Anti-cracking UV spray coating white gloss varnish and preparation method of same

An anti-cracking, white topcoat technology, applied in coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems that affect the visual perception and durability of wooden furniture, yellowing, and easy cracking of paint films. Achieve excellent anti-cracking effect, good yellowing resistance and high curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

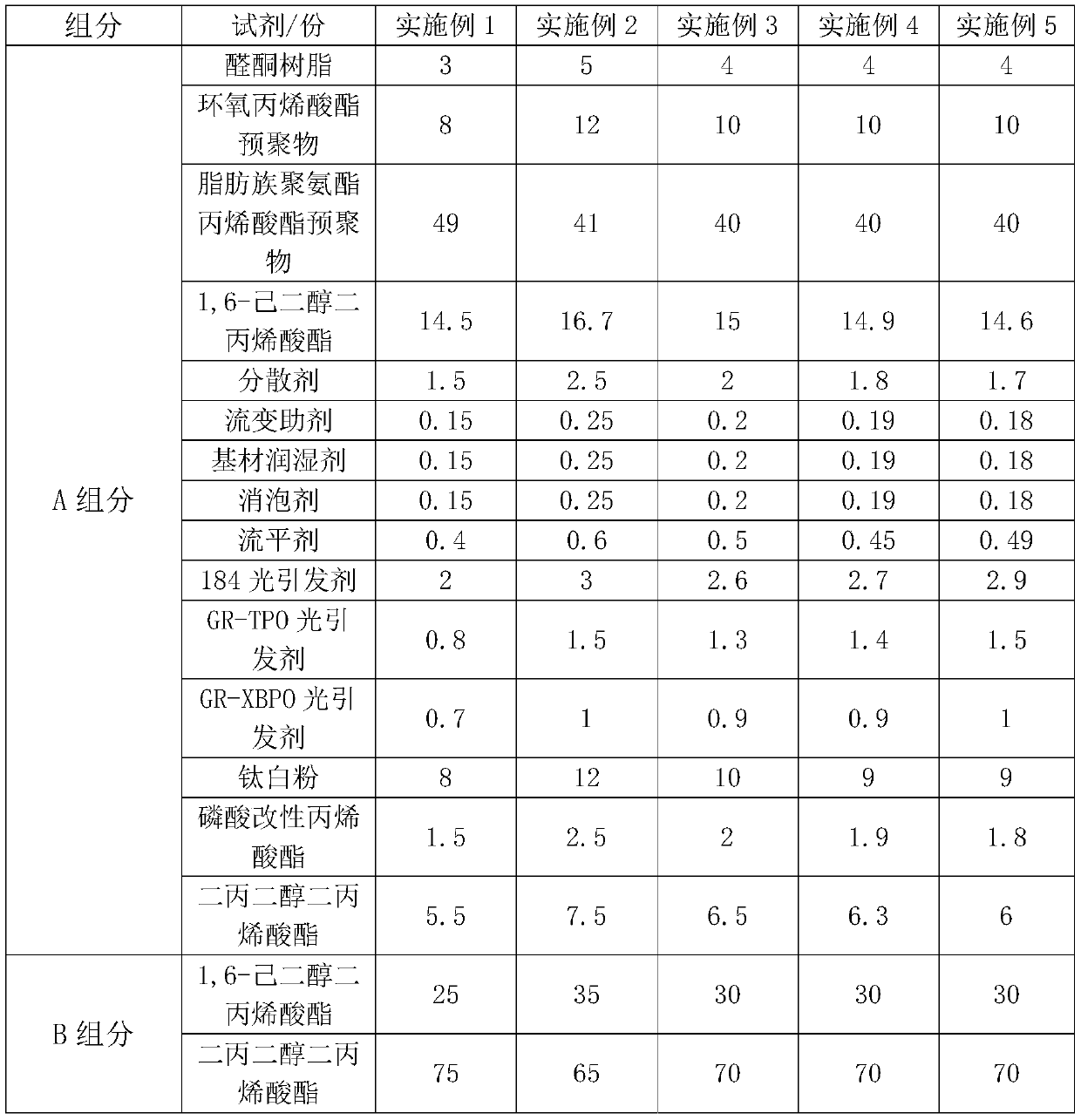

[0056] A kind of anti-cracking UV spraying bright white topcoat, it is prepared by following method:

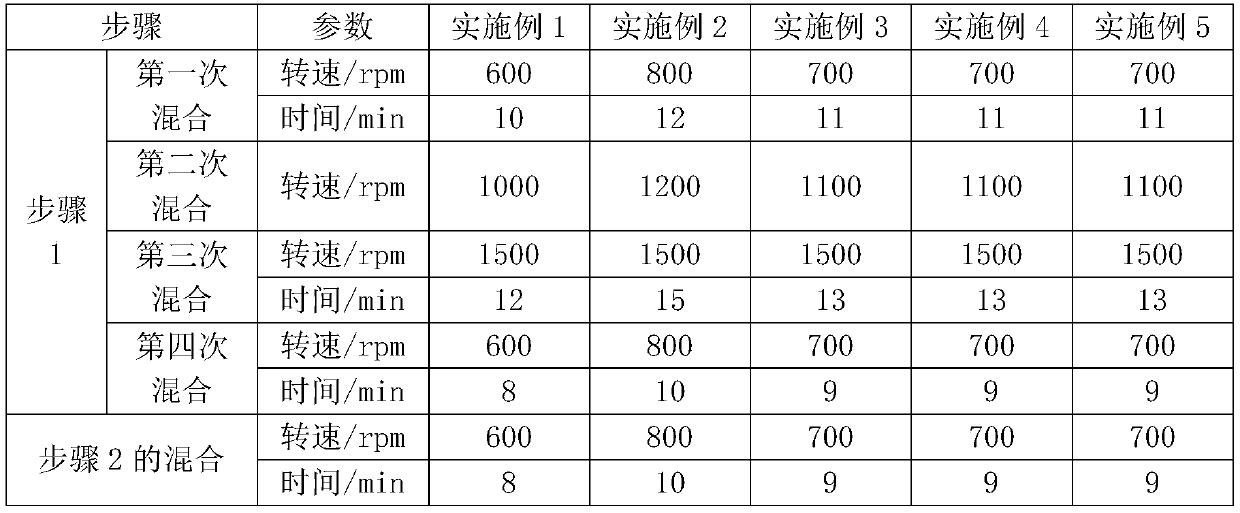

[0057](1) Preparation of component A: Mix aldehyde and ketone resin, epoxy acrylate prepolymer, aliphatic urethane acrylate prepolymer and part of 1,6-hexanediol diacrylate for the first time, then add Dispersant, rheology additive, substrate wetting agent, defoamer, leveling agent, photoinitiator, mixed for the second time, then add titanium dioxide and the remaining 1,6-hexanediol diacrylate, Mix for the third time, then add phosphoric acid-modified acrylate and dipropylene glycol diacrylate, and mix for the fourth time to obtain component A;

[0058] (2) Preparation of component B: Mix 1,6-hexanediol diacrylate and dipropylene glycol diacrylate evenly to obtain component B;

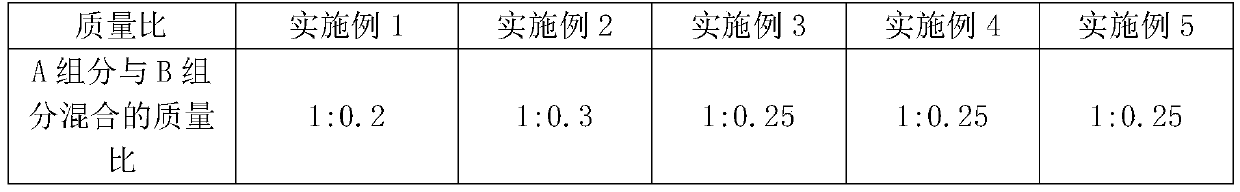

[0059] (3) During construction, the A component and the B component are mixed in a mass ratio of 1: (0.2-0.3) to prepare an anti-cracking UV spray bright white finish paint.

[0060] The third mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com