Base tri element colour sublimed fastness balancing type dispersion gray dye mixture

A dye mixture, sublimation fastness technology, used in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of inconsistent sublimation, color and light changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one: a kind of gray disperse dye mixture

[0030] 1. Formula

[0031] Composition Sublimation fastness Content

[0032] Disperse Yellow (1) Level 3 19%;

[0033] Disperse Red (1) Grade 3 34%;

[0034] Disperse Blue 2BLN dye (C.I. Disperse Blue 56) Grade 3 36%;

[0035] Auxiliary balance.

[0036] 2. Preparation

[0037] The wet filter cake of the above dye and the auxiliary agent are sanded together according to the above ratio to process the finished product of the dye mixture.

[0038] 3. The formula of the above-mentioned disperse yellow (1)

[0039] Composition Content

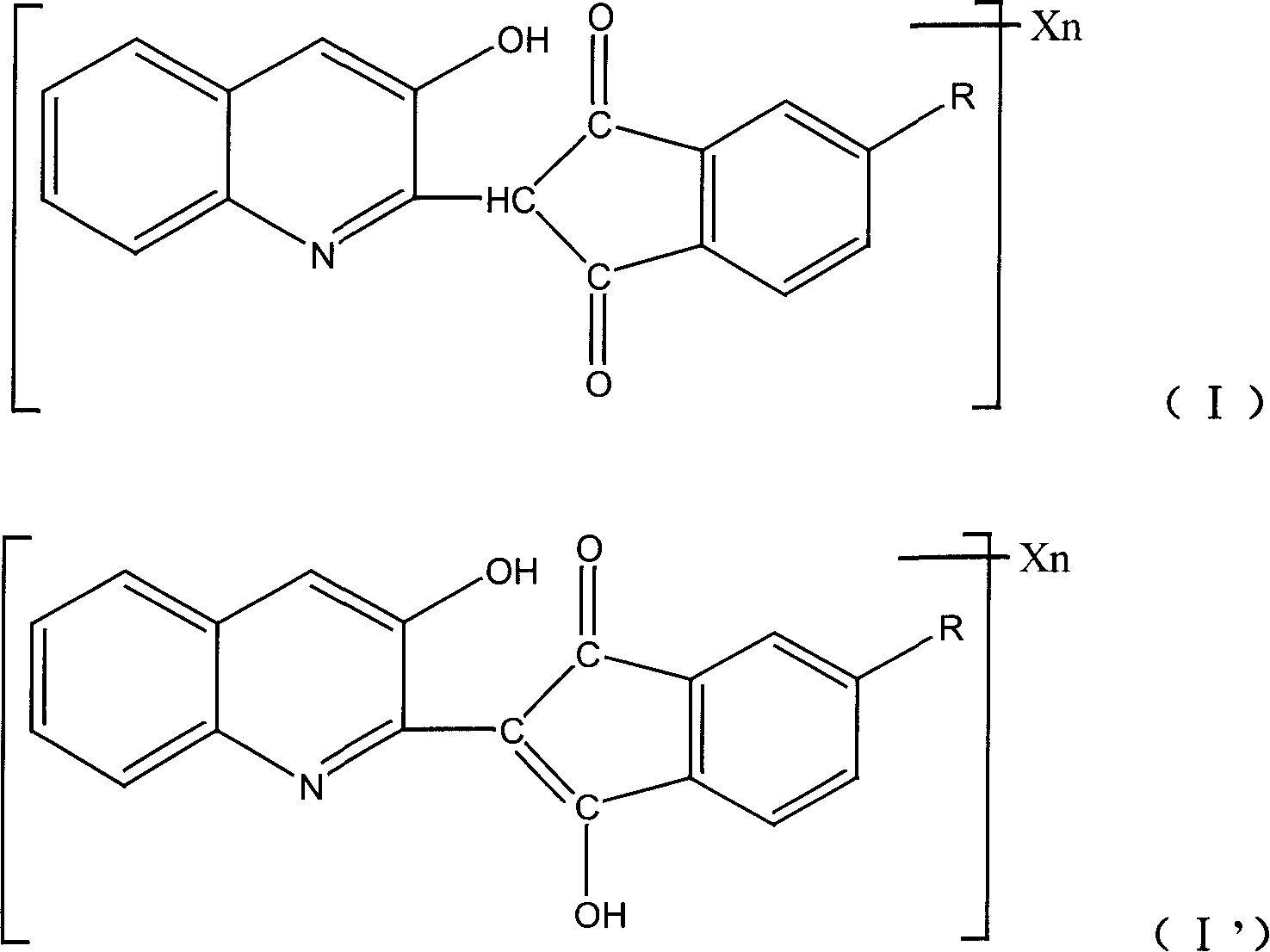

[0040] Meet the C.I. disperse yellow 54 dyes of general chemical formula (I) 17%;

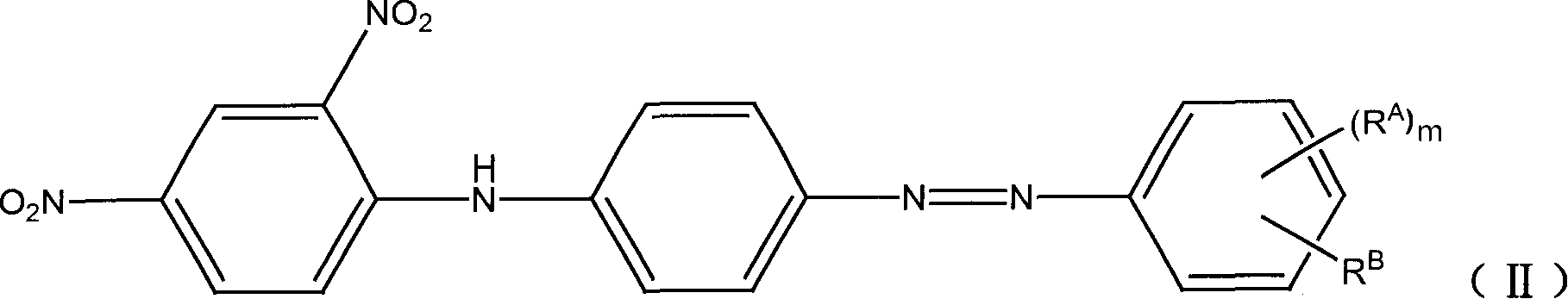

[0041] According to the disperse yellow Y dye of general chemical formula (II), see structural formula (V) 60%;

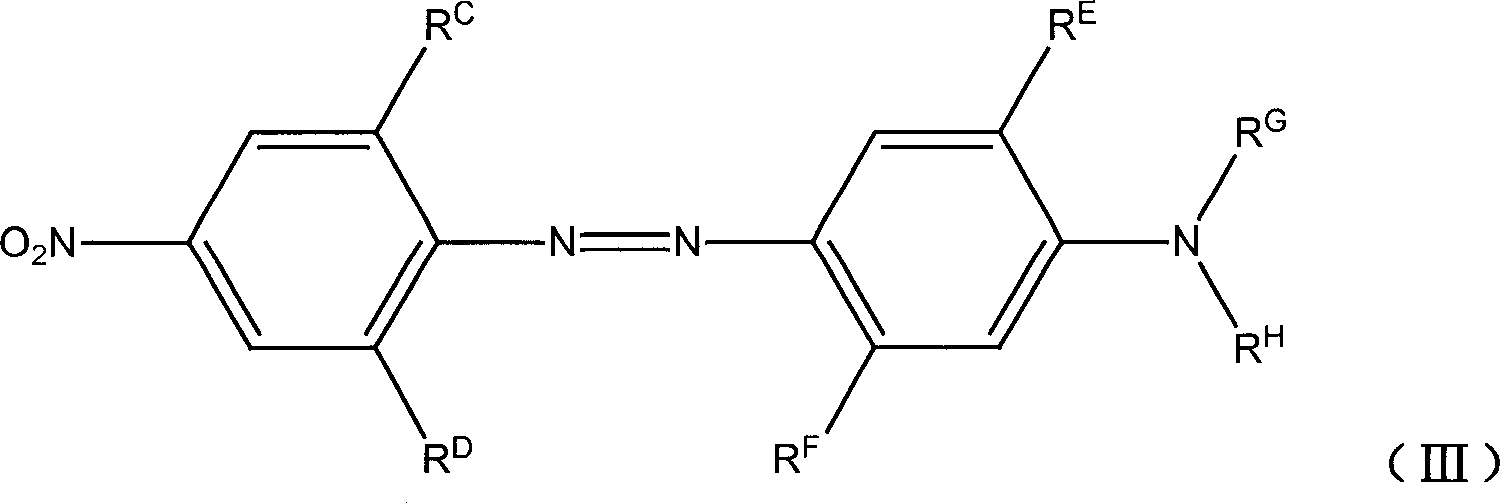

[0042] Meet the C.I. Disperse Orange 25 dyestuff of general chemical formula (III) 6%;

[0043] Auxiliary balance.

[0044] The structural formula (V) of Disperse Yellow Y is as foll...

Embodiment 2

[0051] Embodiment two: a kind of gray disperse dye mixture

[0052] 1. Formula

[0053] Composition Sublimation fastness Content

[0054] Disperse Yellow (2) Level 3 18%;

[0055] Disperse Red (2) Level 3 10%;

[0056] Disperse Blue 2BLN dye (C.I. Disperse Blue 56) Grade 3 35%;

[0057]Auxiliary balance.

[0058] 2, the preparation is the same as in Example 1.

[0059] 3. The formula of the above-mentioned disperse yellow (2)

[0060] Composition Content

[0061] Meet the C.I. disperse yellow 64 dyes of general chemical formula (I) 25%;

[0062] According to the disperse yellow Y dye of general chemical formula (II), see structural formula (V) 60%;

[0063] Meet the C.I. Disperse Orange 25 dyestuff of general chemical formula (III) 6%;

[0064] Auxiliary balance.

[0065] 4. The formula of above-mentioned disperse red (2)

[0066] Composition Content

[0067] Meet the C.I. disperse red 60 dyestuff of general chemical formula (IV) 50%;

[0068] C.I. Disperse Red 92...

Embodiment 3

[0070] Embodiment three: a kind of gray disperse dye mixture

[0071] 1. Formula

[0072] Composition Sublimation fastness Content

[0073] Disperse Yellow (3) Level 3 20%;

[0074] Disperse Red (3) Level 3 9%;

[0075] Disperse Blue 2BLN dye (C.I. Disperse Blue 56) Grade 3 40%;

[0076] Auxiliary balance.

[0077] 2, the preparation is the same as in Example 1.

[0078] 3. The formula of the above-mentioned disperse yellow (3)

[0079] Composition Content

[0080] Meet the C.I. disperse yellow 54 dyes of general chemical formula (I) 20%;

[0081] Meet the disperse yellow Y dye of general chemical formula (II), see structural formula (V) 45%;

[0082] Meet the C.I. Disperse Orange 25 dyestuff of general chemical formula (III) 6%;

[0083] Meet the C.I. disperse orange 41 dyestuff of general chemical formula (III) 20%;

[0084] Auxiliary balance.

[0085] 4. The formula of above-mentioned disperse red (3)

[0086] Composition Content

[0087] Meet the C.I. disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com