A crown ether-based flocculant for papermaking wastewater treatment and preparation method thereof

A technology for papermaking wastewater and flocculant, which is applied in the process of wastewater treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of low flocculation and sedimentation efficiency, secondary pollution, and high drug consumption, and achieves low equipment dependence. , The use of safe and environmental protection, the effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

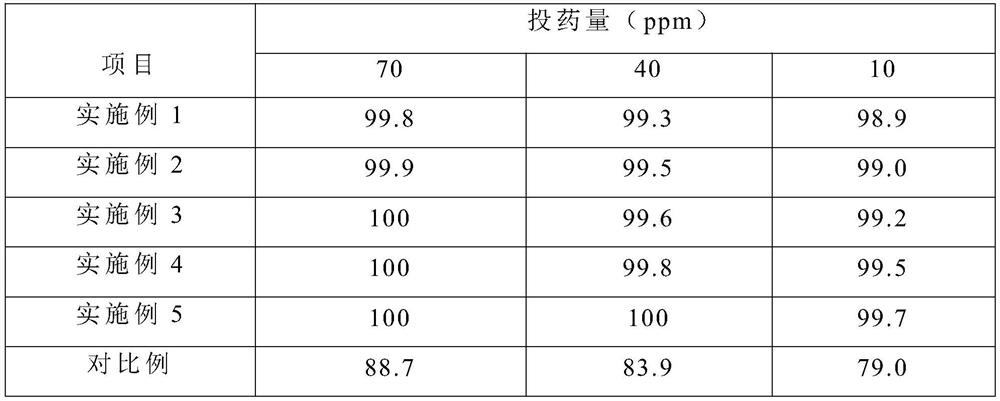

Examples

Embodiment 1

[0032] A method for preparing a flocculant for papermaking wastewater treatment based on crown ether, comprising the steps of:

[0033] Preparation of S1 polymerized betaine: In a three-neck flask equipped with a stirrer, a thermometer, and a constant pressure dropping funnel, add 10 g of 3-trimethoxysilane propyl acrylate, 23.5 g of betaine, 100 g of dichloromethane, and 1g of cuprous metal and 3g of dibutyltin dilaurate, raising the temperature to 85°C, then adding 4g of distilled water dropwise, stirring and reacting at 95°C for 8 hours, then layering, and then rotary evaporation to remove the solvent to obtain polymerized betaine;

[0034] S2 Preparation of crown ether-based acrylamide copolymers: 10 g of polymerized betaine, 4-vinylbenzo-18-crown ether-610 g, 20 g of acrylamide, N-trimethylolform Dissolve 10 g of acrylamide and 1 g of azobisisobutyronitrile in 150 g of dimethyl sulfoxide, stir and react at 65 °C for 4 hours under a nitrogen atmosphere, then precipitate in...

Embodiment 2

[0039] A method for preparing a flocculant for papermaking wastewater treatment based on crown ether, comprising the steps of:

[0040] Preparation of S1 polymerized betaine: In a three-neck flask equipped with a stirrer, a thermometer, and a constant pressure dropping funnel, add 10 g of 3-trimethoxysilane propyl acrylate, 23.5 g of betaine, 110 g of acetonitrile, and ferric chloride 1.3g and 3g of dibutyltin dilaurate, raise the temperature to 87°C, add 4g of distilled water dropwise, stir and react at 96°C for 8.5 hours, then separate layers, and then spin evaporate to remove the solvent to obtain polymerized betaine;

[0041] S2 Preparation of crown ether-based acrylamide copolymers: 10 g of polymerized betaine, 4-vinylbenzo-18-crown ether-610 g, 20 g of acrylamide, N-trimethylolform Dissolve 10g of acrylamide and 1.5g of azobisisobutyronitrile in 162g of N,N-dimethylformamide, stir and react at 67°C for 4.5 hours under a helium atmosphere, then precipitate in acetone, fil...

Embodiment 3

[0046] A method for preparing a flocculant for papermaking wastewater treatment based on crown ether, comprising the steps of:

[0047] Preparation of S1 polymerized betaine: In a three-neck flask equipped with a stirrer, a thermometer, and a constant pressure dropping funnel, add 10 g of 3-trimethoxysilane propyl acrylate, 23.5 g of betaine, 135 g of acetone, and 1.5 g of sodium sulfate and 3g of dibutyltin dilaurate, raise the temperature to 89°C, add dropwise 4g of distilled water, stir and react at 97°C for 9 hours, then separate layers, and then spin evaporate to remove the solvent to obtain polymerized betaine;

[0048] S2 Preparation of crown ether-based acrylamide copolymers: 10 g of polymerized betaine, 4-vinylbenzo-18-crown ether-610 g, 20 g of acrylamide, N-trimethylolform Dissolve 10g of acrylamide and 2g of azobisisobutyronitrile in 175g of N-methylpyrrolidone, stir and react at 69°C for 5 hours under a neon atmosphere, then precipitate in acetone, filter with suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com