UV matte white finish paint on melamine board and preparation of UV matte white finish paint

A technology of white topcoat and melamine, which is applied in coatings, epoxy resin coatings, etc., can solve the problems of complex manufacturing process, low coating efficiency, and high comprehensive cost, and achieve uniform gloss, good yellowing resistance, and dry paint film good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

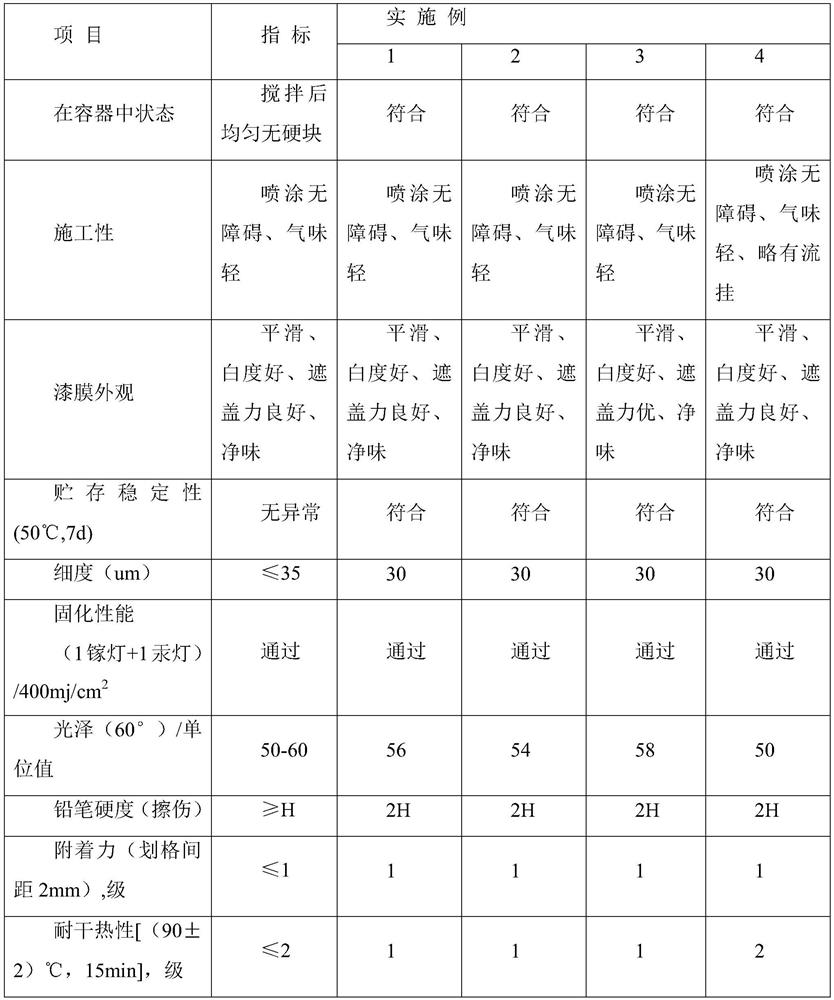

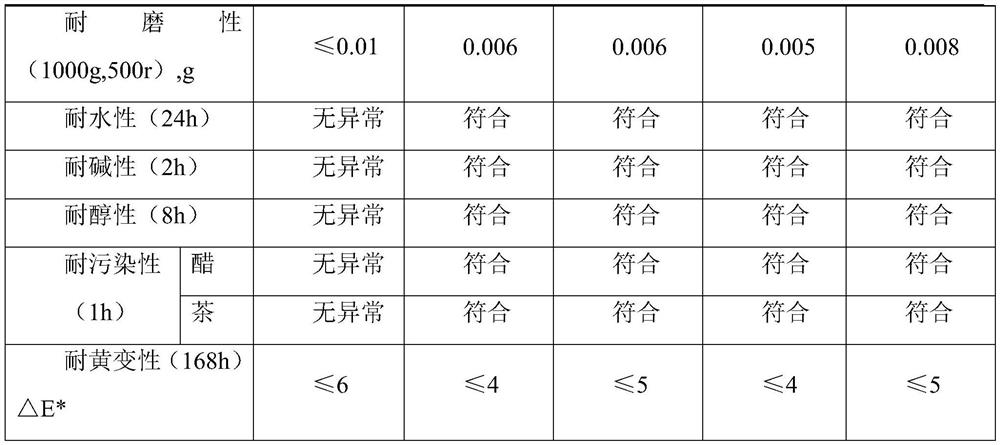

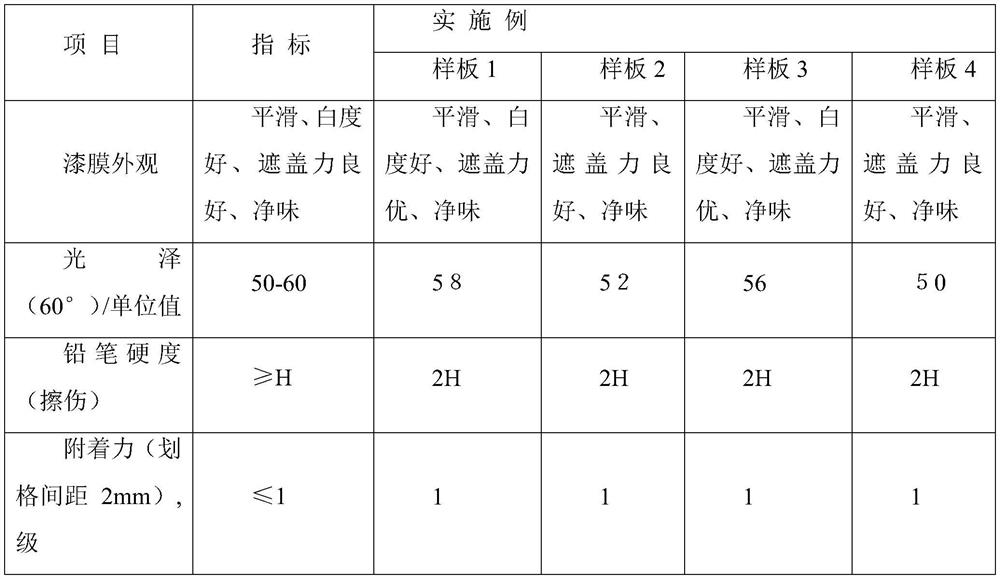

Examples

Embodiment 1

[0035] Raw materials for the preparation of component A: modified UV adhesion resin 15g, modified UV acrylic resin 15g, modified epoxy acrylic resin 15g, dipropylene glycol diacrylate (DPGDA) 10g, hydroxyethyl methacrylate (HEMA ) 5g, acrylic copolymer dispersant 0.8g, rheology additive 0.2g, substrate wetting agent 0.3g, non-silicon defoamer 0.5g, fluorocarbon modified polymer leveling agent 0.2g, 184 photoinitiator 3g , 2 g of GR-TPO photoinitiator, 0.5 g of fumed silica, 10 g of imported rutile titanium dioxide, 5 g of matting powder, 10 g of cellulose acetate butyrate solution, and 7.5 g of butyl acetate.

[0036] Raw materials for preparing component B: 30 g of ethyl acetate, 65 g of butyl acetate, and 5 g of propylene glycol methyl ether acetate.

[0037] Prepare the UV Matte White Topcoat as follows:

[0038] 1) Preparation of component A: Stir the modified UV adhesion resin, modified UV acrylic resin, modified epoxy acrylic resin, and dipropylene glycol diacrylate at ...

Embodiment 2

[0043] Compared with Example 1, the content of each component in A and B is different

[0044] Raw materials for the preparation of component A: modified UV adhesion resin 20g, modified UV acrylic resin 12g, modified epoxy acrylic resin 15g, dipropylene glycol diacrylate (DPGDA) 15g, hydroxyethyl methacrylate (HEMA ) 3g, acrylic copolymer dispersant 0.8g, rheology additive 0.2g, substrate wetting agent 0.3g, non-silicon defoamer 0.5g, fluorocarbon modified polymer leveling agent 0.2g, 184 photoinitiator 3g , 2 g of GR-TPO photoinitiator, 0.5 g of fumed silica, 10 g of imported rutile titanium dioxide, 5 g of matting powder, 5 g of cellulose acetate butyrate solution, and 7.5 g of butyl acetate.

[0045] Raw materials for preparing component B: 20 g of ethyl acetate, 75 g of butyl acetate, and 5 g of propylene glycol methyl ether acetate.

Embodiment 3

[0047] Optimum embodiment, compared with embodiment 1, the content of each component in A and B is different

[0048] Raw materials for the preparation of component A: 20g of modified UV adhesion resin, 10g of modified UV acrylic resin, 15g of modified epoxy acrylic resin, 7.5g of dipropylene glycol diacrylate (DPGDA), hydroxyethyl methacrylate ( HEMA) 5g, acrylic copolymer dispersant 1g, rheology additive 0.3g, substrate wetting agent 0.3g, non-silicon defoamer 0.5g, fluorocarbon modified polymer leveling agent 0.3g, 184 photoinitiator 2.5 g, 2.5g of GR-TPO photoinitiator, 0.8g of fumed silica, 15g of imported rutile titanium dioxide, 5g of matting powder, 10g of cellulose acetate butyrate solution, and 4.3g of butyl acetate.

[0049] Raw materials for preparing component B: 20 g of ethyl acetate, 72 g of butyl acetate, and 8 g of propylene glycol methyl ether acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com