Hydrographic transfer printing ink and preparation method thereof

A water transfer printing and ink technology, applied in ink, household appliances, applications, etc., can solve problems such as high energy consumption, environmental, human body hazards, and volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

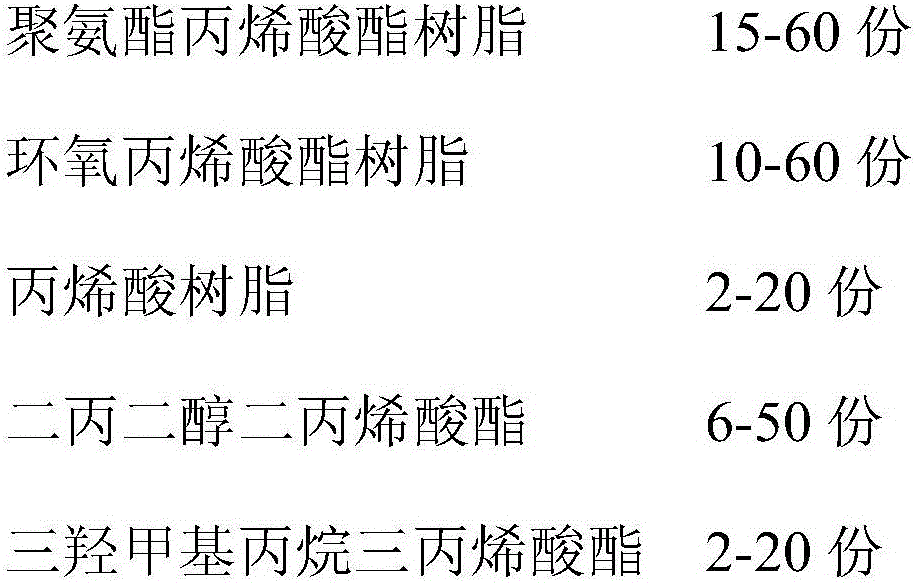

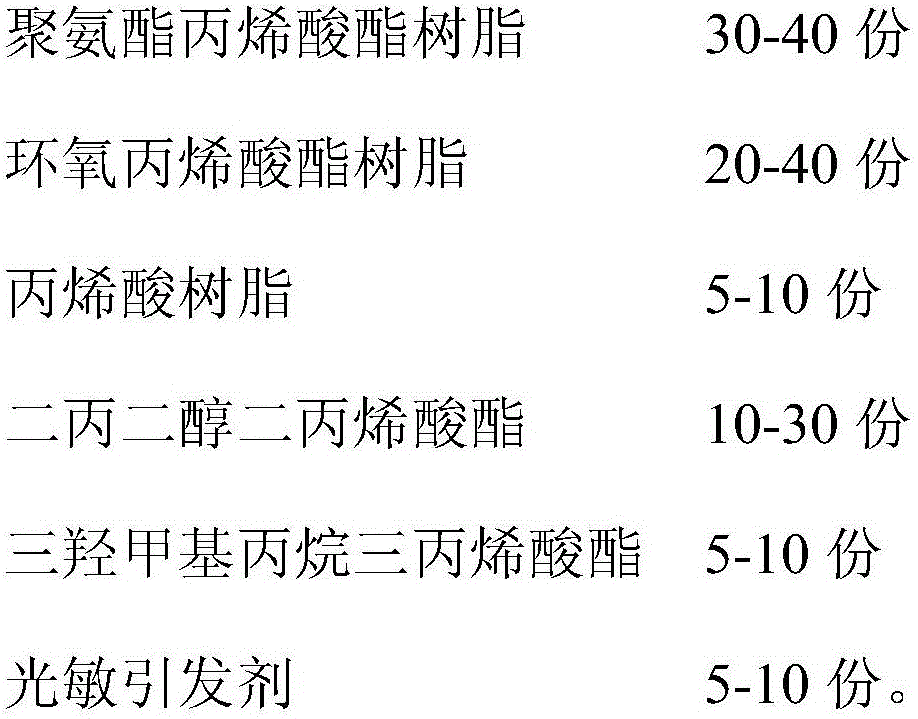

Method used

Image

Examples

Embodiment 1

[0052] Raw materials contain by weight: 30 parts of polyurethane acrylate resin, 20 parts of epoxy acrylate resin, 5 parts of acrylic resin, 10 parts of dipropylene glycol diacrylate, 5 parts of trimethylol propane triacrylate, 5 parts of photoinitiator 3 parts, 3 parts of organic pigment, 0.1 part of defoamer, 0.2 part of dispersant, 0.1 part of leveling agent.

[0053] The photoinitiator is 4-phenylbenzophenone and diphenylphosphine; the organic pigment is permanent violet; the defoamer is a polymer defoamer; the dispersant is a block copolymer containing pigment affinity groups Material; leveling agent is polyether modified polydimethylsiloxane.

[0054] The specific preparation method is as follows:

[0055] (1) According to the number of parts, urethane acrylate resin, epoxy acrylate resin, acrylic resin, dipropylene glycol diacrylate, and trimethylolpropane triacrylate are sequentially fed and stirred for 10-30 minutes until uniform, and the stirring speed is 800 -1000...

Embodiment 2

[0065] Raw materials contain by weight: 35 parts of polyurethane acrylate resin, 30 parts of epoxy acrylate resin,

[0066] 8 parts of acrylic resin, 20 parts of dipropylene glycol diacrylate, 8 parts of trimethylolpropane triacrylate, 8 parts of photoinitiator, 0 parts of organic pigment, 1 part of defoamer, 1 part of dispersant, and leveling agent 1 serving.

[0067] The photoinitiator is diphenylphosphine; the defoamer is a polymer defoamer; the dispersant is a block copolymer containing pigment affinity groups; the leveling agent is polyether modified polydimethylsiloxane alkyl.

[0068] The specific preparation process is the same as in Example 1.

[0069] The specific printing method and drying conditions thereof are the same as in Example 1.

Embodiment 3

[0071] Raw materials contain by weight: 40 parts of polyurethane acrylate resin, 40 parts of epoxy acrylate resin, 10 parts of acrylic resin, 30 parts of dipropylene glycol diacrylate, 10 parts of trimethylol propane triacrylate, 10 parts of photoinitiator 8 parts, 8 parts of organic pigment, 2 parts of defoamer, 2 parts of dispersant, 2 parts of leveling agent.

[0072] The photoinitiator is 4-phenylbenzophenone; the organic pigment is permanent red; the defoamer is a polymer defoamer; the dispersant is a block copolymer containing pigment affinity groups; the leveling agent is Polyether modified polydimethylsiloxane.

[0073] The specific preparation process is the same as in Example 1.

[0074] The specific printing method and drying conditions thereof are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com