Method for continuously synthesizing propylene glycol methyl ether acetate

A technology of propylene glycol methyl ether acetate and propylene glycol methyl ether, which is applied in the field of synthesis of propylene glycol methyl ether acetate, can solve problems such as complex process, low production efficiency, and environmental pollution, and achieve simple operation mode and high production efficiency , The effect of less discharge of waste water and waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

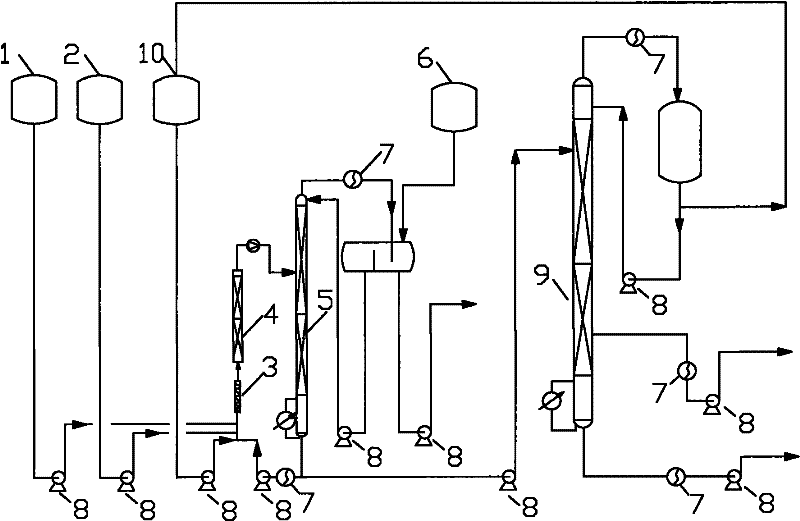

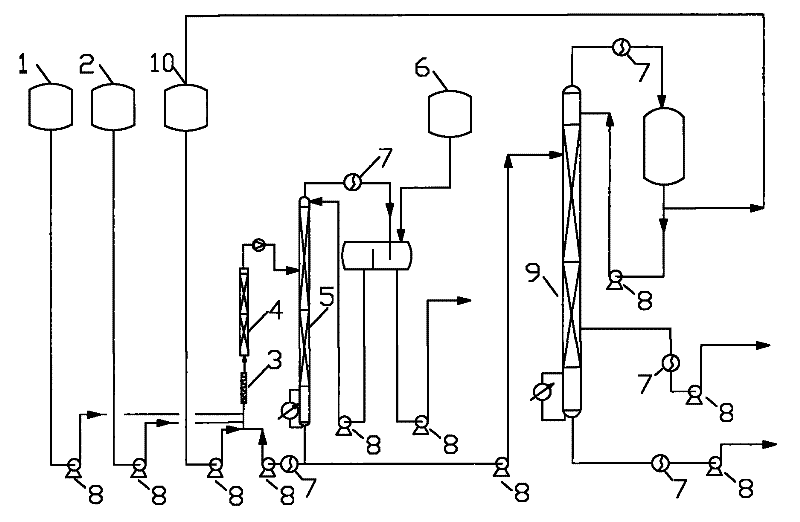

[0022] A kind of continuous synthetic method of propylene glycol methyl ether acetate, its difference is: it comprises the following steps: take propylene glycol methyl ether and glacial acetic acid as raw material, carry out esterification reaction in the fixed-bed reactor 4 of filling acidic resin catalyst The reaction product after the esterification enters the dehydration distillation tower 5 and the azeotropic dehydrating agent for azeotropic dehydration, and the dehydrated material is continuously extracted from the bottom of the dehydration distillation tower 5 and returned to the fixed bed reactor 4 to continue the esterification reaction. After the cycle is established, the feed of raw materials is stopped until the esterification reaction balance reaches the equilibrium conversion rate; when the esterification reaction balance is reached, the continuous production is started, and the fixed bed reactor 4 starts to feed continuously, and simultaneously from the tower of ...

Embodiment 1

[0033] The technological process of the continuous synthetic method of propylene glycol methyl ether acetate is as figure 1 As shown, in the fixed bed-dehydration distillation column continuous esterification reaction section: the propylene glycol methyl ether and acetic acid which are preheated to 100°C in the propylene glycol methyl ether tank 1 and the acetic acid tank 2 respectively, with a molar ratio of 1.8: 1, the total flow rate 60ml / h, after being mixed by the static mixer 3, it is continuously pumped into the fixed-bed reactor 4 equipped with 400ml of solid acid catalyst. The esterification reaction temperature in the fixed-bed reactor is 100°C, and the reaction pressure is 0.5MPa. The reaction product after the fixed-bed esterification reaction is continuously pumped in from the top of the dehydration distillation tower 5, and the azeotropic dehydrating agent cyclohexane stored in the cyclohexane tank 6 is fed from the top of the dehydration distillation tower 5, and...

Embodiment 2

[0036] The technological process of the continuous synthetic method of propylene glycol methyl ether acetate is as figure 1As shown, in the fixed bed-dehydration distillation column continuous esterification reaction section: the propylene glycol methyl ether and acetic acid which are preheated to 100°C in the propylene glycol methyl ether tank 1 and the acetic acid tank 2 respectively, with a molar ratio of 1.8: 1, the total flow rate 60ml / h, after being mixed by the static mixer 3, it is continuously pumped into the fixed-bed reactor 4 equipped with 400ml of solid acid catalyst. The esterification reaction temperature in the fixed-bed reactor is 85°C, and the reaction pressure is 1.0MPa. The reaction product after the fixed-bed esterification reaction is continuously pumped in from the top of the dehydration distillation tower 5, and the azeotropic dehydrating agent stored in the cycloethane tank 6 is fed from the top of the dehydration distillation tower 5 by sec-butyl aceta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com