Urethane acrylate oligomer, preparation method of urethane acrylate oligomer, and coating prepared from urethane acrylate oligomer

A polyurethane acrylate and oligomer technology, applied in the field of coatings, can solve the problems of curing and inability to carry out ultraviolet light, achieve good stain resistance, hinder the penetration of oil stains, and improve the compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

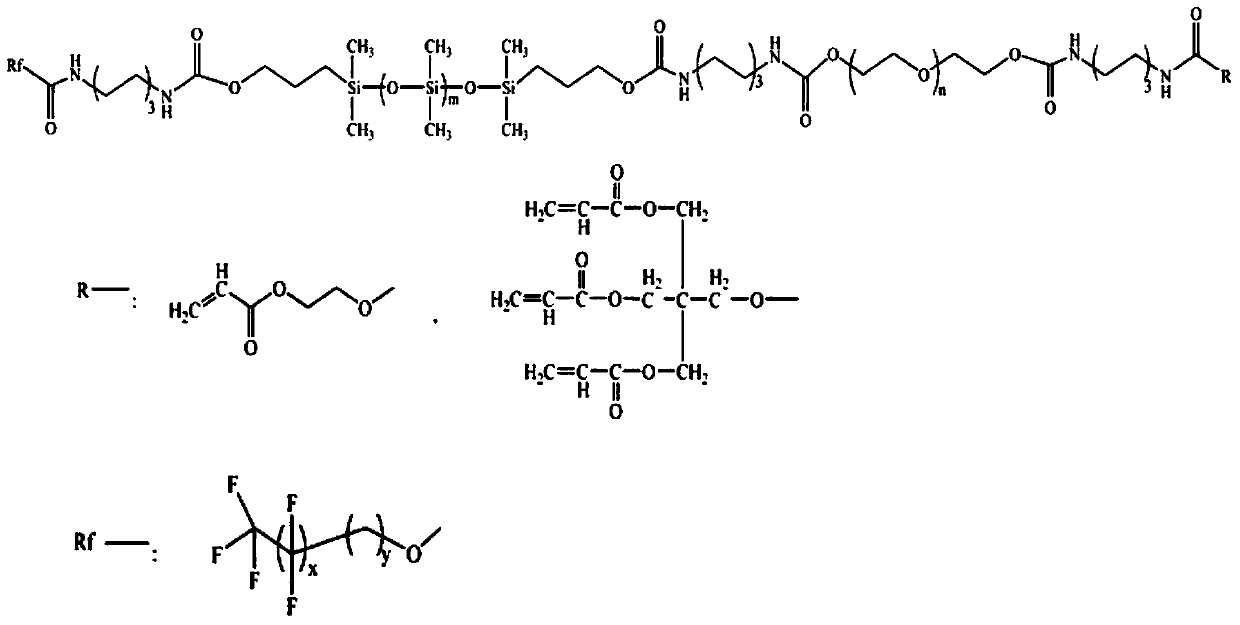

Image

Examples

Embodiment 1

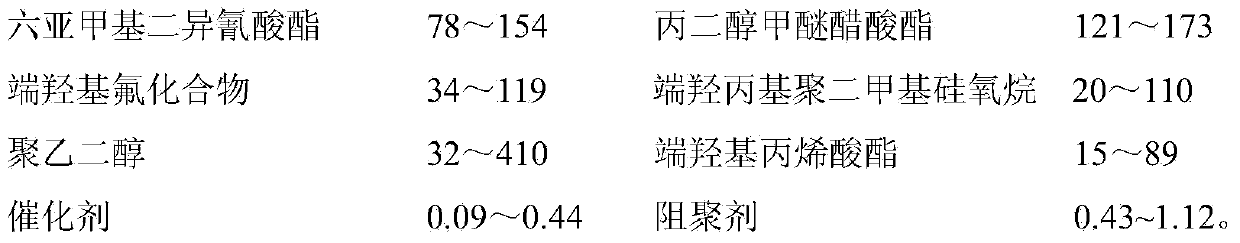

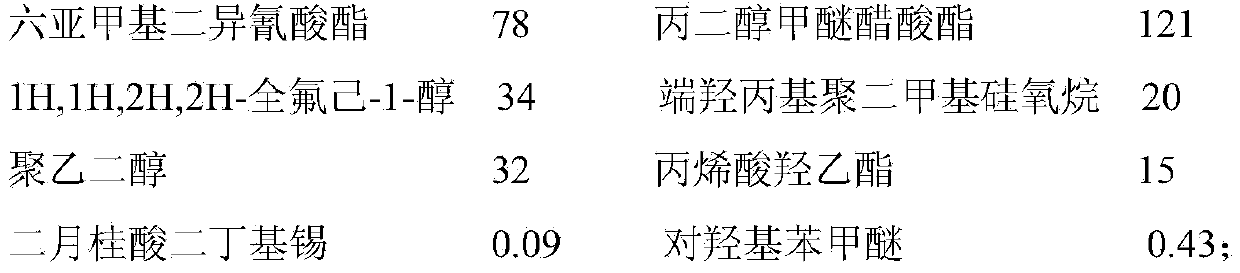

[0057] A kind of polyurethane acrylate oligomer, in parts by weight, the raw material comprises the following components:

[0058]

[0059] The molecular weight of the terminal hydroxypropyl polydimethylsiloxane is 400 Daltons;

[0060] The molecular weight of the polyethylene glycol is 400 Daltons.

[0061] The preparation method of above-mentioned polyurethane acrylate oligomer, comprises the following steps:

[0062] The first step: under the condition of nitrogen protection, the temperature is controlled at 65°C, and 78g of hexamethylene diisocyanate and 65g of propylene glycol methyl ether acetate are added to the three-necked flask, and 34g of 1H is added dropwise at a speed of 3ml / min. 1H, 2H, 2H-perfluorohexan-1-ol, after the dropwise addition, continue to stir and react for 1 hour to obtain the first intermediate;

[0063] The second step: under the condition of nitrogen protection, the temperature is controlled at 75°C, and 35g of propylene glycol methyl ether a...

Embodiment 2

[0078] A kind of polyurethane acrylate oligomer, in parts by weight, the raw material comprises the following components:

[0079]

[0080] The molecular weight of the terminal hydroxypropyl polydimethylsiloxane is 2000 Daltons;

[0081] The molecular weight of the polyethylene glycol is 1000 Daltons.

[0082] The preparation method of above-mentioned polyurethane acrylate oligomer, comprises the following steps:

[0083] The first step: under the condition of nitrogen protection, the temperature is controlled at 70°C, and 154g of hexamethylene diisocyanate and 85g of propylene glycol methyl ether acetate are added to the three-necked flask, and 119g of 1H is added dropwise at a rate of 5ml / min. 1H, 2H, 2H-perfluoro-1-decanol, after the dropwise addition, continue to stir and react for 2.5 hours to obtain the first intermediate;

[0084] The second step: under the condition of nitrogen protection, the temperature is controlled at 80°C, add 50g of propylene glycol methyl e...

Embodiment 3

[0099] A kind of polyurethane acrylate oligomer, in parts by weight, the raw material comprises the following components:

[0100]

[0101] The molecular weight of the terminal hydroxypropyl polydimethylsiloxane is 1000 Daltons;

[0102] The molecular weight of the polyethylene glycol is 600 Daltons.

[0103] The preparation method of above-mentioned polyurethane acrylate oligomer, comprises the following steps:

[0104] The first step: under the condition of nitrogen protection, the temperature is controlled at 68°C, 85g of hexamethylene diisocyanate and 70g of propylene glycol methyl ether acetate are added to the three-necked flask, and 58g of 1H is added dropwise at a speed of 4ml / min. 1H, 2H, 2H-tridecafluoro-1-octanol, after the dropwise addition, continue to stir and react for 2 hours to obtain the first intermediate;

[0105] The second step: under the condition of nitrogen protection, the temperature is controlled at 78°C, 40g of propylene glycol methyl ether ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com