A kind of disperse dye composition, its preparation method and application

A technology of disperse dyes and compositions, applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems of dyeing compatibility and application performance that cannot fully meet the needs, and achieve high practical value, high fastness to sublimation, and comprehensive The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

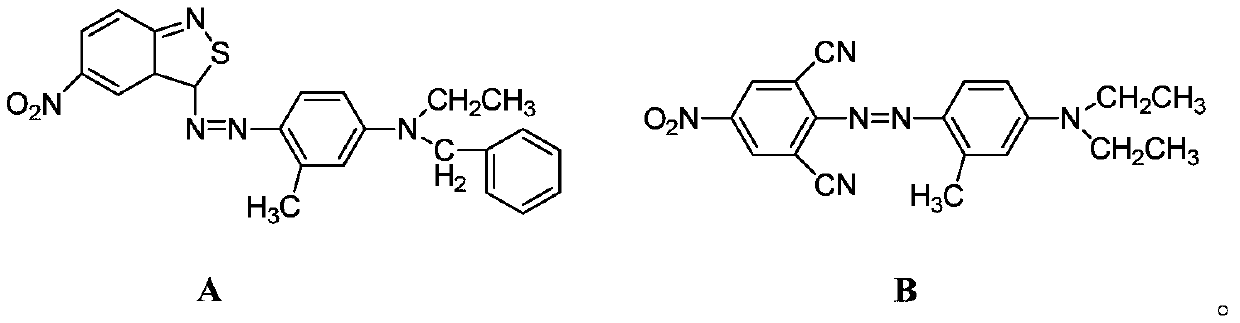

Method used

Image

Examples

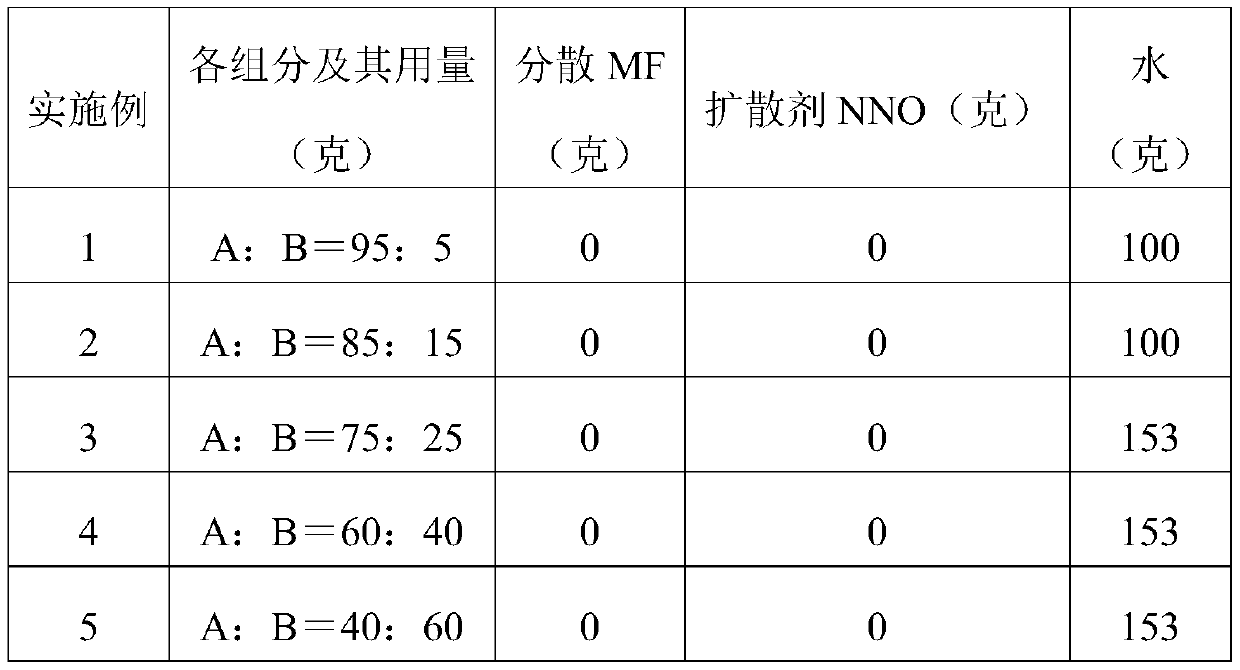

Embodiment 1-20

[0034] Wherein, the preparation method of the disperse dye composition described in embodiment 1-8 and comparative example 1-2 is preferably any in the following methods:

[0035] Method 1: After mixing all the components with water according to the mass percentage, carry out protonation treatment, and spray dry;

[0036] Method 2: After mixing each component with water, carry out protonization treatment, spray drying, and then mix according to mass percentage.

[0037] Wherein, the preparation method of the disperse dye composition described in embodiment 9-20 and comparative example 3-6 is preferably any in the following methods:

[0038] Method A: After mixing all components with additives and water according to the mass percentage, carry out protonation treatment and spray drying;

[0039] Method B: After mixing each component with additives and water, carry out protonation treatment, spray dry, and then mix according to mass percentage.

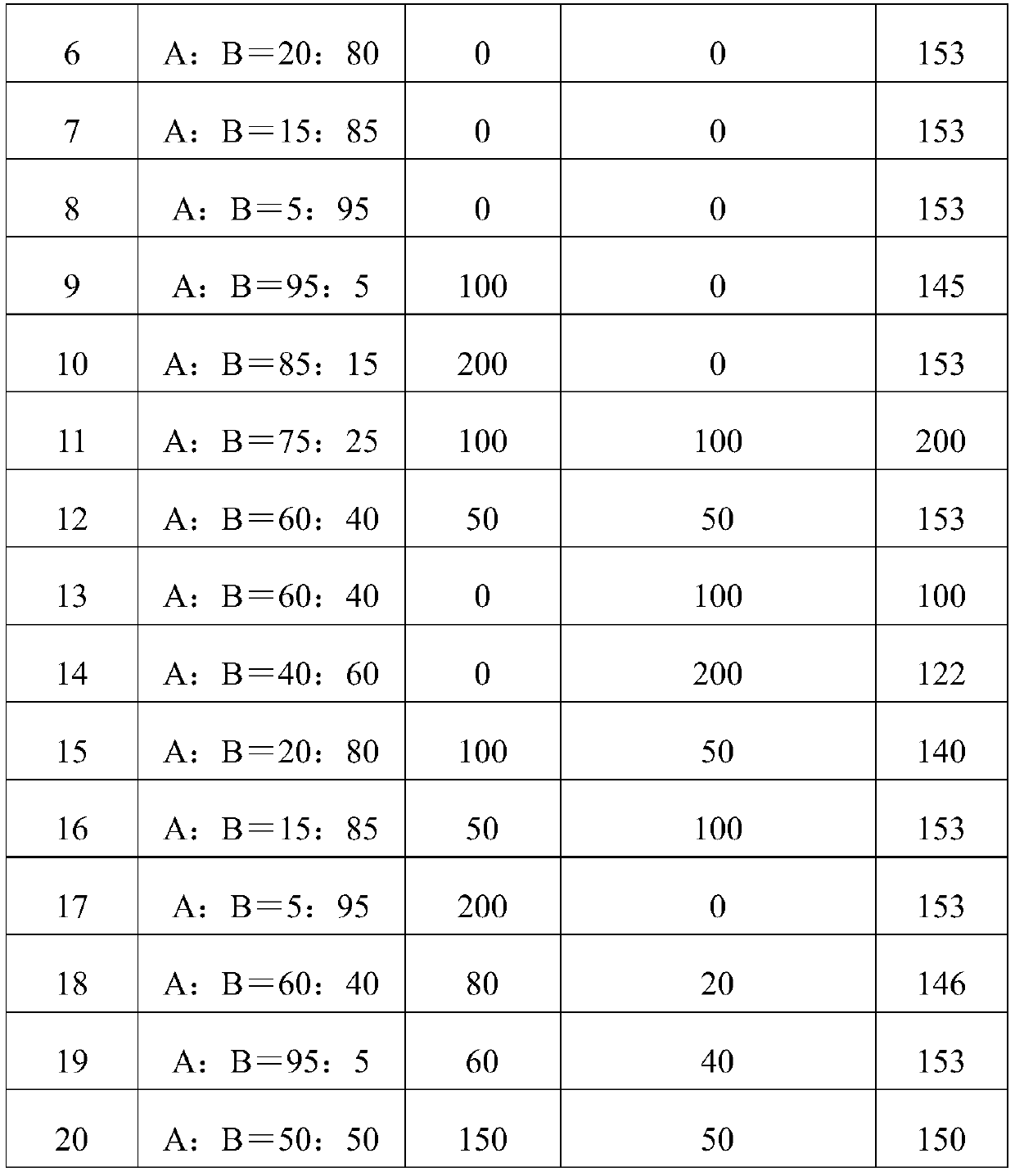

[0040] Table 1

[0041]

[...

Embodiment 12

[0055] Example 12 and Comparative Example 3 are shown in Table 4 below for alkali-resistant shades.

[0056] Each get X gram (X refers to the quality under the same color light intensity with contrast sample) the disperse dye composition that embodiment 12 and comparative example 3 make, be dispersed in 500 milliliters of water, mix with 60 milliliters of water after imbibing 20 milliliters. Use acetic acid to adjust the pH of the dyeing bath to 4, heat up to 70°C and put 2 grams of polyester cloth into it for dyeing, heat up to 130°C in 30 minutes, keep warm for 30 minutes, cool to 90°C to test the dyed cloth sample.

[0057] Using AATCC 6-2001, test the acid and alkali resistance of the above cloth samples. The test results are as follows:

[0058] Table 4

[0059]

[0060]

[0061] 3. Color fastness to peroxide bleaching

[0062] Each get X gram (X refers to the quality under the same color light intensity with contrast sample) embodiment 12 and the disperse dye comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com