UV (Ultraviolet light) snowflake printing ink

A technology of snowflake ink and leveling agent, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of low production efficiency, achieve the effect of improving printing efficiency and reducing printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

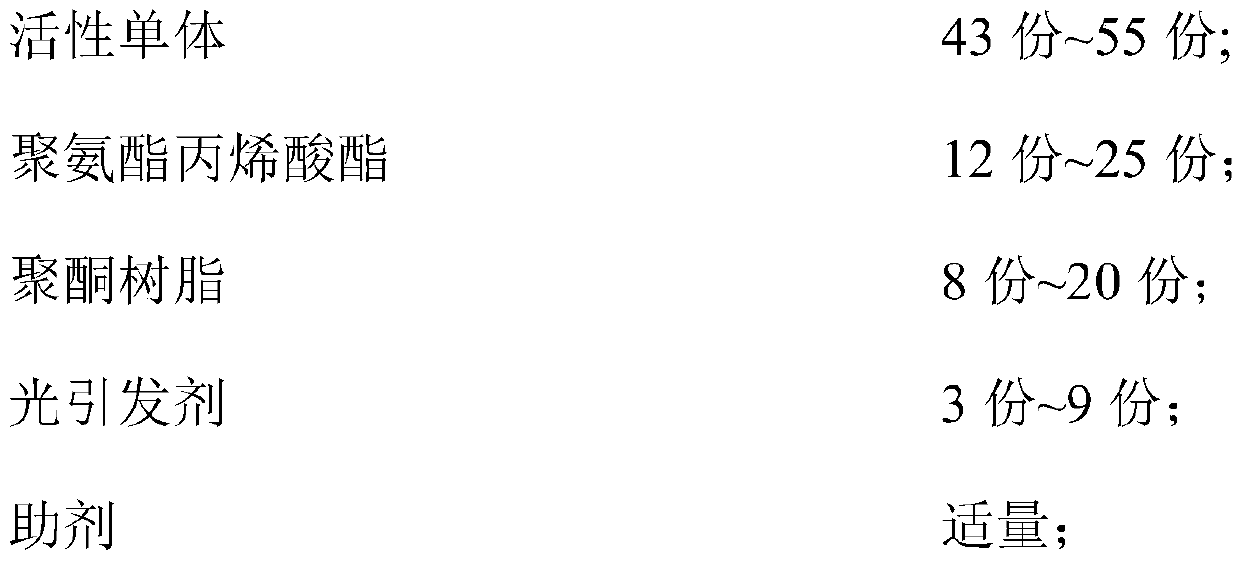

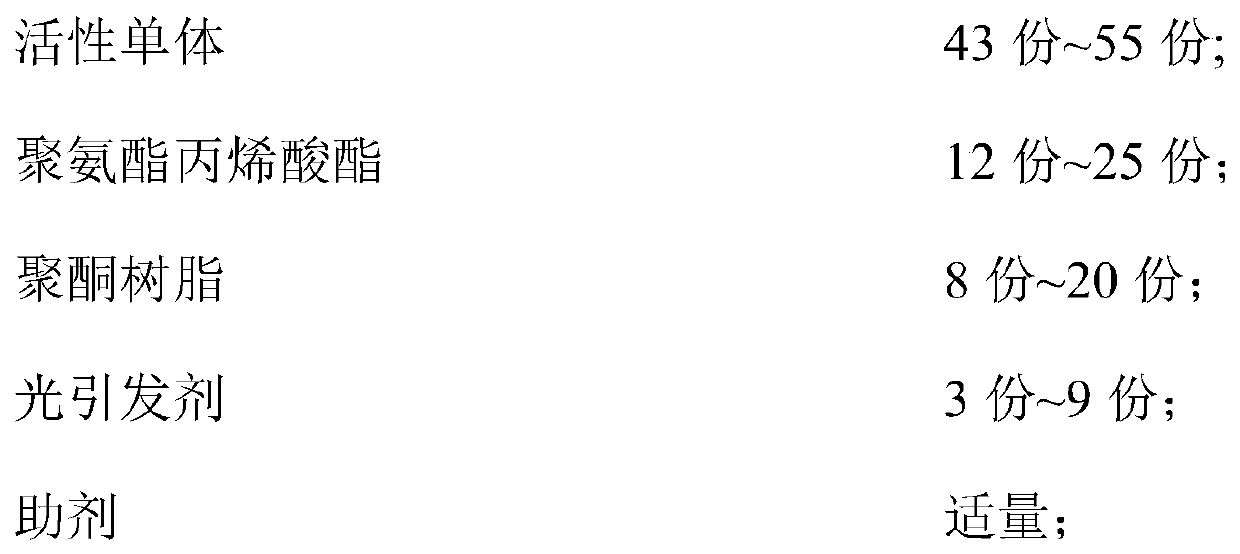

Method used

Image

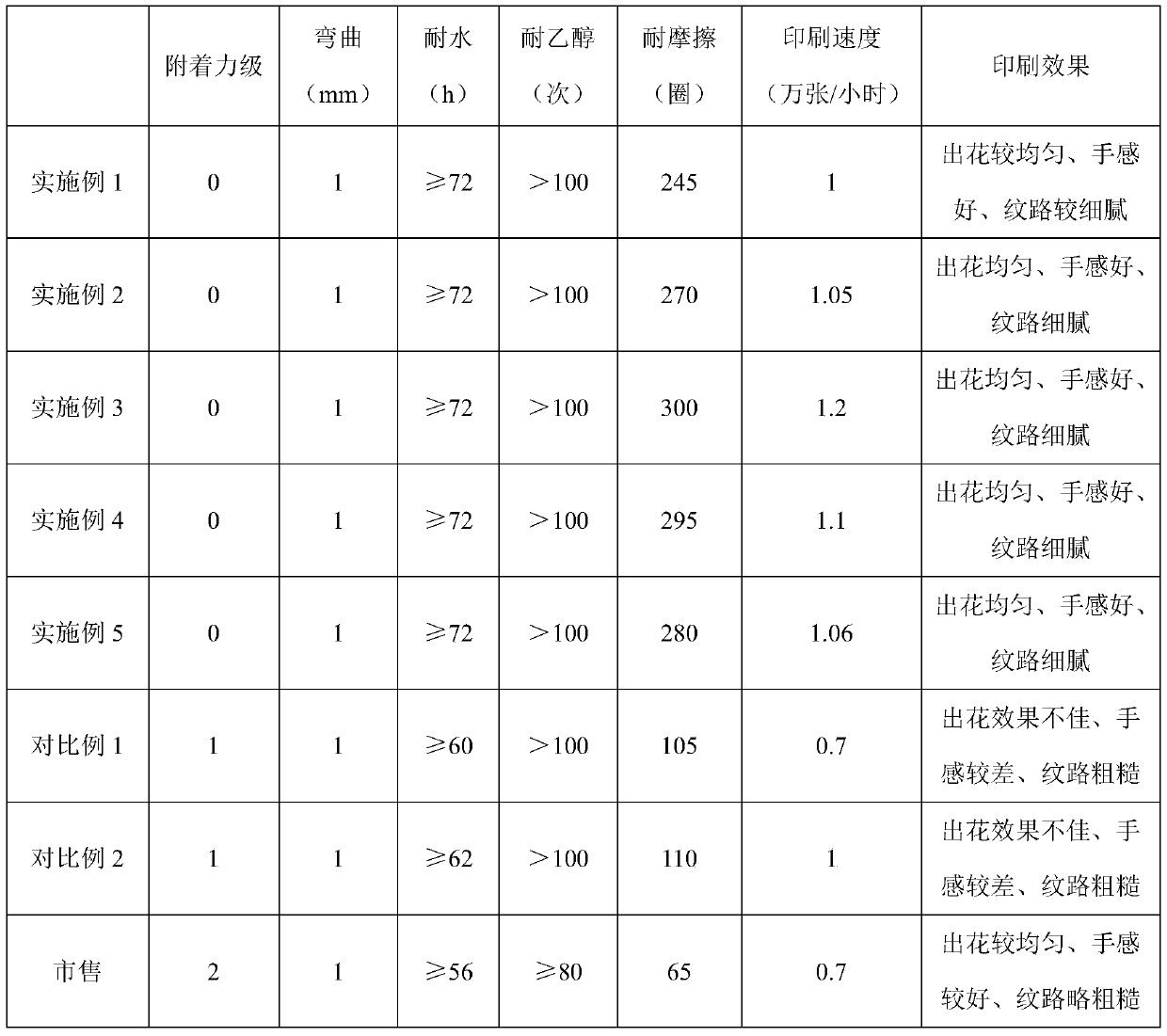

Examples

Embodiment 1

[0034] The UV snowflake printing ink of present embodiment comprises the component of following parts by weight: 25 parts of dipropylene glycol diacrylates, 20 parts of tripropylene glycol diacrylates, 25 parts of polyurethane acrylates, 15 parts of polyketone resins, benzophenone 2.5 parts of derivatives, 0.5 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 0.01 parts of stabilizer, 0.05 parts of defoamer, 0.15 parts of leveling agent and 7 parts of co-initiator.

[0035] A benzophenone derivative is 2-methylbenzophenone.

[0036] The stabilizer is methoxyphenol. The defoamer is polydimethylsiloxane.

[0037] The leveling agent is Tego 432 leveling agent.

[0038] Co-initiator is reactive amine P115.

Embodiment 2

[0040] The UV snowflake printing ink of present embodiment comprises the component of following parts by weight: 43 parts of dipropylene glycol diacrylates, 20 parts of polyurethane acrylates, 20 parts of polyketone resins, 3 parts of benzophenone derivatives, 2,4,6 - 1 part of trimethylbenzoyl-diphenylphosphine oxide, 0.8 parts of stabilizer, 0.4 parts of defoamer, 2.6 parts of leveling agent and 17 parts of co-initiator.

[0041] Benzophenone derivatives are 2-methylbenzophenone and 4-methylbenzophenone, and the mass ratio of 2-methylbenzophenone and 4-methylbenzophenone is 1:1.

[0042] The stabilizer is 4-hydroxy-2,2,6,6-tetramethylpiperidine nitroxide radical.

[0043] The defoamer is defoamer 6800.

[0044] Co-initiator is reactive amine P115.

[0045]The leveling agent is DC27 leveling agent, Digo 432 leveling agent and Digo 450 leveling agent, the weight content of DC27 leveling agent, Digo 432 leveling agent and Digo 450 leveling agent in UV snowflake ink They are:...

Embodiment 3

[0047] The UV snowflake ink of the present embodiment includes the components of the following parts by weight: 50 parts of dipropylene glycol diacrylate, 18 parts of polyurethane acrylate, 12 parts of polyketone resin, 4 parts of benzophenone derivatives, 2,4,6 - 1 part of trimethylbenzoyl-diphenylphosphine oxide, 0.05 part of stabilizer, 0.1 part of defoamer, 1.6 parts of leveling agent and 13 parts of co-initiator.

[0048] Benzophenone derivatives are 3-methylbenzophenone and 4-chlorobenzophenone, and the mass ratio of 3-methylbenzophenone and 4-chlorobenzophenone is 1:2.

[0049] The stabilizer is 4-hydroxy-2,2,6,6-tetramethylpiperidine nitroxide radical.

[0050] The defoamer is defoamer 6800.

[0051] Co-initiator is reactive amine P115.

[0052] The leveling agent is Digo 432 leveling agent and Digo 450 leveling agent, and the weight content of Digo 432 leveling agent and Digo 450 leveling agent in UV snowflake ink is respectively: Digo 432 leveling agent 0.6 1 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com