Technology for preparing surface-coated modified Ag/ZnO nano composite antibacterial agent

A nano-composite, surface-coated technology, applied in the field of antibacterial materials, can solve the problems of weak photocatalytic ability, application limitations, and ZnO photocatalytic antibacterial ability cannot be reflected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

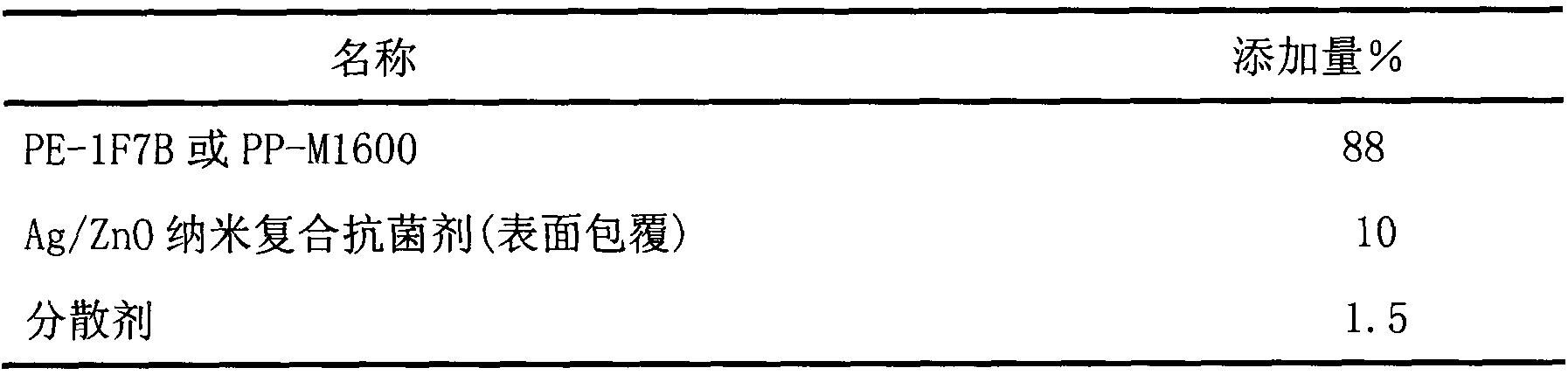

[0026] A process for preparing a surface-coated and modified Ag / ZnO nano composite antibacterial agent includes the following steps:

[0027] 1) Add dispersant sodium hexametaphosphate to distilled water, the mass ratio of distilled water to dispersant is 500:1, stir until completely dissolved;

[0028] 2). Add nano-ZnO powder to the solution of step 1), the mass ratio of distilled water and nano-ZnO powder is 60:1, then first use ultrasonic dispersion for 30 minutes, then add AgNO 3 , Nano ZnO powder and AgNO 3 The mass ratio of the solution is 20:1, adjust the pH value of the solution to 7, and mechanically stir in a water bath at 25℃ for 1h;

[0029] 3) Wash, filter, and then dry in a constant temperature drying oven at 80°C for 3 hours;

[0030] 4) Put it into a box-type resistance furnace and bake at 600℃ for 2h;

[0031] 5) Take out the original powder of Ag / ZnO nanocomposite antibacterial agent, add the original Ag / ZnO antibacterial agent powder in distilled water, and then add s...

Embodiment 2

[0033] A process for preparing a surface-coated and modified Ag / ZnO nano composite antibacterial agent, comprising the following steps:

[0034] 1) Add dispersant sodium hexametaphosphate to distilled water, the mass ratio of distilled water and dispersant is 500:1, stir until completely dissolved;

[0035] 2). Add nano-ZnO powder to the solution of step 1), the mass ratio of distilled water and nano-ZnO powder is 60:1, then first use ultrasonic dispersion for 30 minutes, then add AgNO 3 , Nano ZnO powder and AgNO 3 The mass ratio of the solution is 20:1, adjust the pH value of the solution to 8, and mechanically stir for 2h in a 40℃ water bath;

[0036] 3) Wash, filter, and then dry in a constant temperature drying oven at 120°C for 4 hours;

[0037] 4) Put it into a box-type resistance furnace and roast at 800℃ for 4h;

[0038] 5) Take out the original powder of Ag / ZnO nanocomposite antibacterial agent, add the original Ag / ZnO antibacterial agent powder in distilled water, and then ad...

Embodiment 3

[0040] A process for preparing a surface-coated and modified Ag / ZnO nano composite antibacterial agent includes the following steps:

[0041] 1) Add dispersant sodium hexametaphosphate to distilled water, the mass ratio of distilled water and dispersant is 500:1, stir until completely dissolved;

[0042] 2). Add nano-ZnO powder to the solution of step 1), the mass ratio of distilled water and nano-ZnO powder is 60:1, then first use ultrasonic dispersion for 30 minutes, then add AgNO 3 , Nano ZnO powder and AgNO 3 The mass ratio is 20:1, adjust the pH value of the solution to 7.5, and mechanically stir for 1.5h in a 35℃ water bath;

[0043] 3) Wash, filter, and then dry in a constant temperature drying oven at 100°C for 3.5h;

[0044] 4) Put it into a box-type resistance furnace and bake it at 700℃ for 3h;

[0045] 5) Take out the original powder of Ag / ZnO nanocomposite antibacterial agent, add the original Ag / ZnO antibacterial agent powder in distilled water, and then add sodium laurate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com