LED-cured water transfer printing varnish cover oil and preparation method thereof

A technology of cover oil and water transfer printing, applied in ink, household utensils, applications, etc., can solve problems such as slow production speed, low efficiency, environment, and human hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

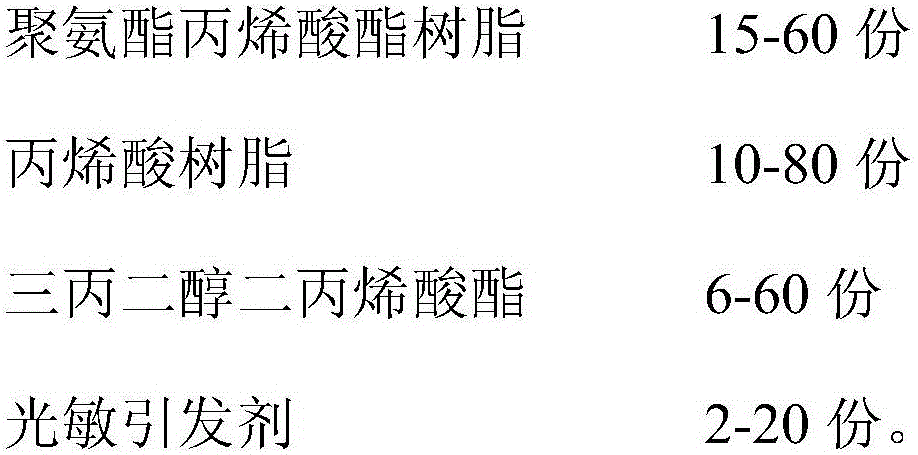

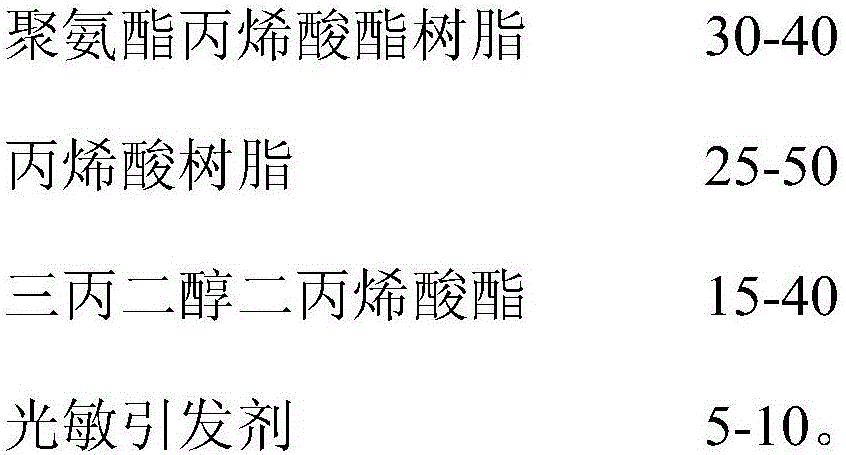

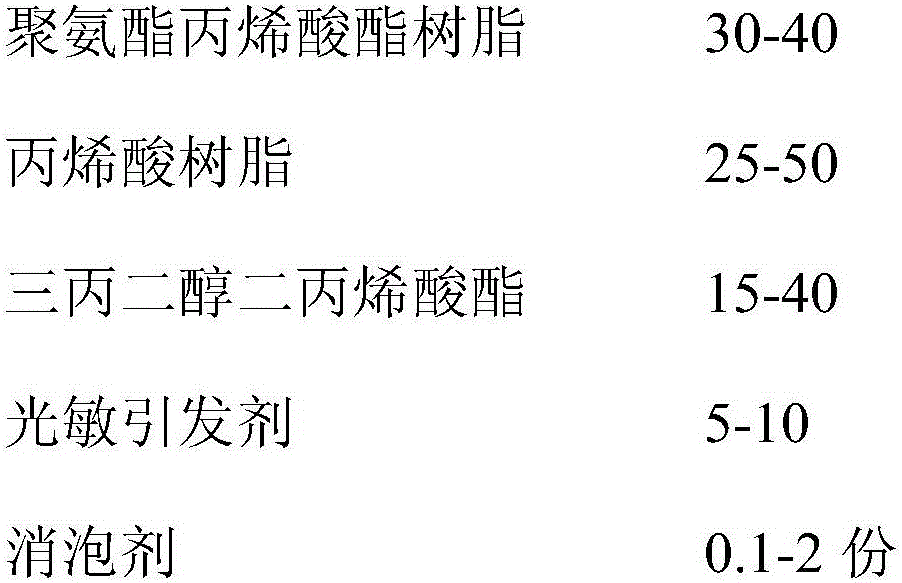

Method used

Image

Examples

Embodiment 1

[0050] The raw materials contain in parts by weight: polyurethane acrylic resin 30, acrylic resin 30, tripropylene glycol diacrylate 25, photoinitiator 5, defoamer 0.1, dispersant 0.2, and leveling agent 0.1.

[0051] The photoinitiator is 4-phenylbenzophenone and diphenyl oxyphosphorus; the defoaming agent is a polymer defoaming agent; the dispersing agent is a block copolymer containing a pigment affinity group; the leveling agent is a polyether Modified polydimethylsiloxane.

[0052] The specific preparation method is as follows:

[0053] (1) According to the number of parts, the polyurethane acrylic resin, acrylic resin, and tripropylene glycol diacrylate are sequentially fed and stirred for 10-30 minutes until uniform, and the stirring speed is 800-1000 rpm.

[0054] (2) Add the remaining items according to the number of parts, and stir for 5-10 minutes at a stirring speed of 500-800 rpm.

[0055] (3) Use a three-roll machine to grind the mixed ink 4-6 times. The film thickness of...

Embodiment 2

[0062] The raw materials contain in parts by weight: polyurethane acrylate resin 35, acrylic resin 40, tripropylene glycol diacrylate 30, photoinitiator 8, defoamer 1, dispersant 1, and leveling agent 1.

[0063] Photoinitiator is 4-phenylbenzophenone; defoamer is polymer defoamer; dispersant is block copolymer with pigment affinity group; leveling agent is polyether modified polydimethyl Siloxane.

[0064] The specific preparation process is the same as in Example 1.

[0065] The specific printing method and its drying conditions are the same as in Example 1.

Embodiment 3

[0067] The raw materials contain in parts by weight: polyurethane acrylate resin 40, acrylate 45, tripropylene glycol diacrylate 35, photoinitiator 10, defoamer 2, dispersant 2, and leveling agent 2.

[0068] Photoinitiator is diphenyl oxyphosphorus; defoamer is polymer defoamer; dispersant is block copolymer containing pigment affinity group; leveling agent is polyether modified polydimethylsiloxane .

[0069] The specific preparation process is the same as in Example 1.

[0070] The specific printing method and its drying conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com