Modified silicone sealant for asphalt pavement crack treatment and preparation method thereof

A technology of asphalt pavement and modified silicon, applied in the field of sealant, can solve the problems that cracks in asphalt pavement cannot be treated, the leveling property of modified silicone sealant and low temperature stretching are not ideal, etc. Improvement, high mechanical strength and bond strength, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

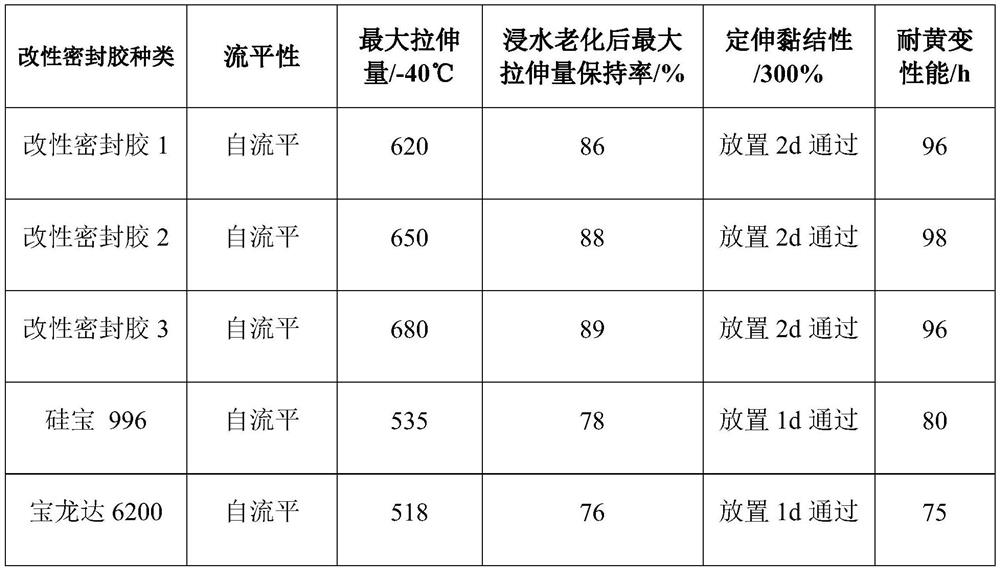

Image

Examples

Embodiment 1

[0018] The invention provides a modified silicone sealant for crack treatment of asphalt pavement, which is specifically prepared through the following steps:

[0019] Step 1: Preparation of modified polyurethane prepolymer raw materials

[0020] Step A1: Preparation of organic modified nano-ion Ⅰ

[0021] S1: In parts by weight: Weigh 10 parts of calcium carbonate inorganic nano filler particles, 30 parts of sodium methoxide solution, and 35.3 parts of ethylene glycol, and set aside;

[0022] S2: Add the calcium carbonate inorganic nano-filler particles and sodium methoxide solution weighed in step S1 into the reactor, and control the reactor to stir for 50 minutes under ultrasonic conditions at normal temperature and pressure to obtain preliminary modified particles;

[0023] S3: After washing the preliminary modified particles obtained in step S2 with anhydrous methanol for 3 times, drying in the temperature range of 50-70° C. for 30 minutes, grinding and sieving to obtain...

Embodiment 2

[0046] The invention provides a modified silicone sealant for crack treatment of asphalt pavement, which is specifically prepared through the following steps:

[0047] Step 1: Preparation of modified polyurethane prepolymer raw materials

[0048] Step A1: Preparation of organic modified nano-ion Ⅰ

[0049] S1: In parts by weight: Weigh 13 parts of fly ash inorganic nano filler particles, 36 parts of sodium ethoxide solution, and 42 parts of glycidol, and set aside;

[0050] S2: Add the fly ash inorganic nano-filler particles and sodium alkoxide solution weighed in step S1 into the reactor, and control the reactor to stir for 55 minutes under ultrasonic conditions at normal temperature and pressure to obtain preliminary modified particles;

[0051] S3: After washing the preliminary modified particles obtained in step S2 with anhydrous methanol for 3 times, drying in the temperature range of 50-70° C. for 33 minutes, grinding and sieving to obtain the first pretreated product w...

Embodiment 3

[0074] The invention provides a modified silicone sealant for crack treatment of asphalt pavement, which is specifically prepared through the following steps:

[0075] Step 1: Preparation of modified polyurethane prepolymer raw materials

[0076] Step A1: Preparation of organic modified nano-ion Ⅰ

[0077] S1: in parts by weight: weigh 15 parts of calcium carbonate inorganic nano filler particles, 40 parts of sodium methoxide solution, and 45 parts of propylene glycol, and set aside;

[0078] S2: Add the calcium carbonate inorganic nano-filler particles and sodium methoxide solution weighed in step S1 into the reactor, and control the reactor to stir for 60 minutes under ultrasonic conditions at normal temperature and pressure to obtain preliminary modified particles;

[0079] S3: After washing the preliminary modified particles obtained in step S2 with anhydrous methanol for 3 times, drying in the temperature range of 50-70° C. for 25 minutes, grinding and sieving to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com