Isoptericola salitolerans and application of isoptericola salitolerans in production of seaweed liquid fertilizer

A technology of seaweed liquid and termites, applied in the field of functional fermentation strain screening, can solve the problems of inability to release active ingredients, poor salt tolerance, unsatisfactory degradation effect of macromolecular polysaccharides, etc., and achieve the effect of promoting plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

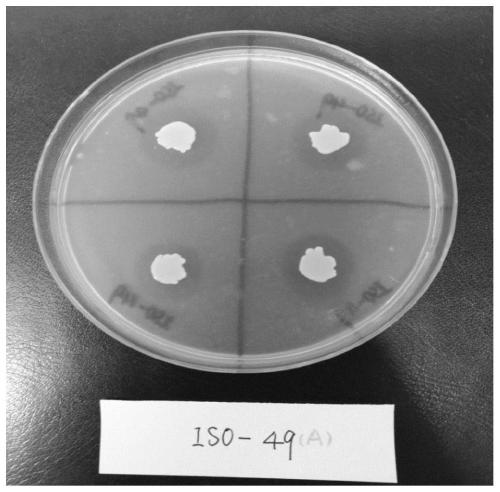

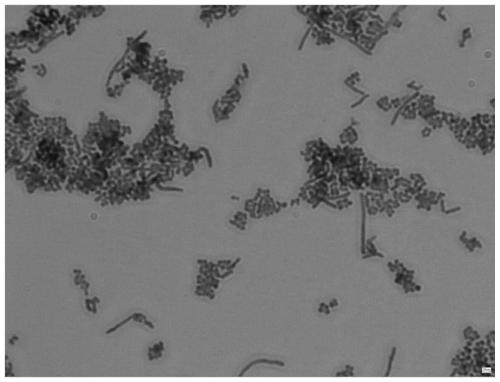

[0041] Example 1: Screening and Identification of Salt-tolerant Termites ISO-49

[0042] Step 1: Collect Samples

[0043]Seawater, sediment and kelp samples were collected from 9 different kelp cultivation areas in Rongcheng. The seawater samples were directly separated by the dilution coating method. Sea mud and kelp samples need to be diluted and shaken before being separated by dilution coating method.

[0044] The specific operation is as follows:

[0045] Take 10 grams of sea mud and 10 grams of kelp samples (cut into small pieces with sterile scissors in advance), add them to 90 mL of sterile normal saline, shake at room temperature for 2 hours at 150 r / min to make a sample solution.

[0046] Take 0.1mL of the sample solution and spread it directly on the 2216E medium (Difco, product number: 212185), place it upside down at 30°C and culture it for 5 days, pick the single colonies grown on the plate, and perform streak purification on the 2216E medium plate . A total...

Embodiment 2

[0064] Example 2: Ability to produce alginate lyase from the salt-tolerant termite fungus ISO-49

[0065] The method for measuring the activity of alginate lyase is as follows:

[0066] The activity of alginate lyase was detected by 3,5-dinitrosalicylic acid (DNS) colorimetric method. The increasing amount of reducing sugar in the reaction solution is used as the detection index of enzyme activity, and the increasing amount of reducing sugar is determined by DNS reagent. Glucose was used as a standard to make a standard curve, and the amount of reducing sugar generated was calculated according to the difference in absorbance between the reaction group and the control group. One unit of enzyme activity is defined as the amount of enzyme required for the reaction solution to produce 1 μg of reducing sugar per minute under the above conditions.

[0067] Take 0.1 mL of centrifuged fermentation supernatant (crude enzyme liquid), mix with 0.9 mL of 0.3% sodium alginate solution (d...

Embodiment 3

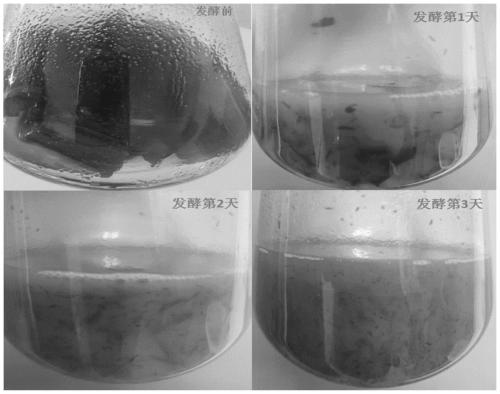

[0076] Example 3: Detection of the ability of fucoidan in fermented kelp by the salt-tolerant termite fungus ISO-49

[0077] Step 1: Crush the dried kelp to a 60-mesh sieve and store at 4°C.

[0078] Step 2: inoculate the strain ISO-49 in the re-screened liquid seed medium, culture at a temperature of 30° C., place on a shaker and culture at a speed of 150 r / min for 24 hours, and prepare the fermentation broth of the strain ISO-49.

[0079] Step 3: Weigh 100g of kelp powder, 10g of sodium alginate, 5g of potassium dihydrogen phosphate, and 5g of magnesium sulfate, then add 800mL of water, stir evenly, adjust the pH to 6.0, and sterilize at 121°C for 20 minutes.

[0080] Step 4: Add 100mL of ISO-49 fermentation broth, and ferment at 30°C for 6 days to make kelp liquid fertilizer.

[0081] In the control group, 100 ml of sterile liquid seed medium was used instead of adding bacterial solution.

[0082] Step 5: Determining the content of fucoidan in the kelp solution after ferm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com