Method for preparing chitosan-like efficient flocculant

The technology of chitosan and flocculant is applied in the field of preparation of chitosan-type high-efficiency flocculant, which can solve the problem of high production cost and achieve the effects of convenient application, remarkable effect and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

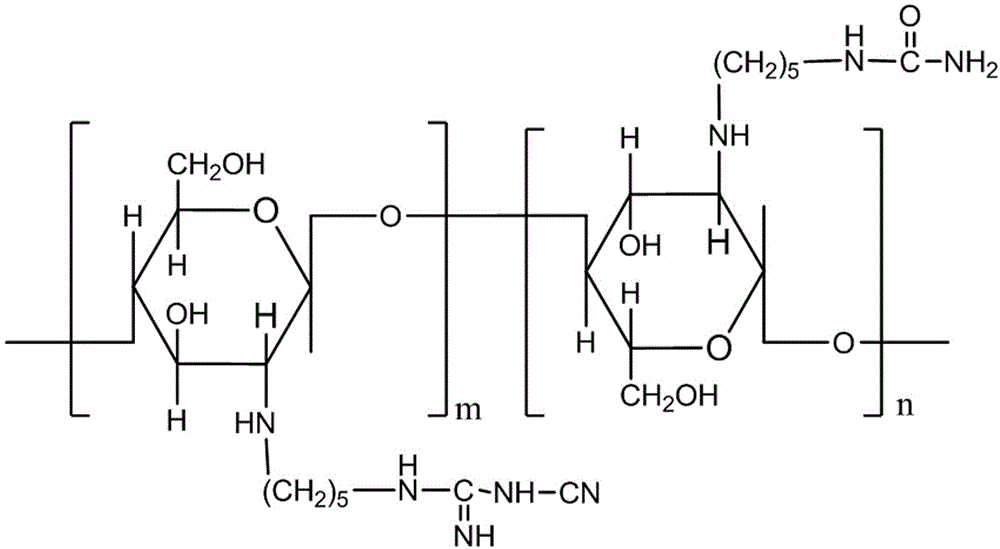

Image

Examples

Embodiment 1

[0020] The preparation method of chitosan-based high-efficiency flocculant includes the following steps in sequence:

[0021] 1) Pretreatment of chitosan: dissolve chitosan in an acetic acid solution of pH=5, stir evenly, add alkali to pH=9 to precipitate the chitosan, and filter for later use;

[0022] 2) Preparation of high-efficiency flocculant: take 1 part of the above chitosan, 3 parts of glutaraldehyde crosslinking agent, 1 part of urea, 1.5 parts of aluminum sulfate and put them in a four-necked flask, stir, and pre-react in a 60℃ water bath. Hours; then add 2.1 parts of dicyandiamide and 0.9 parts of urea, and continue to react for 2 hours to obtain a urea-chitosan-dicyandiamide composite flocculant;

[0023] 3) Purification of the product: After the reaction is completed, the product is separated out with acetone, filtered with suction, then washed with ethanol, filtered with suction and dried in an oven at 90°C for use.

[0024] The printing and dyeing wastewater is treated ...

Embodiment 2

[0028] The preparation method of chitosan-based high-efficiency flocculant includes the following steps in sequence:

[0029] 1) Pretreatment of carboxymethyl chitosan: Dissolve carboxymethyl chitosan in an acetic acid solution with pH=5, stir well, add alkali to pH=9 to precipitate carboxymethyl chitosan, and filter with suction.

[0030] 2) Preparation of high-efficiency flocculant: Take 2 parts of the above carboxymethyl chitosan, 5 parts of glyoxal crosslinking agent, 1 part of urea, 3 parts of aluminum sulfate in a four-necked flask, stir, and preheat in a water bath at 80°C. React for 0.5 hour. Then add 2.4 parts of dicyandiamide and 0.6 parts of urea, and continue to react for 4 hours to obtain a urea-chitosan-dicyandiamide composite flocculant;

[0031] 3) Purification of the product: After the reaction is completed, the product is separated out with acetone, filtered with suction, then washed with ethanol, filtered with suction and dried in an oven at 90°C for use.

[0032] ...

Embodiment 3

[0036] The preparation method of chitosan-based high-efficiency flocculant includes the following steps in sequence:

[0037] 1) Pretreatment of 0-hydroxyethyl chitosan: Dissolve 0-hydroxyethyl chitosan in an acetic acid solution with pH=5, stir evenly, add alkali to pH=9 to polymerize O-hydroxyethyl chitosan The sugar is separated out and filtered with suction.

[0038] 2) Preparation of high-efficiency flocculant: take 1.5 parts of the above-mentioned O-hydroxyethyl chitosan, 4 parts of glutaraldehyde crosslinking agent, 1 part of urea, and 2 parts of aluminum sulfate in a four-necked flask, stir, and in a water bath at 70℃ Pre-reaction for 0.8 hours. Then, 2.4 parts of dicyandiamide and 0.6 parts of urea were added, and the reaction was continued for 3 hours to obtain a urea-chitosan-dicyandiamide composite flocculant;

[0039] 3) Purification of the product: After the reaction is completed, the product is separated out with acetone, filtered with suction, then washed with ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com