Anti-storage yellowing agent for nylon and preparation method of anti- storage yellowing agent

A yellowing agent, nylon technology, applied in textile and papermaking, fiber processing, fiber type and other directions, can solve problems affecting product use and value, affecting product appearance, etc., to reduce raw material inventory pressure, improve quality and value, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

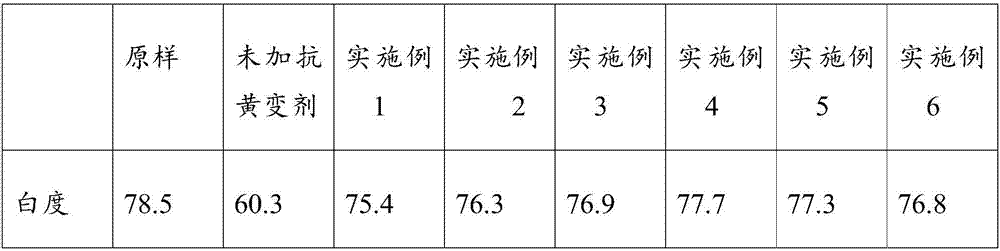

Examples

Embodiment 1

[0025] An anti-storage yellowing agent for nylon, which is composed of the following components by mass percentage, 40% of linear alkylbenzene sulfonic acid, 25% of alcohol amine compounds, 12% of alcohol co-solvent, and 3% of anionic surfactant , non-ionic surfactant 5%, preservative 0.08%, and the balance is deionized water.

[0026] The linear alkylbenzene sulfonic acid of this embodiment is the alkylbenzene sulfonic acid whose chain length is C12; the alcohol amine compound is methyldiethanolamine, diglycolamine mixed in the ratio of mass ratio 2:3; The solvent is ethanol and isopropanol mixed in a mass ratio of 1:2; the anionic surfactant is secondary alkyl sulfonate SAS60; the nonionic surfactant is alkyl glycoside APG and fatty alcohol polyoxyethylene ether AEO9 by mass Mixed in a ratio of 2:3; preservative is sodium benzoate; deionized water is obtained by reverse osmosis, ion exchange resin, filter membrane, etc. to remove ions and impurities in the water.

[0027] T...

Embodiment 2

[0033] An anti-storage yellowing agent for nylon, which consists of the following components by mass percentage, 25% of linear alkylbenzene sulfonic acid, 14% of alcohol amine compounds, 10% of alcohol co-solvent, and 1% of anionic surfactant , 3% non-ionic surfactant, 0.1% preservative, and the balance is deionized water.

[0034] The straight-chain alkylbenzenesulfonic acid of the present embodiment is the alkylbenzenesulfonic acid whose chain length is C16, the alcohol amine compound is diglycolamine, and the alcohol cosolvent is ethanol; the anionic surfactant is secondary alkylsulfonic acid Salt SAS60, nonionic surfactant is fatty alcohol polyoxyethylene ether AEO9, preservative is sodium benzoate.

[0035] Deionized water is obtained by using reverse osmosis method, applying ion exchange resin, filter membrane, etc. to remove ions and impurities in water.

[0036] A preparation method of an anti-storage yellowing agent for nylon, the specific preparation steps are:

[...

Embodiment 3

[0043] An anti-storage yellowing agent for nylon, consisting of the following components by mass percentage, 20% of linear alkylbenzene sulfonic acid, 15% of alcohol amine compounds, 18% of alcohol co-solvent, and 1% of anionic surfactant , Non-ionic surfactant 3%, preservative 0.05%, deionized water 42.95%.

[0044] The linear alkylbenzene sulfonic acid of the present embodiment is the alkylbenzene sulfonic acid that chain length is C16; Alcohol amine compound is ethanolamine; Alcohol cosolvent is isopropanol; Anionic surfactant is linear alkyl sulfonic acid Salt LAS; nonionic surfactant is coconut fatty acid monoethanolamide; preservative is C12 alkyl dimethyl benzyl ammonium chloride. Deionized water is obtained by using reverse osmosis method, applying ion exchange resin, filter membrane, etc. to remove ions and impurities in water.

[0045] A preparation method of an anti-storage yellowing agent for nylon, the specific preparation steps are:

[0046] Step 1: Calculate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com