UV (ultraviolet) white coating system, preparation method and coating process

A coating and system technology, applied in coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of high b value, coating aging, low L value, etc., and achieve good coating effect and attached Good focus, good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

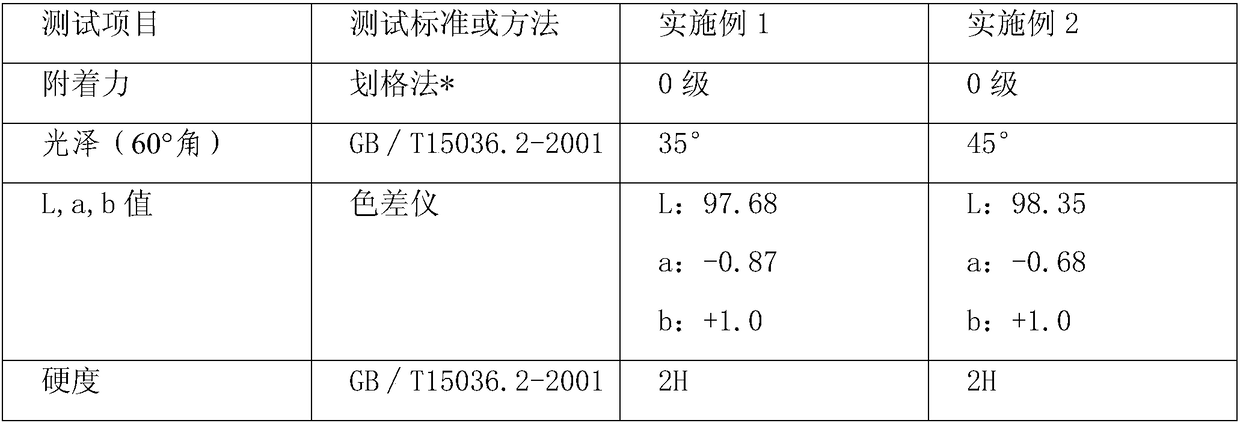

Examples

Embodiment 1

[0045] UV high adhesion transparent primer:

[0046] Fatty acid modified epoxy acrylate: 18%

[0047] Difunctional aliphatic polyurethane: 17%

[0048] Pure acrylate: 12%

[0049] 1,6-Hexanediol diacrylate: 13%

[0050] Hydroxyethyl methacrylate: 10%

[0051] 1250 mesh talcum powder: 20%

[0052] Photoinitiator: 5%

[0053] Auxiliary: 5%

[0054] UV super white primer:

[0055] Modified epoxy acrylate: 18%

[0056] Difunctional polyester acrylate: 12%

[0057] 1,6-Hexanediol diacrylate: 10%

[0058] Dipropylene glycol diacrylate: 10%

[0059] Imported rutile titanium dioxide: 40%

[0060] Photoinitiator: 7%

[0061] Auxiliary: 3%

[0062] UV super white finish:

[0063] Hexafunctional aliphatic polyurethane: 19%

[0064] Difunctional aliphatic polyurethane: 11%

[0065] Trimethylolpropane Triacrylate: 10%

[0066] Dipropylene glycol diacrylate: 10%

[0067] Imported rutile titanium dioxide: 35%

[0068]Imported matting powder: 7%

[0069] Photoinitiator: 6%...

Embodiment 2

[0075] UV high adhesion clear primer:

[0076] Modified epoxy acrylate: 20%

[0077] Difunctional aliphatic polyurethane: 15%

[0078] Pure acrylate: 10%

[0079] 1,6-Hexanediol diacrylate: 15%

[0080] Hydroxyethyl methacrylate: 10%

[0081] 1250 mesh talcum powder: 20%

[0082] Photoinitiator: 5%

[0083] Auxiliary: 5%

[0084] UV super white primer:

[0085] Modified epoxy acrylate: 15%

[0086] Difunctional polyester acrylate: 15%

[0087] 1,6-Hexanediol diacrylate: 10%

[0088] Dipropylene glycol diacrylate: 10%

[0089] Imported rutile titanium dioxide: 40%

[0090] Photoinitiator: 8%

[0091] Auxiliary: 2%

[0092] UV super white finish:

[0093] Hexafunctional aliphatic polyurethane: 20%

[0094] Difunctional aliphatic polyurethane: 10%

[0095] Trimethylolpropane Triacrylate: 10%

[0096] Dipropylene glycol diacrylate: 10%

[0097] Imported rutile titanium dioxide: 35%

[0098] Imported matting powder: 6%

[0099] Photoinitiator: 7%

[0100] Auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com