Novel fuel cell manufacturing method based on graphene thermoelectric management layer

A fuel cell and management technology, applied in the direction of fuel cells, fuel cell additives, battery electrodes, etc., can solve the problems of fuel cell cost and durability, lack of low cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

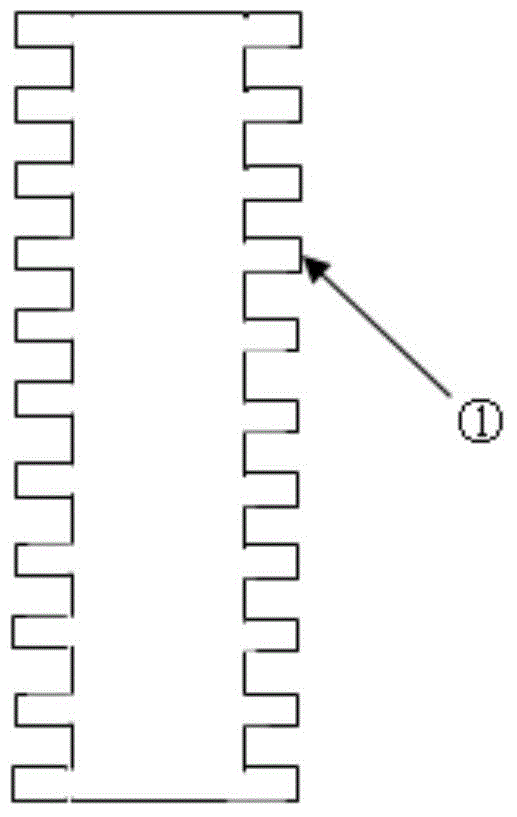

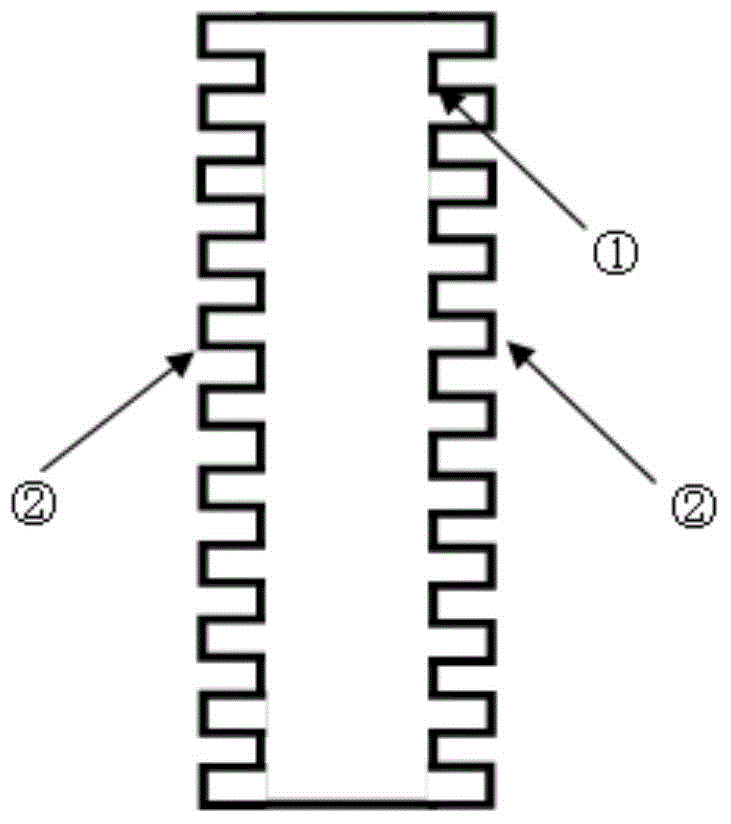

[0044] Use a proton exchange membrane (perfluorosulfonic acid type) with a thickness of 20 microns, and use an embossing template with striped protrusions (the striped protrusion is 10 microns) at 130°C to hot-press the concave and convex on both sides of the proton exchange membrane. microstructure. A proton exchange membrane with ordered microstructures on both sides was prepared. Then, the above-mentioned proton exchange membrane is put into the atomic layer vapor deposition equipment, and the precursor of Pt, MeCpPtMe3, is passed through first, and after several cycles, the precursor that reaches the atomic level is chemically adsorbed on the surface of the above-mentioned proton exchange membrane. After the excess precursor is discharged, the Pt thin film layer is prepared by passing through hydrogen plasma for reduction, and a three-in-one assembly of catalytic layer thin film | proton exchange membrane | catalytic layer thin film is made. Observed under an electron mic...

Embodiment 2

[0047] Use a proton exchange membrane (aromatic ring type) with a thickness of 50 microns, and use an embossing template with striped protrusions (0.5 microns for striped protrusions) at 155°C to heat-press concave and convex ordered microstructures on both sides of the proton exchange membrane . A proton exchange membrane with ordered microstructures on both sides was prepared. Then, immerse the above-mentioned proton exchange membrane in H2PtCl6 solution, add formaldehyde solution after immersion for 5 hours to reduce to obtain Pt particles, prepare Pt thin film layers on both sides of the above-mentioned proton exchange membrane, and make a catalytic layer thin film|proton exchange membrane|catalyst layer Membrane 3-in-1 component. Observed under an electron microscope, the main particle size distribution of the Pt catalyst particles is 10 nanometers, the catalyst particles are evenly attached to the surface of the proton exchange membrane, and each catalyst particle is cl...

Embodiment 3

[0050] Use a reinforced perfluorosulfonic acid proton exchange membrane with a thickness of 18 microns, and use an embossing template with striped protrusions (the striped protrusions are 1 micron) at 130°C to heat-press the concave-convex orderly microstructures on both sides of the proton exchange membrane. structure. A proton exchange membrane with ordered microstructures on both sides was prepared. Then, immerse the above-mentioned proton exchange membrane in a mixed solution of H2PtCl6 and RuCl3, add formic acid solution after immersion for 2 hours to obtain PtRu alloy particles, and prepare PtRu thin film layers on both sides of the above-mentioned proton exchange membrane to make a catalytic layer thin film|proton exchange Membrane|Catalytic layer thin film three-in-one component. Observed under the electron microscope, the main particle size distribution of the PtRu alloy catalyst particles is 5 nanometers, the catalyst particles are evenly attached to the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com