Method for producing propylene glycol methyl ether acetate

A technology of propylene glycol methyl ether acetate and propylene glycol methyl ether, which is applied in the field of producing propylene glycol methyl ether acetate, can solve the problems of low investment, achieve high reaction efficiency, increase catalyst concentration, and avoid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

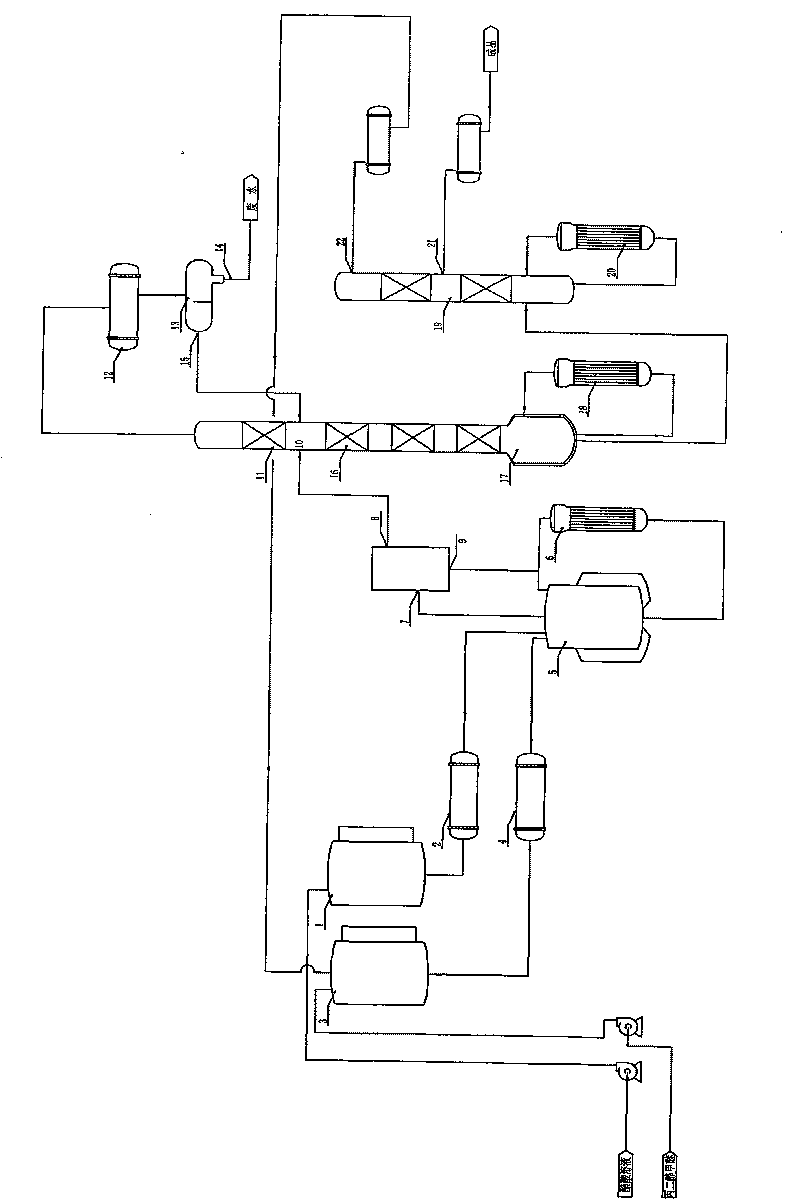

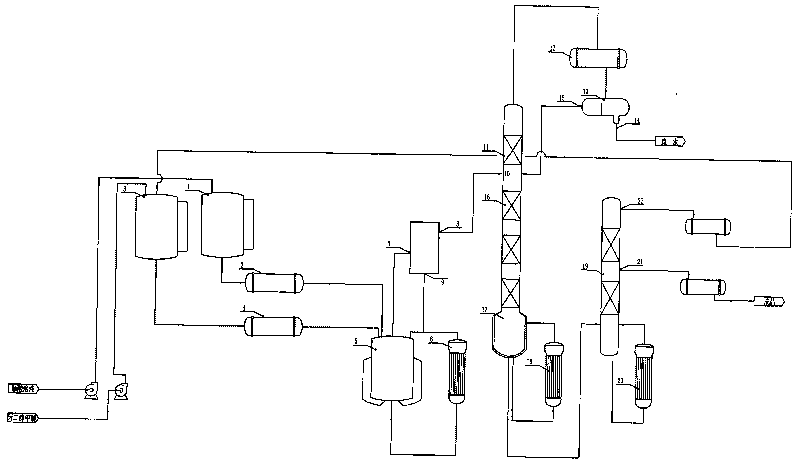

[0028] Step 1, pump 12000kg of glacial acetic acid into batching kettle 1, add 7.6kg (equivalent to 0.02% of the molar number of glacial acetic acid) monohydrate p-toluenesulfonic acid crystals, preheat to 95 ℃ by heat exchange in preheater 2 19,800kg (equivalent to 1.1 times the molar number of glacial acetic acid) mass fraction of 99.7% propylene glycol methyl ether is pumped into the batching kettle 3, and is preheated to 97° C. by heat exchange in the preheater 4;

[0029] Step 2: Reactor 5 and reboiler 6 are made of graphite-impregnated polytetrafluoroethylene, pump preheated propylene glycol methyl ether and acetic acid dissolved with p-toluenesulfonic acid into reactor 5, and heat to 113-115°C , so that the esterification reaction occurs, the water generated by the reaction enters the reactive distillation tower through the acid trap in the gas phase, and forms an azeotrope with the benzene added from the upper part of the tower, and the temperature at the top of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com