Novel environmentally-friendly high-speed gravure printing compound ink

An environmentally friendly, high-speed technology, applied in ink, household utensils, applications, etc., can solve the problems of easy yellowing, poor light resistance and chemical resistance, and achieve excellent light stability and chemical resistance, no shrinkage cavity, Effect of improved printing suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

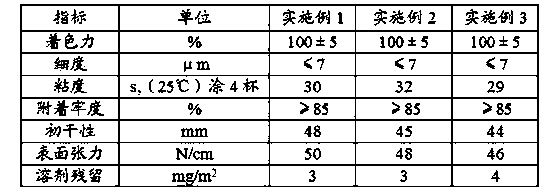

Embodiment 1

[0017] In the present embodiment, the novel environment-friendly high-speed interior printing composite ink of the present invention is composed of the following components by mass: 30 parts of polyurethane resin, 12 parts of polyethylene vinyl acetate, 35.7 parts of ester alcohol solvent, 0.8 parts of propylene glycol methyl ether acetate 10 parts of pigment, 0.5 part of polyester polyamide copolymer (dispersant), 0.5 part of polyethylene wax powder, 1 part of modified chlorinated polypropylene (adhesion promoter), 1 part of antistatic agent, 6 parts of matting liquid 2 parts, 2 parts of matting powder and 0.5 parts of defoamer. Among them, the polyurethane resin is a polymer of isophorone diisocyanate and polypropylene-1,2-ethylene glycol ether; the ester alcohol solvent is composed of n-propyl ester, isopropanol, ethyl ester and n-propanol according to the mass parts The ratio is 30:10:8:2; the antistatic agent is composed of 48% quaternary ammonium salt cationic surfactant...

Embodiment 2

[0025] In the present embodiment, the novel environment-friendly high-speed interior printing composite ink of the present invention is composed of the following components by mass: 35 parts of polyurethane resin, 15 parts of polyethylene vinyl acetate, 40 parts of ester alcohol solvent, 1 part of propylene glycol methyl ether acetate 12 parts of pigment, 0.6 parts of polyester polyamide copolymer (dispersant), 0.6 parts of polyethylene wax powder, 1.5 parts of modified chlorinated polypropylene (adhesion promoter), 1.2 parts of antistatic agent, 6.5 parts of matting liquid 2.2 parts, 2.2 parts of matting powder and 0.6 parts of defoamer. Among them, the polyurethane resin is a polymer of isophorone diisocyanate and polypropylene-1,2-ethylene glycol ether; the ester alcohol solvent is composed of n-propyl ester, isopropanol, ethyl ester and n-propanol according to the mass parts The ratio is 30:10:8:2; the antistatic agent is composed of 48% quaternary ammonium salt cationic s...

Embodiment 3

[0028] In this embodiment, the novel environment-friendly high-speed inner printing composite ink of the present invention is composed of the following components by mass: 30 parts of polyurethane resin, 12 parts of polyethylene vinyl acetate, 33 parts of ester alcohol solvent, 0.6 parts of propylene glycol methyl ether acetate 8 parts, 8 parts of pigment, 0.45 parts of polyester polyamide copolymer (dispersant), 0.45 parts of polyethylene wax powder, 0.9 parts of modified chlorinated polypropylene (adhesion promoter), 0.9 parts of antistatic agent, 5.5 parts of matting liquid 1.8 parts, 1.8 parts of matting powder and 0.45 parts of defoamer. Among them, the polyurethane resin is a polymer of isophorone diisocyanate and polypropylene-1,2-ethylene glycol ether; the ester alcohol solvent is composed of n-propyl ester, isopropanol, ethyl ester and n-propanol according to the mass parts The ratio is 30:10:8:2; the antistatic agent is composed of 50% quaternary ammonium salt cation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com