Process for preparing polyurethane/acrylic hybrid dispersions

A technology of acrylic and polyurethane, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of limited application, PU prepolymer dispersed in water, PUA hybrid dispersion performance is difficult to control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

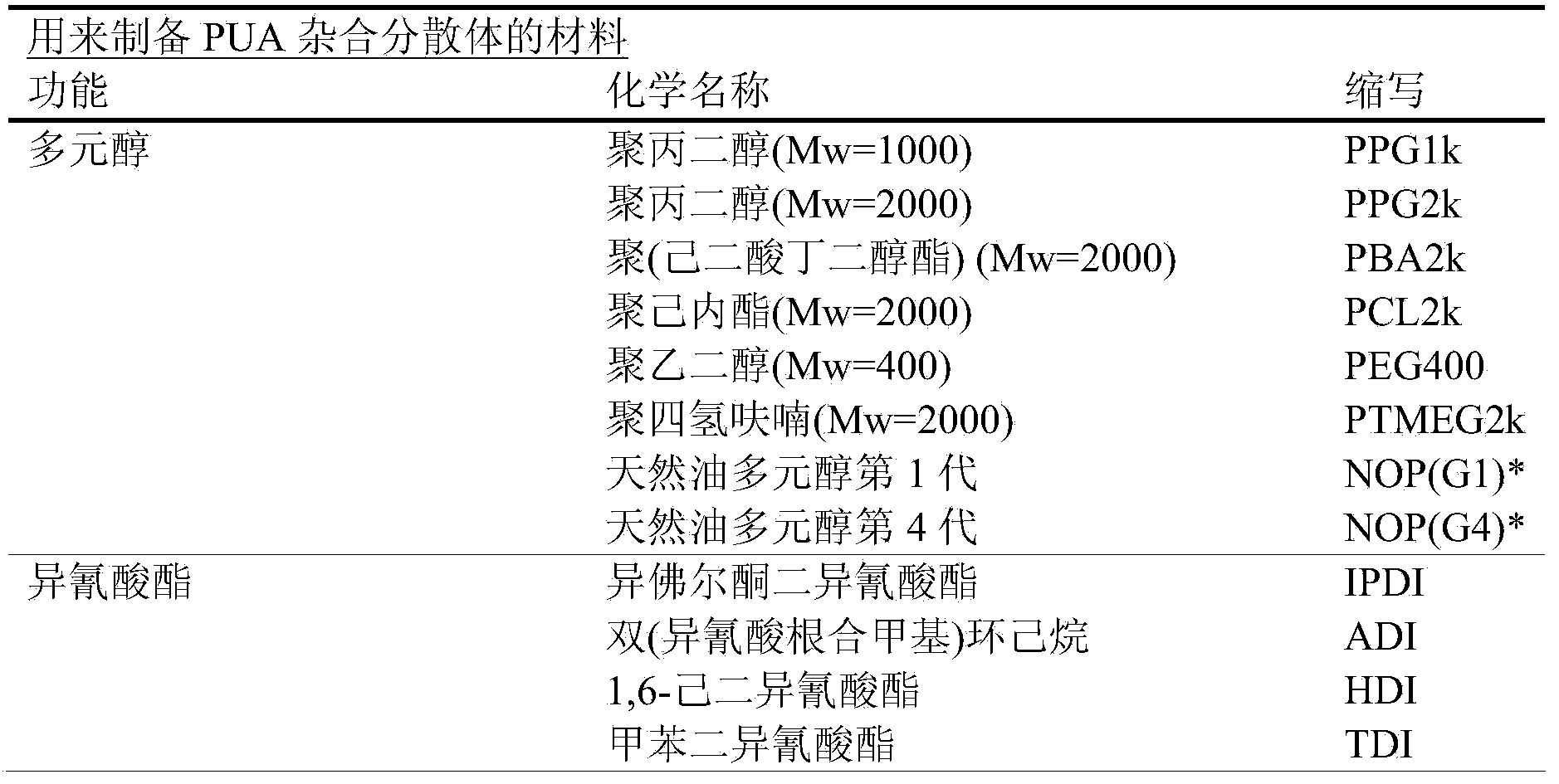

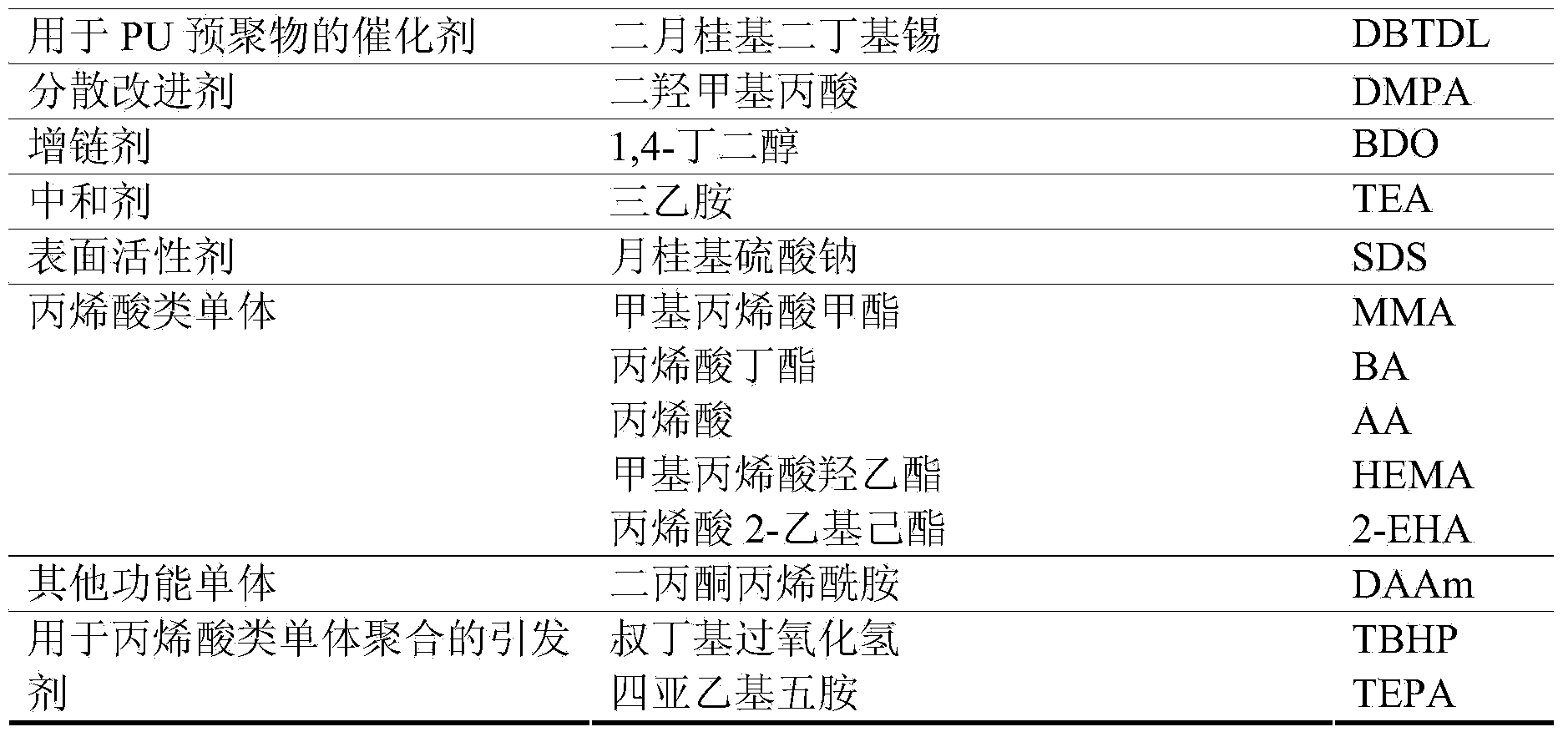

Method used

Image

Examples

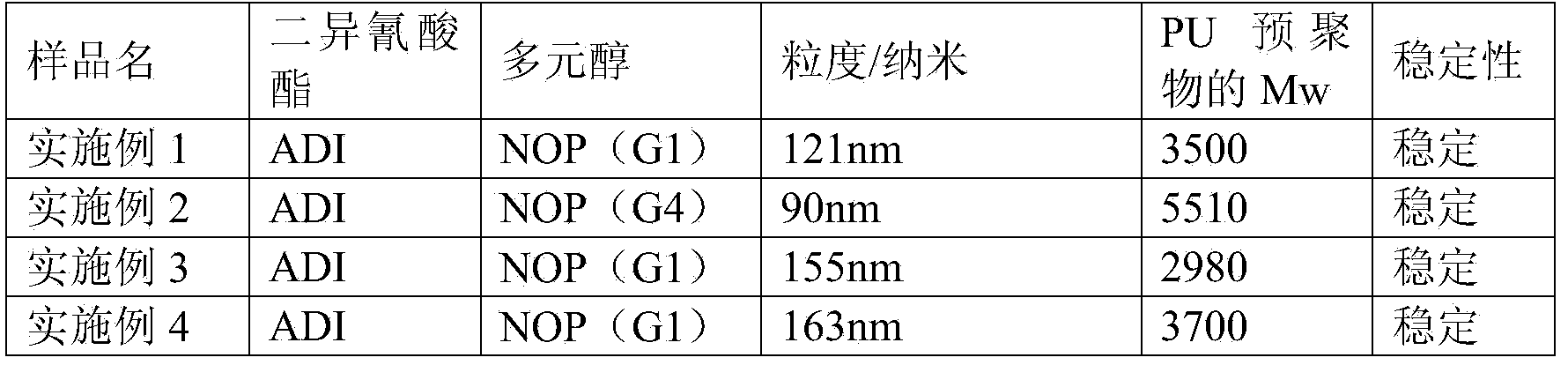

Embodiment 1

[0047] Preparation of PUA Hybrid Dispersion

[0048] (1) 22.4g NOP (G1), 0.04g DBTDL, 22.0g MMA and 2.4g DMPA were added to the three-necked flask, and the flask was stirred and heated;

[0049] (2) when the temperature of reactant reaches 50 ℃, add 11.1 grams of ADI to the flask;

[0050] (3) this reaction is kept at 75 ℃ for 45 minutes;

[0051] (4) 3.3g HEMA was added to the flask, and the reaction was continued for 30 minutes at 80°C;

[0052] (5) Dissolve 3.8g DAAm and 1.9g ammonium hydroxide in 120g deionized water, add the solution to the flask, and stir at 80°C for 30 minutes;

[0053] (6) this reactant is cooled to 60 ℃, 8.0g BA is added to the flask;

[0054] (7) 0.15 g of TBHP solution and 0.3 g of TEPA were separately added to the flask, and the reaction was stirred at 60°C for 1 hour. In some cases, ADH can be added.

[0055] (8) Filter the dispersion with a 100-mesh filter cloth, and the product is denoted as the PUA hybrid dispersion of Example 1.

Embodiment 2

[0057] The procedure of Example 1 was followed, with the difference that NOP (G4) was used as the polyol in this sample.

Embodiment 3

[0059] The steps of Example 1 were repeated, except that the reaction conditions of step (3) were kept at 70° C. for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com