rod 404 is connected to the baffle plate 403 , and common springs 405 are connected between the left and right sides of the pull rod 404 and the connecting rod 303 .

[0034] When it is necessary to test the bonding effect of the phenolic resin adhesive, the phenolic resin adhesive can be placed in the material storage frame 401, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com