Water-based two-pack polyurethane preservative coating and preparation method thereof

A water-based two-component, anti-corrosion coating technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., to achieve the effect of good physical and mechanical properties, excellent weather resistance, and fast hardening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

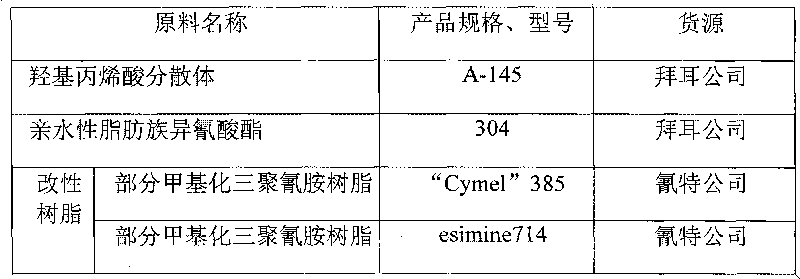

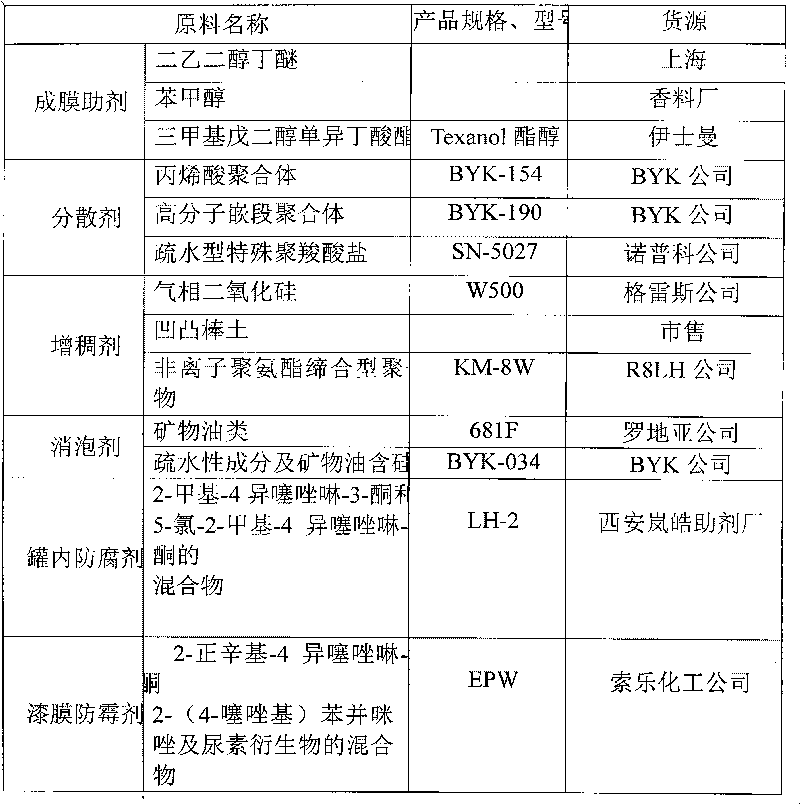

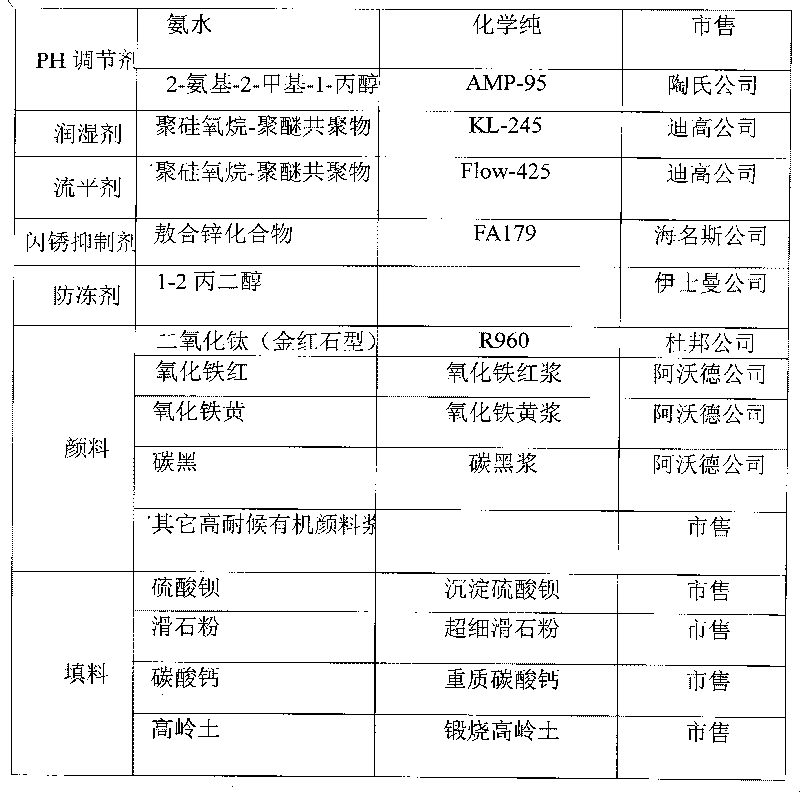

Method used

Image

Examples

Embodiment 1

[0032] A. Paint (Part A): Add 40.5g of water into the batching tank according to the raw material names and proportions listed in Table 3, and add 7.0g of dispersant, 3.0g of defoamer, and antiseptic in the tank under stirring. 0.5g, paint film antifungal agent 1.0g, flash rust inhibitor 2.0g, wetting agent 1.0g, leveling agent 1.0g, stir evenly, add 2.5g of pH regulator, adjust the pH value of the system to 8.0~9.0 , add imported rutile titanium dioxide, stir and mix well, then pump the material into the grinder for grinding, when the slurry fineness is ≤50μm, add 690.0g of A-145 emulsion, 20.0g of modified resin, and stir slowly and uniformly Add 35.0g of film-forming aid, 3.0g of antifreeze, add 12.0g of thickener according to the viscosity requirements of the paint, filter with 80-100 mesh screen when the product quality index reaches the standard requirements, and obtain the paint (component A) after packaging ).

[0033] B. Add 203.0g of 304 curing agent into the batchi...

Embodiment 2-6

[0036] Adopt the same method as Example 1 to prepare water-based two-component polyurethane anticorrosion coating component A and component B, and the respective weighing and proportioning of the raw materials used in Examples 2-6 are shown in Table 3 and Table 4.

[0037] The aqueous self-emulsifying acrylate dispersion used in Examples 1-6 has a solid content of 45±2%, and a -OH percentage of about 3.3%.

[0038] table 5

[0039]

[0040]As can be seen from Table 4, the artificial accelerated aging index of the water-based two-component polyurethane anti-corrosion coating of the present invention reaches more than 1000h, surpassing the 800h artificial acceleration of the long-acting topcoat stipulated in the industry standard HG / T3656-1999 "Steel Structure Bridge" indicator requirements. The conventional performance index of paint film also meets the technical requirements of solvent-based polyurethane paint. The anticorrosion performance meets the general requirements....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com