Low energy- wasting and environment protection method for extracting chitin as well as biologically active substance thereof from shrimp shell

A bioactive substance, chitin technology, applied in food science, organic chemistry, calcium carbonate/strontium/barium, etc., can solve the problems of low product purity, low utilization rate of shrimp shells, high production cost, etc., and achieve good decolorization effect , The effect of thorough digestion of impurities and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

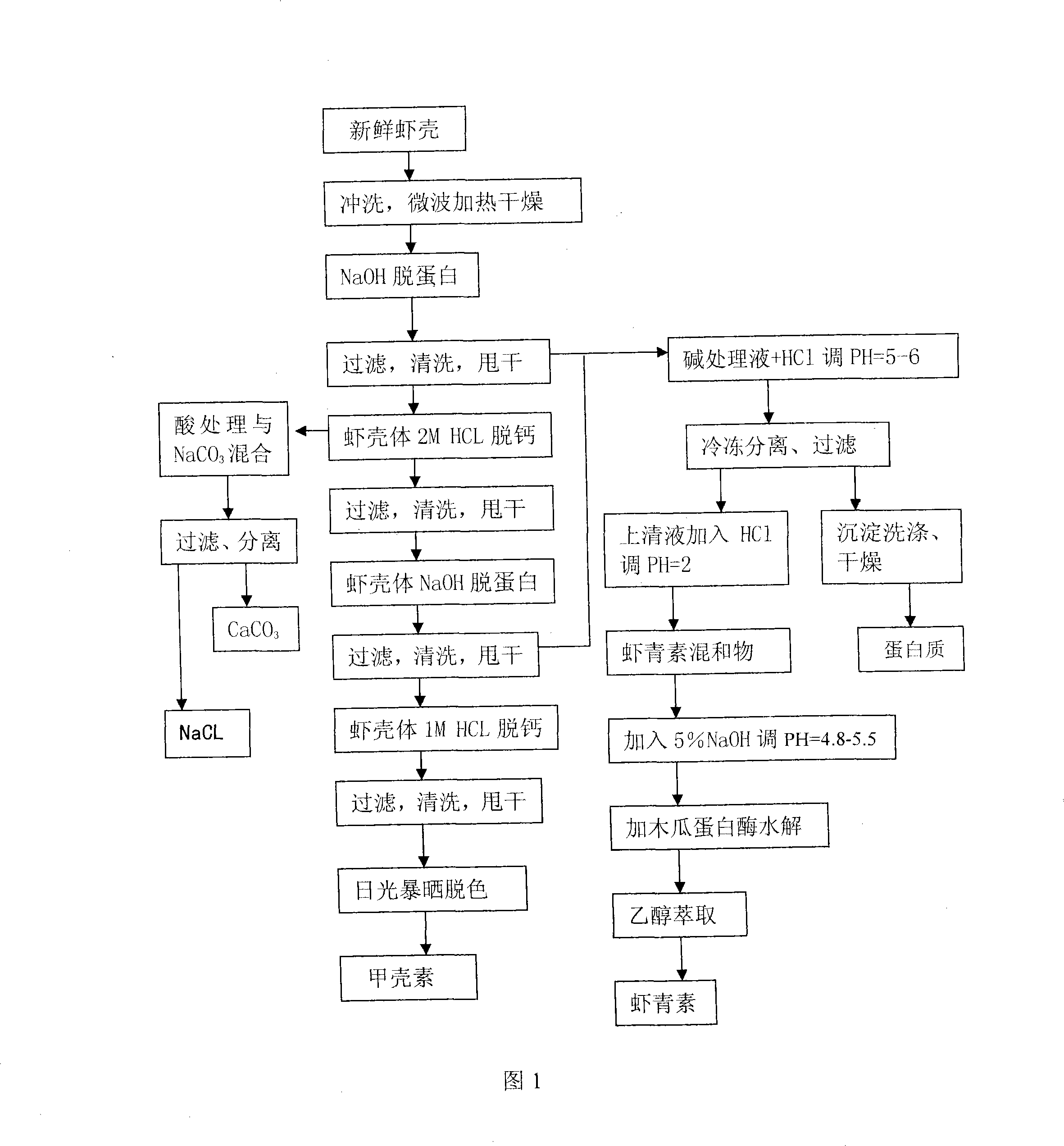

Image

Examples

Embodiment 1

[0023] Example 1: After fresh shrimp shells are washed and drained, they are placed in a microwave oven at a controlled temperature of 80°C. After heating for 10 minutes, the shrimp shells are broken into small pieces, and placed in Boil in 5% NaOH solution for 2 hours, filter to obtain alkali treatment liquid and deproteinized shrimp shells, wash the shrimp shells with clear water until neutral and dry, and the weight ratio of material to liquid is 1:12 Immerse in the ratio of 2mol / LHCl solution and soak for 24 hours, then filter and dry to obtain the acid treatment solution and the decalcified shrimp shell, and the above decalcified shrimp shell is used in a ratio of 1:10 by weight ratio of feed to liquid 5% NaOH solution is processed once again, and the alkali treatment solution and shrimp shells are obtained after filtration, and then the shrimp shells are cleaned and dried, and then placed in a 1mol / L HCL solution in a ratio of 1:12 by weight ratio of material to liquid ,...

Embodiment 2

[0024] Example 2: After fresh shrimp shells are washed and drained, they are placed in a microwave oven at a controlled temperature of 80°C. After heating for 15 minutes, the shrimp shells are broken into small pieces, and placed in Boil in 8% NaOH solution for 2 hours, filter to obtain alkali treatment liquid and deproteinized shrimp shells, wash the shrimp shells with clear water until neutral and dry, and the weight ratio of material to liquid is 1:12 Immerse in the ratio of 2mol / LHCl solution and soak for 24 hours, then filter and dry to obtain the acid treatment solution and the decalcified shrimp shell, the above-mentioned decalcified shrimp shell is used in a ratio of 1:15 by weight ratio of feed to liquid 8% NaOH solution is processed once again, and the alkali treatment solution and shrimp shells are obtained after filtration, and then the shrimp shells are cleaned and dried, and then placed in a 1mol / L HCL solution in a ratio of 1:12 by weight ratio of material to liq...

Embodiment 3

[0025]Example 3: After fresh shrimp shells are washed and drained, they are placed in a microwave oven at a controlled temperature of 80°C. After heating for 12 minutes, the shrimp shells are broken into small pieces, and placed in Boil in 10% NaOH solution for 2 hours, filter to obtain alkali treatment solution and deproteinized shrimp shells, wash the shrimp shells with clear water until neutral and dry them, and use a weight ratio of 1:12 Immerse in the ratio of 2mol / LHCl solution and soak for 24 hours, then filter and dry to obtain the acid treatment solution and the decalcified shrimp shell, the above-mentioned decalcified shrimp shell is used in the ratio of 1:12 by weight ratio of feed to liquid 10% NaOH solution is processed once again, and the alkali treatment solution and shrimp shells are obtained after filtration, and then the shrimp shells are cleaned and dried, and then placed in a 1mol / L HCL solution in a ratio of 1:12 by weight ratio of material to liquid. , fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com