Method for preparing 1-Methoxy-2-propyl acetate by continuous esterification reaction

A technology of propylene glycol methyl ether acetate and propylene glycol methyl ether, which is applied in the field of preparation of propylene glycol methyl ether acetate, can solve the problems of complex technological process, low production efficiency, a large amount of solid waste and waste water, etc., and achieves simple operation mode and high production efficiency. The effect of cost reduction and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

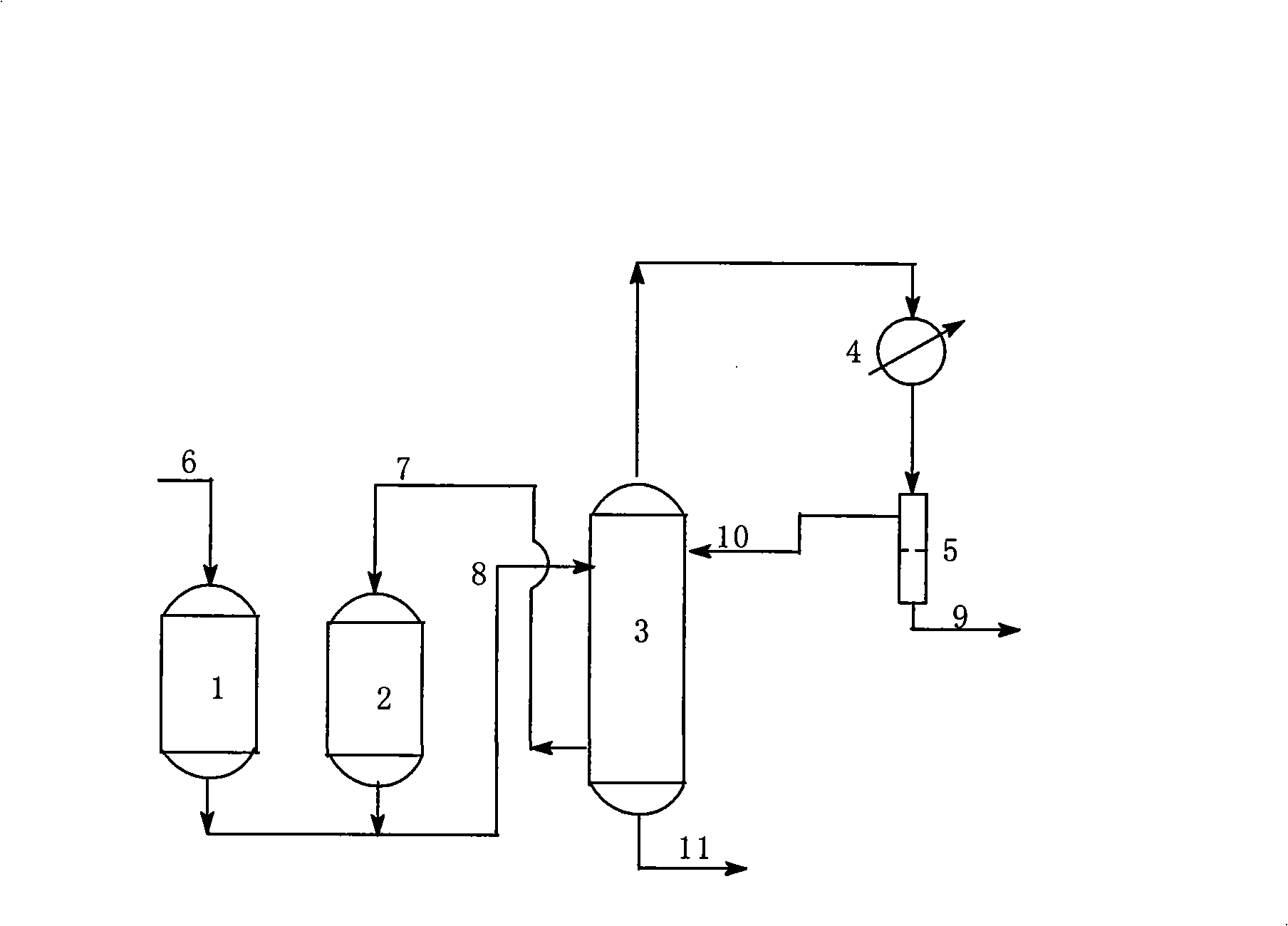

[0020] process such as figure 1 As shown, the raw materials propylene glycol methyl ether and acetic acid preheated to 110°C are fed into the first-stage fixed-bed reactor 1 equipped with 5L solid acid catalyst continuously at a molar ratio of 1:1 at a flow rate of 15L / h. The esterification reaction temperature 110℃, space velocity is 3h -1 . The material reacted in the first fixed-bed reactor 1 enters the distillation tower 3. In the distillation tower 3, the water generated by the esterification reaction forms an azeotrope at 68-71 °C in the presence of water-carrying agent benzene and is continuously absorbed separate. The dehydrated material is continuously drawn out with a flow rate of 30L / h in the stripping section of the distillation tower 3 and transported to the second stage fixed-bed reactor 2 equipped with a 5L solid acid catalyst to continue the esterification reaction. The reaction temperature is 120 ℃, space velocity is 6h -1. The material flow rate input to...

Embodiment 2

[0022] process such as figure 1 As shown, the raw materials propylene glycol methyl ether and acetic acid preheated to 90 °C are continuously input into the first-stage fixed-bed reactor 1 equipped with 5 L solid acid catalyst at a molar ratio of 1.5:1 at a flow rate of 10 L / h, and the esterification reaction The temperature is 90°C and the space velocity is 2h -1 . The materials reacted in the first fixed-bed reactor 1 enter the distillation tower 3, and in the distillation tower 3, the water generated by the esterification reaction forms an azeotrope at 69-71 °C in the presence of cyclohexane water-carrying agent and continuously was separated. The esterification reaction material from which moisture has been removed is continuously extracted at a flow rate of 10L / h in the stripping section of the distillation tower 3 and transported to the second-stage fixed-bed reactor 2 equipped with 5L solid acid catalyst, and the esterification reaction temperature is 90°C , airspeed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com