High-temperature-resistant coating and preparation method thereof

A high-temperature-resistant coating and inorganic filler technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of unclear cadmium red color loss mechanism, coating brittleness, post-processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

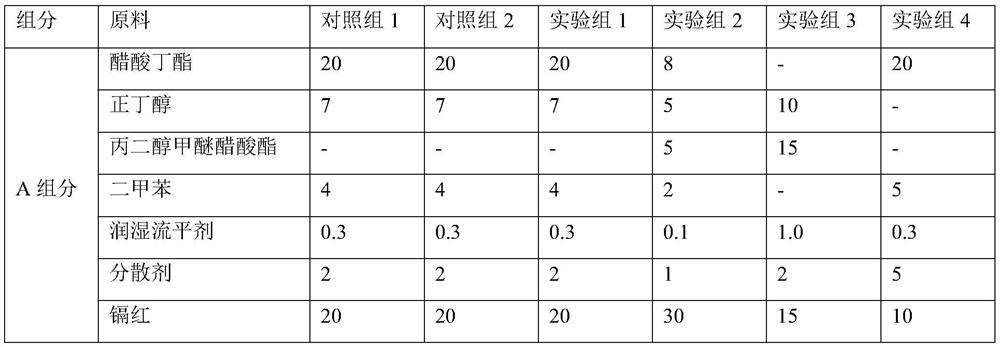

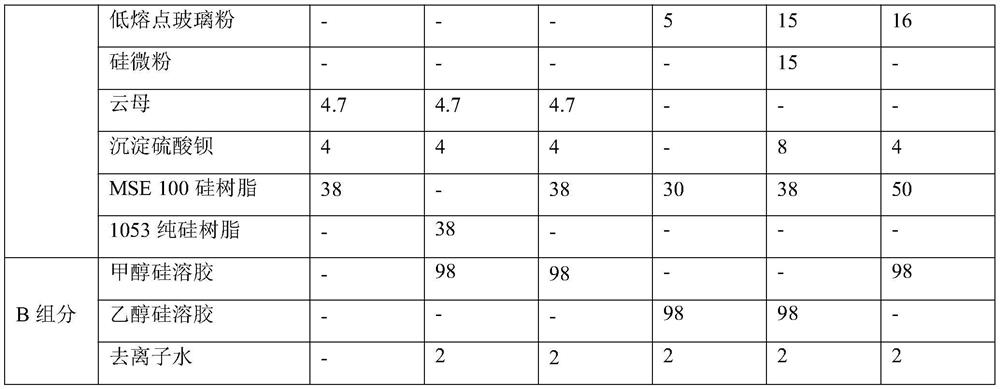

[0033] (1) Preparation of components of high temperature resistant coatings:

[0034] Preparation of component A: According to the ratio shown in the following table 1, first mix and stir the solvent, pigment and filler, dispersant and wetting and leveling agent, then add MSE 100 silicone resin or 1053 pure silicone resin, Grind in a disperser until the particle size is ≤25 microns, filter and pack.

[0035] Component B: Take industrial-grade products as raw materials, add 2% deionized water according to the mass ratio, stir evenly, filter and pack.

[0036] Formulation of control group and experimental group in table 1

[0037]

[0038]

[0039] (2) coating preparation;

[0040] Mix components A and B according to a certain ratio, stir evenly and filter with a 100-mesh filter for spraying. The base material is a stainless steel base material polished with 240 mesh sandpaper and soot blown.

[0041] Control group 1:

[0042] Spray component A directly on the polishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com