Scratch-resistant BOPP (biaxially-oriented polypropylene) film and preparation method thereof

A scratch-resistant and thin-film technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low surface energy of the film, difficulty in uniform dispersion of nano-silica particles, and poor binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

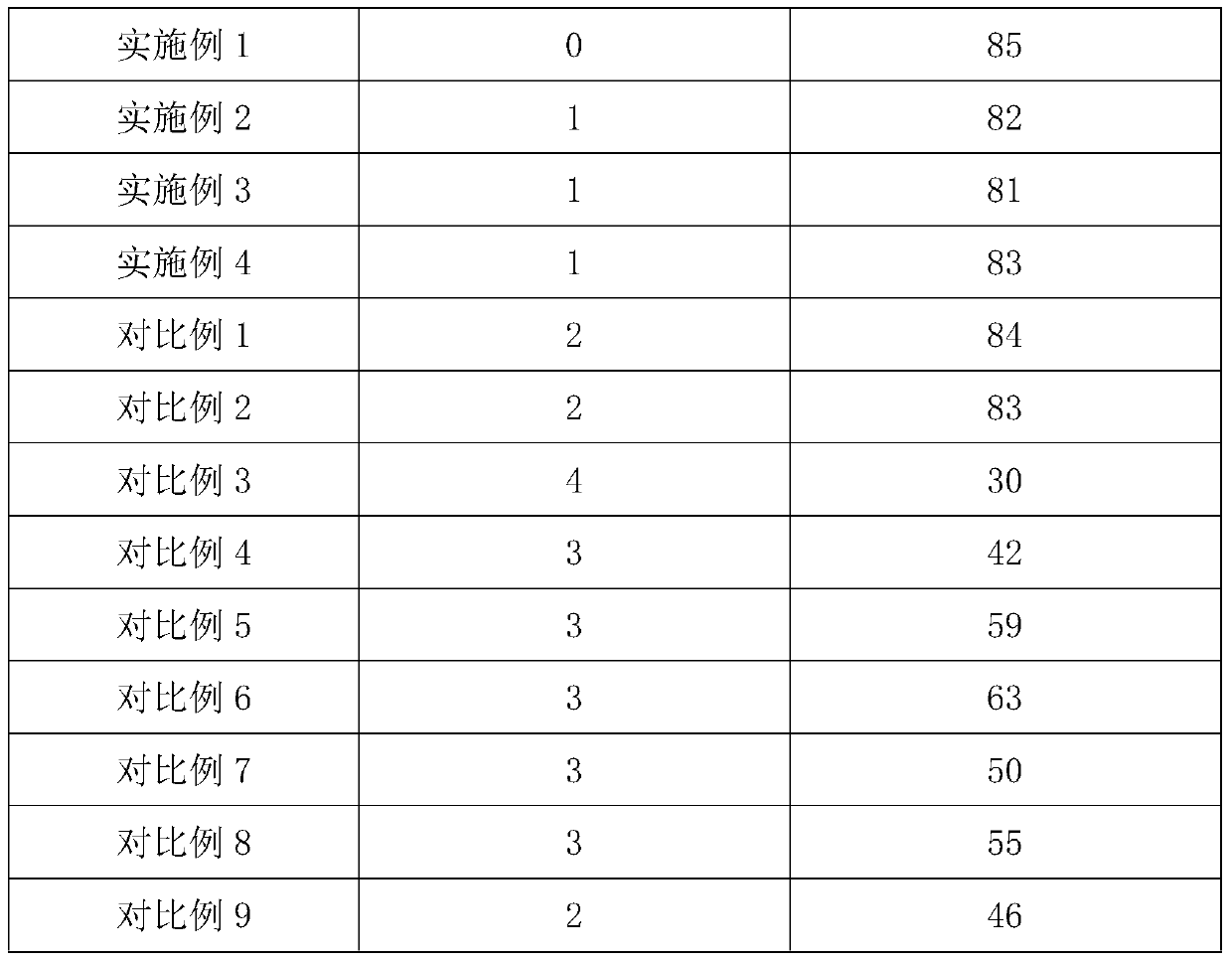

Examples

Embodiment 1~4

[0029] A preparation method for scratch-resistant BOPP film, the steps are:

[0030] (1) Corona treatment is performed on the BOPP film substrate to generate oxygen-containing polar groups on its surface;

[0031] (2) Add nano silicon dioxide to toluene, and obtain a uniform suspension after ultrasonic dispersion at room temperature, add silane coupling agent KH-550 with a mass fraction of silicon dioxide of 4%, reflux at 110°C for 2 hours, and suction filter, After washing and drying with absolute ethanol, KH-550 modified nano silicon dioxide is obtained;

[0032] (3) Weigh aliphatic urethane acrylate hexaacrylate (HY330), dipropylene glycol diacrylate (Changxing EM222), KH-550 modified nano silica, defoamer (BYK1770) and Wetting agent (BYK-P104S), after ultrasonic dispersion at room temperature for 40 minutes, add the formulated amount of photoinitiator 1173, stir evenly, and obtain scratch-resistant coating;

[0033] (4) Coating the anti-scratch coating on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com