Printing and dyeing waste water treatment process

A kind of printing and dyeing wastewater, treatment process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

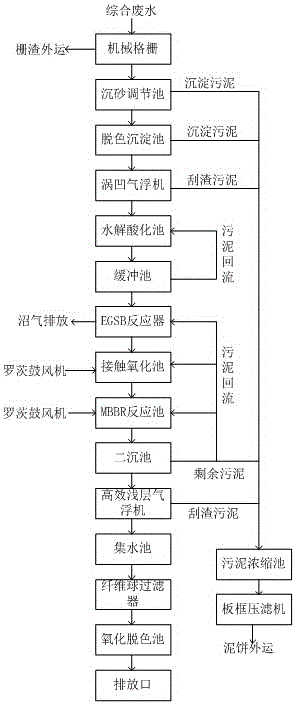

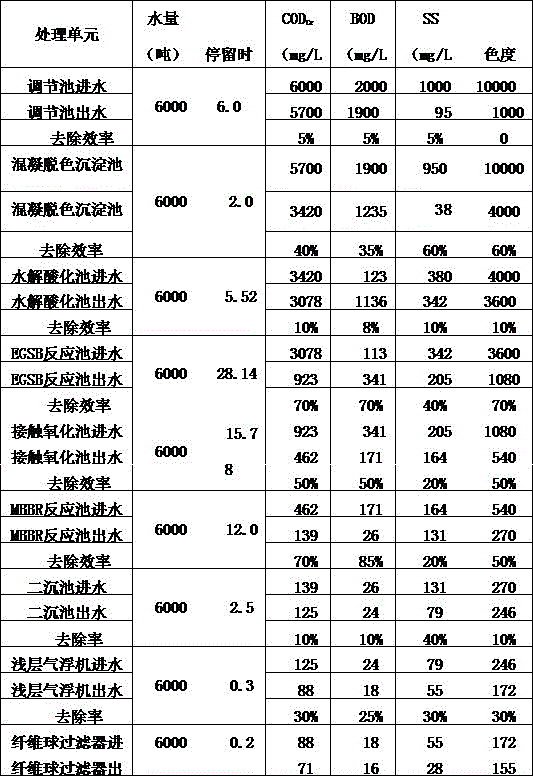

Image

Examples

Embodiment 1

[0076] The composition of the above-mentioned flocculant includes: 8 parts of ferrous sulfate, 6 parts of polyacrylamide, 4 parts of lignosulfonate, 5 parts of alum, 3 parts of polyferric silicon, 6 parts of polyferric sulfate chloride, 3 parts of animal glue, Sodium alginate 5 parts.

Embodiment 2

[0078] The composition of the above-mentioned flocculant includes: 5 parts of ferrous sulfate, 3 parts of polyacrylamide, 2 parts of lignosulfonate, 3 parts of alum, 2 parts of polyferric silicon, 10 parts of polyferric sulfate chloride, 5 parts of animal glue, Sodium alginate 8 parts.

Embodiment 3

[0080] The composition of the above-mentioned flocculant includes: 10 parts of ferrous sulfate, 8 parts of polyacrylamide, 5 parts of lignosulfonate, 7 parts of alum, 5 parts of polyferric silicon, 4 parts of polyferric sulfate chloride, 2 parts of animal glue, Sodium alginate 4 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com