Aluminum-zinc polysilicate composite flocculating agent and application thereof

A technology of polyaluminum zinc silicate and composite flocculant, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problem of reduced decolorization effect of flocculant, complex preparation process, High preparation cost and other problems, to achieve the effect of easy operation, simple preparation method and enhanced sedimentation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of polyaluminum-zinc polysilicate flocculant

[0023] (1) Prepare a 0.4mol / L sodium silicate solution, and dilute concentrated sulfuric acid with a mass fraction of 95% into a 2mol / L dilute sulfuric acid solution;

[0024] (2) Prepare a zinc sulfate solution with a concentration of 0.2mol / L and an aluminum sulfate solution with a concentration of 0.2mol / L;

[0025] (3) Take three 1L beakers, numbered 1-3 in sequence, add 20 mL of 2mol / L dilute sulfuric acid solution, and slowly add 200ml of silicic acid dropwise to the three beakers while stirring the dilute sulfuric acid solution rapidly Sodium solution, adjust the pH of the reaction system to 4 with 2mol / L dilute sulfuric acid solution, then control the stirring speed to 100rpm (in the actual operation process, the stirring speed can be set within the range of 80-120rpm) to carry out the polymerization reaction for 30min, and then The obtained reaction solution was left to stand for activation f...

Embodiment 2

[0029] Prepare a simulated water sample with a turbidity (NTU) of 120. The preparation method is as follows: After passing the kaolin powder through a 180 mesh sieve, put it in an oven for 2 hours at 100°C, and then take an appropriate amount of dry kaolin and add it to tap water under stirring conditions. : Distilled water = 1:1 (volume ratio) water, made into a suspension with an NTU of 120, which is a simulated water sample.

[0030] Under stirring conditions, the polyaluminum-zinc-aluminum-silicate composite flocculant 1-3 obtained in Example 1 was added to the simulated water sample respectively, and the dosage was 5ml / L. First, stir rapidly at a speed of 200 r / min for 40 s. Then stir at a speed of 30 r / min for 30 min, and let it stand for 1 h.

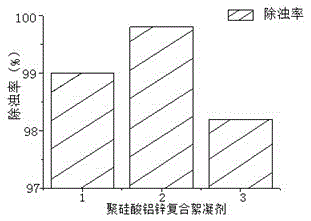

[0031] Take the clear liquid at a distance of 2cm from the liquid surface, and measure the turbidity with a HI 93703-11 turbidimeter, and the obtained results are as follows: figure 1 shown by the attached figure 1 It can be se...

Embodiment 3

[0033] The water quality index of the biochemical effluent from a sewage treatment plant in Zhengzhou is as follows: the COD measured by the potassium dichromate method (GB11914-89) is 62 mg / L, and the total phosphorus concentration measured by the molybdate spectrophotometric method (GB11893-89) is 1.12 mg / L, suspended solids (SS) measured by gravimetric method (GB11901-89) was 18.30 mg / L.

[0034] Take 10 mL of the polyaluminum-zinc composite flocculant 1 prepared in Example 1 in a 2 L beaker, add 1 L of the effluent from the sewage treatment plant, first stir rapidly at a speed of 300 r / min for 30 s, and then Stir at a slow speed of 25 r / min for 40 minutes, and let it stand for 1.5 hours. Measure the clear liquid at a distance of 2 cm from the liquid surface. The test results showed that COD was 16mg / L, total phosphorus was 0.06mg / L, and SS was 0.37 mg / L. It can be seen that the removal rate of COD can reach 74%, the removal rate of total phosphorus can reach 95%, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com