UV-curable adhesive composition for compact discs

A kind of adhesive, UV-technology, applied in the direction of non-polymer organic compound adhesives, adhesives, optical recording/reproduction, etc., can solve the problems of easy generation of bubbles, failure to provide, high resistance, etc., to achieve high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In a reactor equipped with a stirrer and a thermometer, 50 parts of bisphenol A diglycidyl ether diacrylate (trade name CNUVE151, manufactured by Sartomer), 10 parts of isobornyl acrylate (IBOA, SR506), 5 parts of ethoxy Trimethylolpropane triacrylate (EO-TMPTA, SR454), 25 parts of tricyclodecane dimethylol diacrylate (SR833S, R-684), 10 parts of phenoxyethyl acrylate (R-561 ), 3 parts of 2,4,6-(trimethylbenzoyl) diphenylphosphine oxide (TPO, DAROCUR TPO), 1 part of γ-methacryloxypropyl trimethoxysilane (Silquest A-174 Silane), and dissolved at 60°C for 1 hour to prepare the UV-curable adhesive composition of the present invention. The prepared UV-curable adhesive composition of the present invention has a viscosity of 500 MPa·s at 25° C. (measured by a NDJ-5S viscometer).

[0026] According to the following DVD9 conventional bonding steps 1-4, the silver alloy semi-permeable film reflective film substrate and the silicon dioxide / zinc oxide protective inorganic film s...

Embodiment 2-6

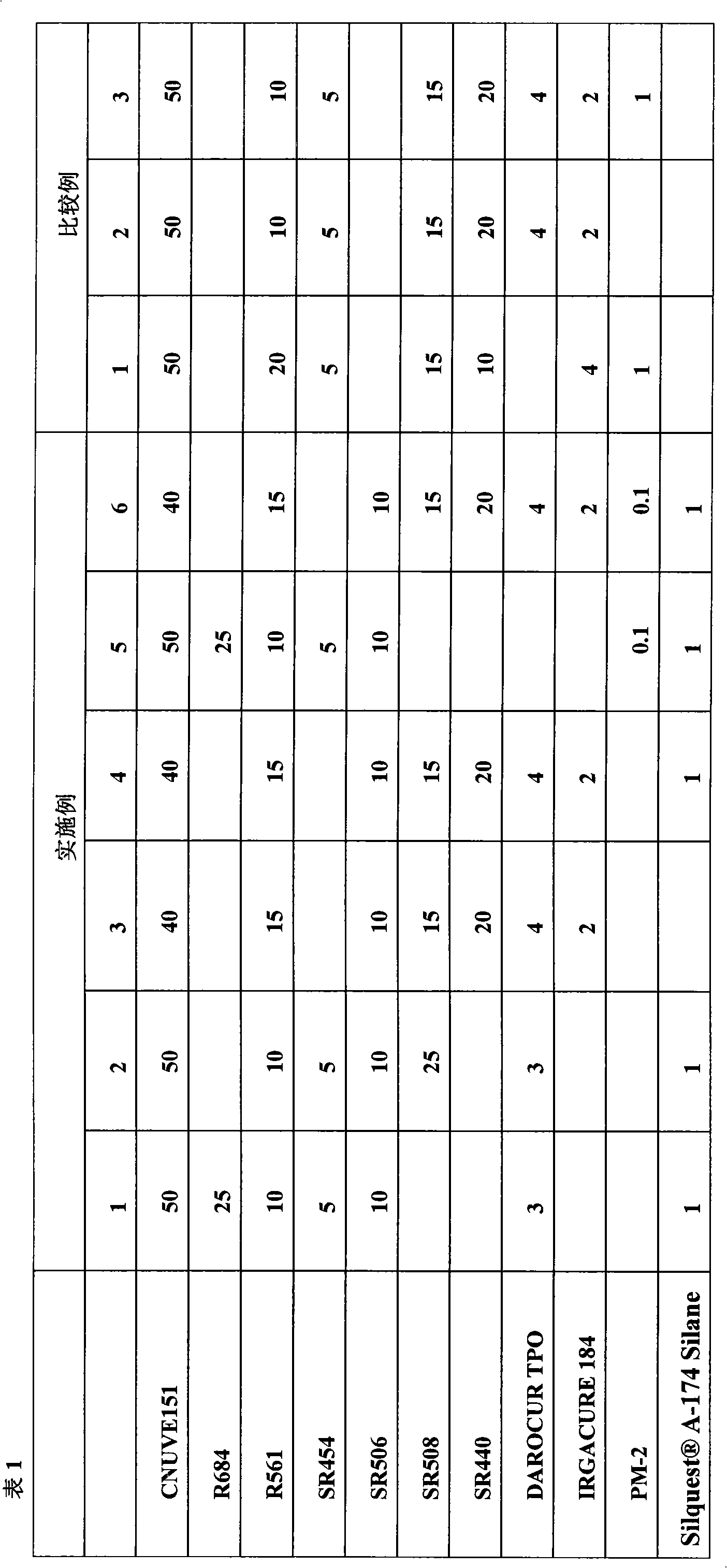

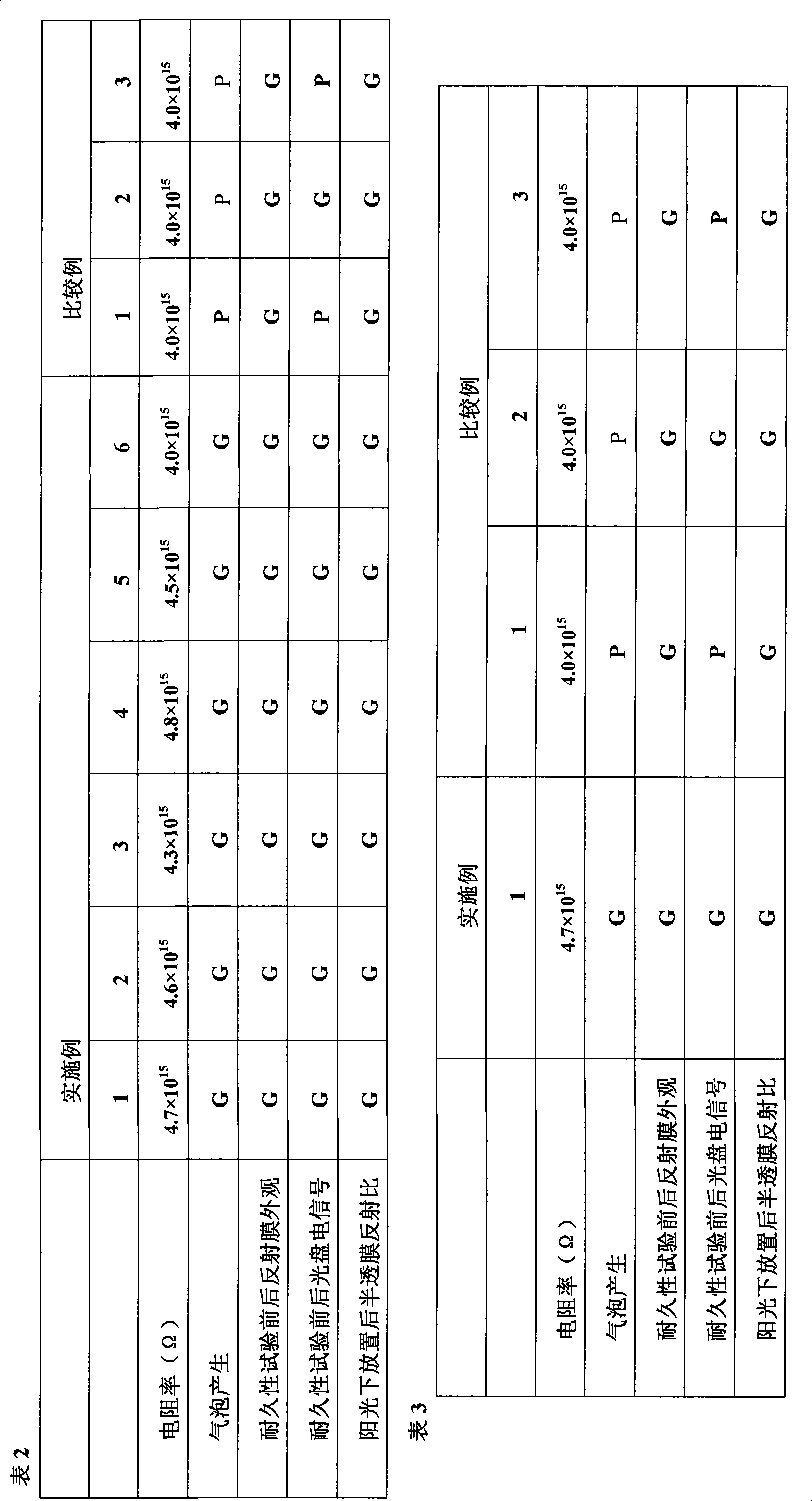

[0031] Embodiment 2-6, comparative example 1-3

[0032] UV-curable adhesive compositions of Examples 2-6 and Comparative Examples 1-3 were prepared in the same manner as Example 1. The discs were bonded in the same manner as in Example 1.

[0033] Among them, comparative examples 1-3 are UV curable adhesives currently used in industry to bond metals.

[0034] The ratio of each component of the UV-curable adhesive composition of each embodiment is shown in Table 1: the numbers in Table 1 represent the number of parts, and the abbreviations of each component are as follows:

[0035] CNUVE151: bisphenol A diglycidyl ether diacrylate obtained from Sartomer CO., LTD

[0036] SR454: Ethoxylated trimethylolpropane triacrylate obtained from Sartomer CO., LTD

[0037] R-684: Tricyclodecane dimethylol diacrylate, available from NIPPON KAYAKU CO., LTD

[0038] R-561: Phenoxyethyl acrylate, available from NIPPON KAYAKU CO., LTD

[0039]DAROCUR TPO: 2,4,6-(trimethylbenzoyl)diphenylpho...

Embodiment 7

[0075] The UV-curable composition prepared in Example 1 was used to bond the two substrates following DVD-R Bonding General Procedures 1-4 below.

[0076] 1. According to a conventional method, a DVD-R pigment layer is formed on a PC substrate with a thickness of 0.6 mm, and grooves are formed on it using a conventional method of DVD-R standards.

[0077] 2. Sputter silver alloy TTP-40A (obtained from Target Technology Company LLC) on the substrate forming the pigment layer, and form the pigment layer thereon, so that the average film thickness on the DVD-R pigment layer is 50-60nm.

[0078] 3. Apply 1.5 g of the UV-curable composition of Example 1 around the silver alloy reflective film formed as above on the circular substrate. A 0.6 mm thick PC substrate was placed thereon and spin-coated at 2000 rpm for 4 seconds to make them adhere. The film thickness of the UV-curable composition was made to be 45-50 μm. An apparatus manufactured by OriginELECTRLC CO.LTD was used as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com