High photoelectric conversion efficiency and high thermal stability perovskite material and preparation method

A technology of photoelectric conversion efficiency and perovskite material, applied in circuits, electrical components, electric solid state devices, etc., can solve the problems of low photoelectric conversion efficiency, poor thermal stability, poor material stability, etc., and achieve high photoelectric conversion efficiency and thermal stability. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] PB 2 Preparation of HI: Take a certain amount of PbI 2 The powder is dissolved in DMF solvent to make a solution with a concentration of 1mol / L. Then slowly add hydroiodic acid (7.58mol / L) dropwise to the aforementioned solution under conditions of ice bath and magnetic stirring, and control HI and PbI 2 The ratio of the amount of substance is 1.3:1. Then magnetic stirring was carried out for 2 hours, and rotary evaporation was carried out at 80 ° C. The crystallized substance was washed with ether three times, and finally dried to obtain PbI 2 HI powder, PbI calculated based on lead content 2 ·The molecular weight of the HI complex is 734.

[0031] EDAI 2 (Ethylenediamine iodine) preparation: Ethylenediamine and hydroiodic acid are mixed at a ratio of 1:2.1, rotary evaporated at 60°C, washed repeatedly with ether, and finally dried to obtain EDAI 2 powder.

Embodiment 1

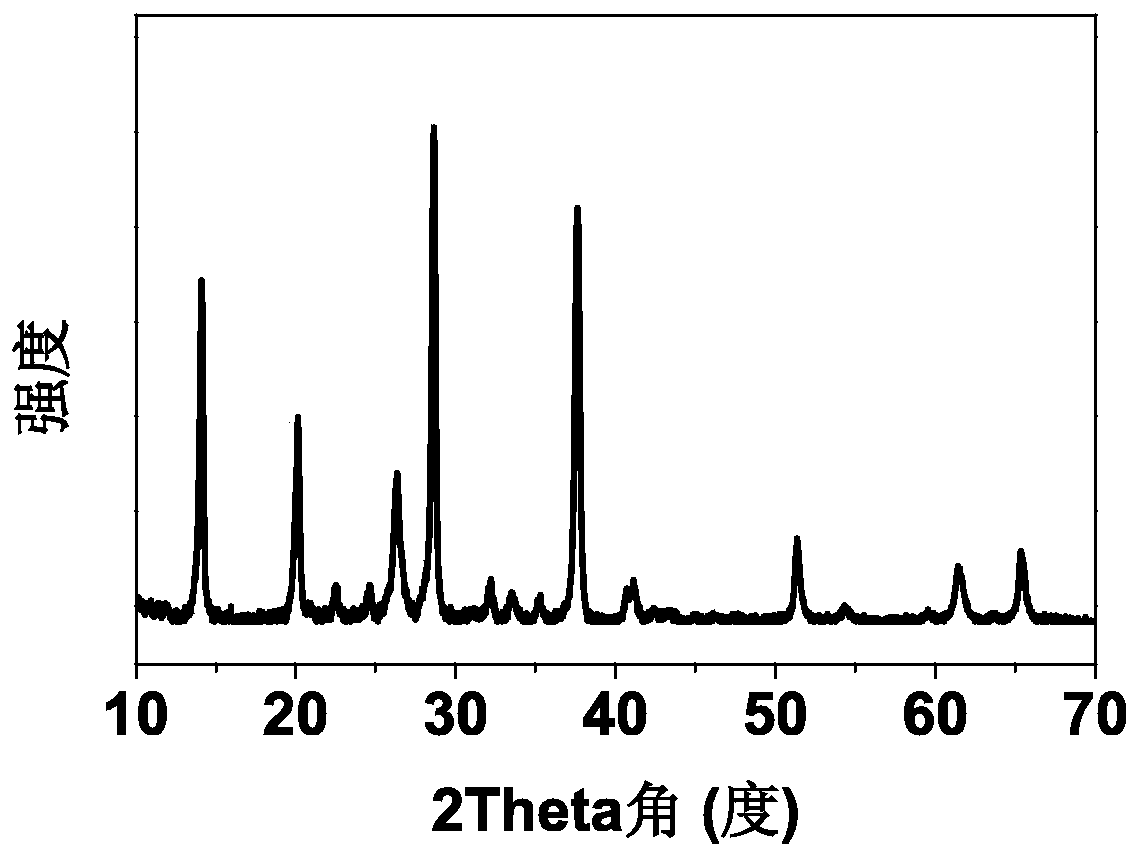

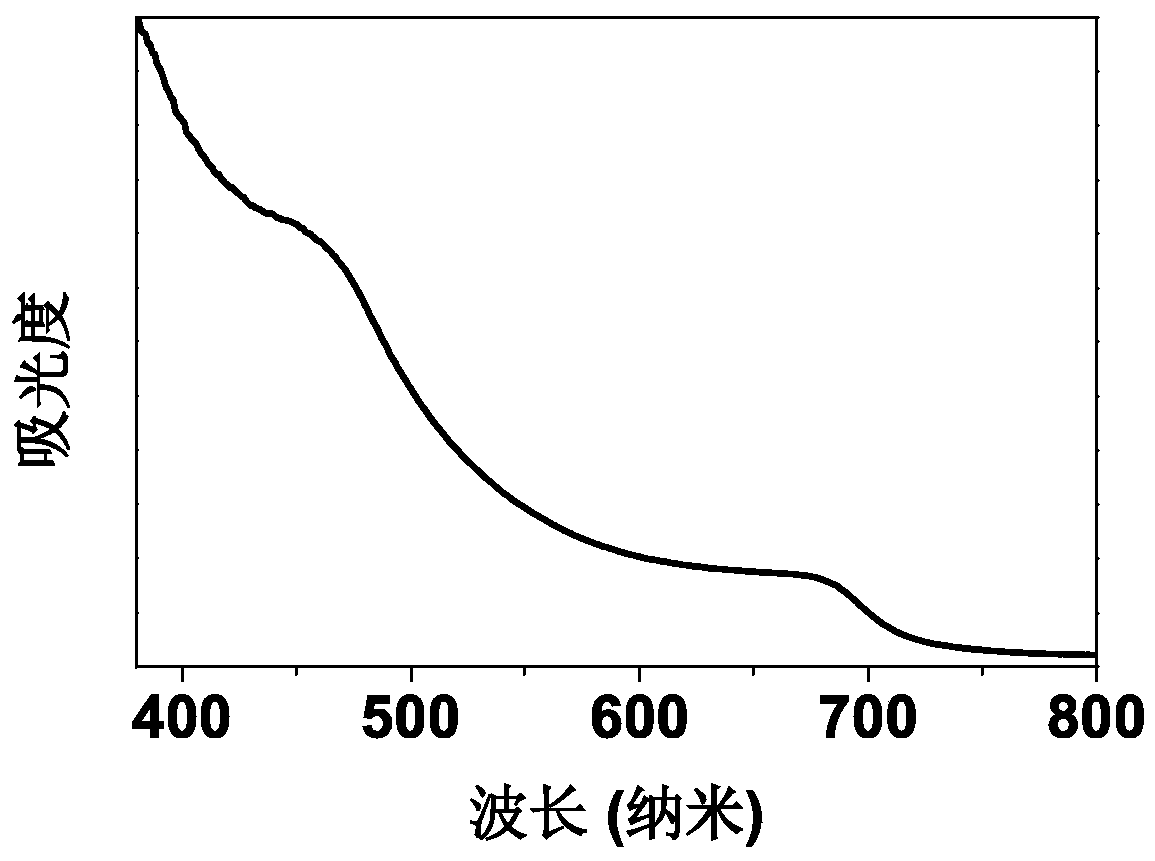

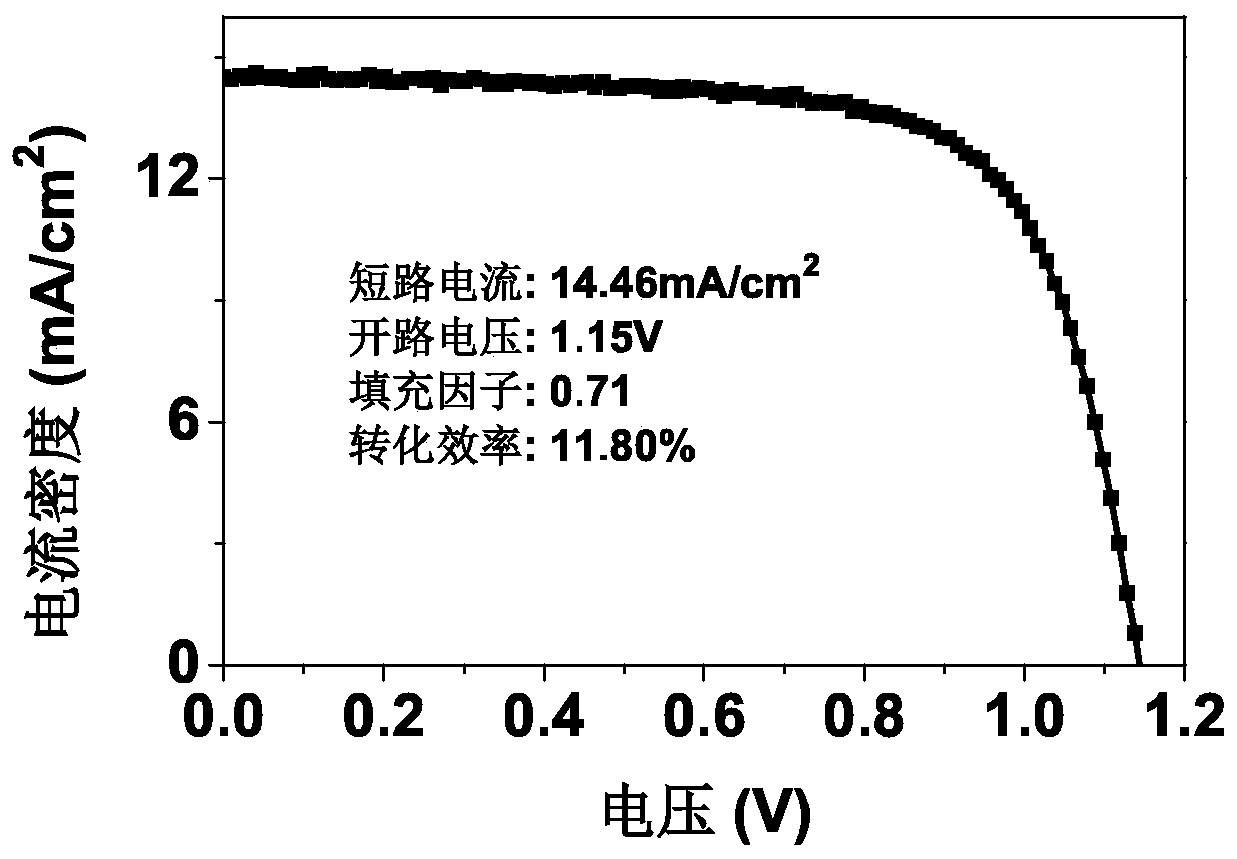

[0033] This embodiment relates to a perovskite material with high photoelectric conversion efficiency and high thermal stability, its molecular formula is, CsPbI 3 0.025 EDAPbI 4 .

[0034] The preparation method of the above-mentioned perovskite material specifically includes the following steps:

[0035] (1) Preparation of perovskite material precursor solution

[0036] 0.316g EDAI 2 and 0.461 g PbI 2 Dissolve in 2ml dimethylformamide to get EDAPbI 4 Solution, denoted as mother solution A; 0.734g PbI 2 · HI complex and 0.259g of CsI were dissolved in 2ml of dimethylformamide, and then 0.05ml of mother liquor A was added.

[0037] EDAPbI above 4 , PbI 2 ·The calculated molar ratio of HI complex and CsI is 0.025:1:1.

[0038] (2), coating of perovskite material

[0039] The precursor solution obtained in step (1) was spin-coated at a rate of 3500 R / min for 30 s and annealed on the substrate at 150° C. for 2 minutes to obtain a substrate coated with a perovskite materia...

Embodiment 2

[0046] The method is the same as in Example 1, the difference is that the solvent is replaced by γ-hydroxybutyrolactone GBL, the amount of mother liquor A added is 0.025ml, and what is obtained is CsPbI 3 0.0125 EDAPbI 4 film.

[0047] EDAPbI above 4 , PbI 2 ·The molar ratio of HI complex and CsI is 0.012:1:1.

[0048] The assembled solar cell efficiency of the sample obtained in Example 2 is 9.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com