Advanced treating method of landfill leachate

A technology for landfill leachate and advanced treatment, applied in the field of advanced treatment, can solve problems such as environmental pollution, advanced treatment process has not yet been reported, etc., achieves good sensory effects, saves pH adjustment operations, and reduces costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

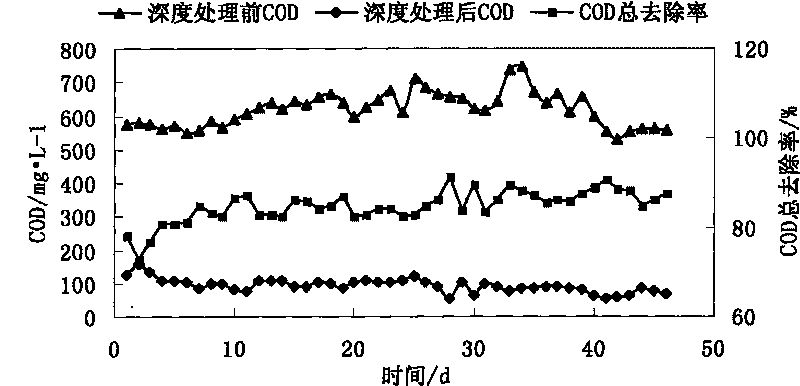

Image

Examples

Embodiment 1

[0042] The advanced treatment process of landfill leachate includes the following steps and process conditions:

[0043] (1) Polyferric coagulation treatment: when the landfill leachate is pumped into the polyferric reaction sedimentation tank through the regulating tank, polyferric (FeSO 4 ·7H 2 O) Amount 0.45mL·L -1 , carry out poly-iron coagulation treatment;

[0044] (2) Fenton oxidation treatment: After polyferric coagulation, the supernatant flows into the Fenton oxidation pool, and FeSO is added to the water inlet 4 and H 2 o 2 The medicine, the medicine is: [Fe 2+ ] is 0.06mol L -1 ,[H 2 o 2 ] is 0.06mol L -1 , the reaction time is 3.5h;

[0045] (3) Neutralization and precipitation: After the wastewater is oxidized by Fenton, it flows into the neutralization tank, and the pH is adjusted to 6-8; after the wastewater is neutralized, synthetic polyacrylamide (RAM) is added to coagulate and precipitate in the sedimentation tank, and the waste water to be treated...

Embodiment 2

[0052] The advanced treatment process of landfill leachate includes the following steps and process conditions:

[0053] (1) Polyferric coagulation treatment: when the landfill leachate is pumped into the polyferric reaction sedimentation tank through the regulating tank, polyferric (FeSO 4 ·7H 2 O) Amount 0.35mL·L -1 , carry out poly-iron coagulation treatment;

[0054] (2) Fenton oxidation treatment: After polyferric coagulation, the supernatant flows into the Fenton oxidation pool, and FeSO is added to the water inlet 4 and H 2 o 2 The medicine, the medicine is: [Fe 2+ ] is 0.10mol L -1 ,[H 2 o 2 ] is 0.10mol L -1 , the reaction time is 3.6h;

[0055] (3) Neutralization and precipitation: After the wastewater is oxidized by Fenton, it flows into the neutralization tank, and the pH is adjusted to 6-8; after the wastewater is neutralized, synthetic polyacrylamide (PAM) is added to coagulate and precipitate in the sedimentation tank, and the waste water to be treated...

Embodiment 3

[0062] The advanced treatment process of landfill leachate includes the following steps and process conditions:

[0063] (1) Polyferric coagulation treatment: when the landfill leachate is pumped into the polyferric reaction sedimentation tank through the regulating tank, polyferric (FeSO 4 ·7H 2 O) Amount 0.30mL·L -1 , carry out poly-iron coagulation treatment;

[0064] (2) Fenton oxidation treatment: After polyferric coagulation, the supernatant flows into the Fenton oxidation pool, and FeSO is added to the water inlet 4 and H 2 o 2 The medicine, the medicine is: [Fe 2+ ] is 0.12mol L -1 ,[H 2 o 2 ] is 0.12mol L -1 , the reaction time is 3.9h;

[0065] (3) Neutralization and precipitation: After the wastewater is oxidized by Fenton, it flows into the neutralization tank, and the pH is adjusted to 6-7.5; after the wastewater is neutralized, synthetic polyacrylamide (PAM) is added to coagulate and precipitate in the sedimentation tank, and the waste water to be treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com