Thermosensitive color-changing microcapsule UV (Ultraviolet) photo-cured printing ink and preparation method thereof

A light-curing ink and heat-sensitive discoloration technology, which is applied in the field of ink, can solve the problems of poor color rendering performance and storage performance, and achieve the effects of good fixing effect, fast drying speed and good environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

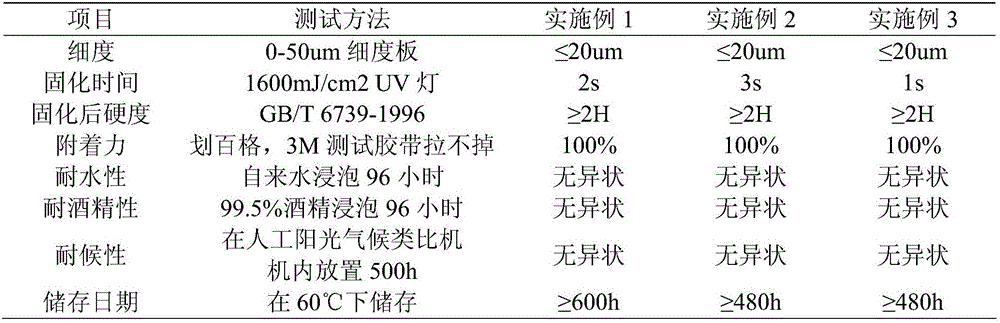

Examples

Embodiment 1

[0026] A heat-sensitive color-changing microcapsule UV light-curable ink, prepared from the following raw materials in parts by weight: 35 parts of epoxy acrylate, 18 parts of color-developing microcapsules, 20 parts of polyester acrylate, 10 parts of dipropylene glycol diacrylate Esters, 5 parts of trimethylolpropane triacrylate, 5 parts of 4-hydroxybutyl acrylate, 5 parts of British EASTAER ED-5940, 1 part of hollow glass microspheres and 1 part of UV varnish.

[0027] The chromogenic microcapsules are prepared through the following steps:

[0028] (1) Preparation of chromogenic microcapsule core material: 8 parts of 2-anilino-3-methyl-6-dibutylaminofluorane (ODB-2), 20 parts of bisphenol A, benzyl-2-naphthalene 15 parts of base ether (BON) were mixed and stirred for 2 hours to obtain the core material;

[0029] (2) Preparation of chromogenic microcapsules:

[0030] ①Take 10L of water, heat it to 50°C, add 250g of Arabic resin and 250g of gelatin, and stir at a speed of 50...

Embodiment 2

[0037] A heat-sensitive color-changing microcapsule UV photocurable ink, prepared from the following raw materials in parts by weight: 35 parts of epoxy acrylate, 20 parts of color-developing microcapsules, 15 parts of polyester acrylate, 10 parts of dipropylene glycol diacrylate ester, 5 parts of trimethylolpropane triacrylate, 7 parts of 4-hydroxybutyl acrylate, 3 parts of Holland Efka EFKA-5210, 3 parts of hollow glass microspheres and 2 parts of UV varnish.

[0038] The chromogenic microcapsules are prepared through the following steps:

[0039] (1) Preparation of chromogenic microcapsule core material: 10 parts of crystal violet lactone (CVL), 20 parts of bisphenol A, and 15 parts of benzyl-2-naphthyl ether (BON) were mixed and stirred for 2 hours to obtain the core material ;

[0040] (2) Preparation of chromogenic microcapsules:

[0041] ①Take 10L of water, heat it to 50°C, add 250g of Arabic resin and 250g of gelatin, and stir at a speed of 5000r / min until completely...

Embodiment 3

[0048] A heat-sensitive color-changing microcapsule UV photocurable ink, prepared from the following raw materials in parts by weight: 30 parts of epoxy acrylate, 18 parts of color-developing microcapsules, 15 parts of polyester acrylate, 15 parts of dipropylene glycol diacrylate Esters, 5 parts of trimethylolpropane triacrylate, 10 parts of 4-hydroxybutyl acrylate, 5 parts of British EASTAER ED-5940, 5 parts of hollow glass microspheres and 2 parts of UV varnish.

[0049] The chromogenic microcapsules are prepared through the following steps:

[0050] (1) Preparation of chromogenic microcapsule core material: 8 parts of 2-anilino-3-methyl-6-dibutylaminofluorane (ODB-2), 20 parts of bisphenol A, tetramethylbenzidine 15 parts of alkane were mixed and stirred for 2 hours to obtain a core material;

[0051] (2) Preparation of chromogenic microcapsules:

[0052] ①Take 10L of water, heat it to 50°C, add 250g of Arabic resin and 250g of gelatin, and stir at a speed of 5000r / min un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com