Decoloring carclazyte produced from ledikite and turface mixed layer clay as well as production method and application of decoloring carclazyte

A technology for smeared clay and decolorized clay, applied in the field of decolorized clay, can solve the problems of high product cost, increased investment in manpower, material resources and financial resources, complicated production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Crush the raw clay of the Iraqi / smectite layer until the average particle size is less than 20 mesh, dry it at 100°C for 1 hour, and then grind it to 200 mesh to obtain dry-process decolorized clay powder (moisture content less than 1%).

Embodiment 2

[0021] Dry at 80° C. for 3 hours, and the others are basically the same as in Example 1.

Embodiment 3

[0023] Dry at 300° C. for 0.5 hour, and the others are basically the same as in Example 1.

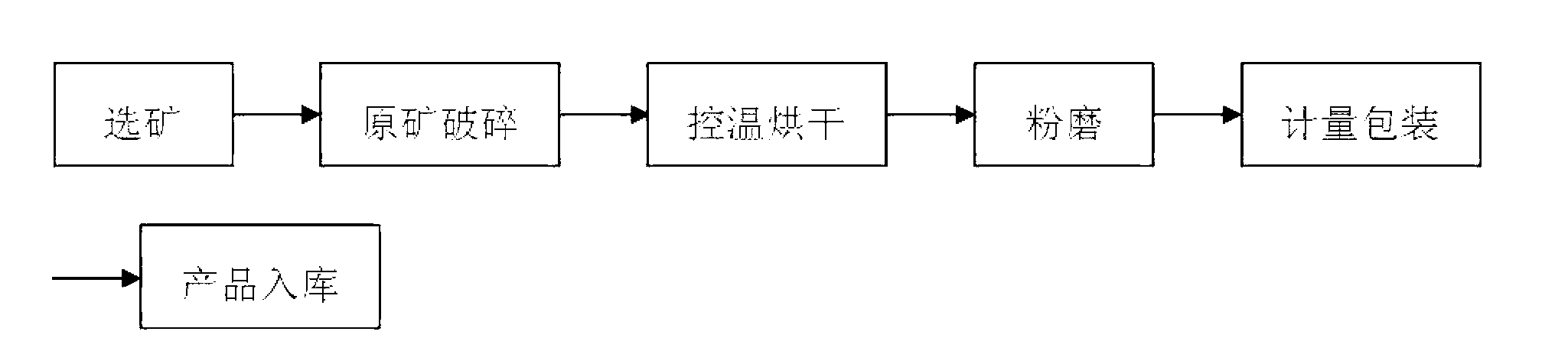

[0024] Such as figure 1 As shown, embodiments 1 to 3 adopt a dry process, the key of which is to control the drying temperature and the particle size of the grinding powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com