Wave isolation type wave energy generator

A generator and wave isolation technology, which is applied in the directions of ocean energy power generation, hydropower generation, engine components, etc., can solve the problems of poor wave energy efficiency, difficult production, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further described below in conjunction with accompanying drawing:

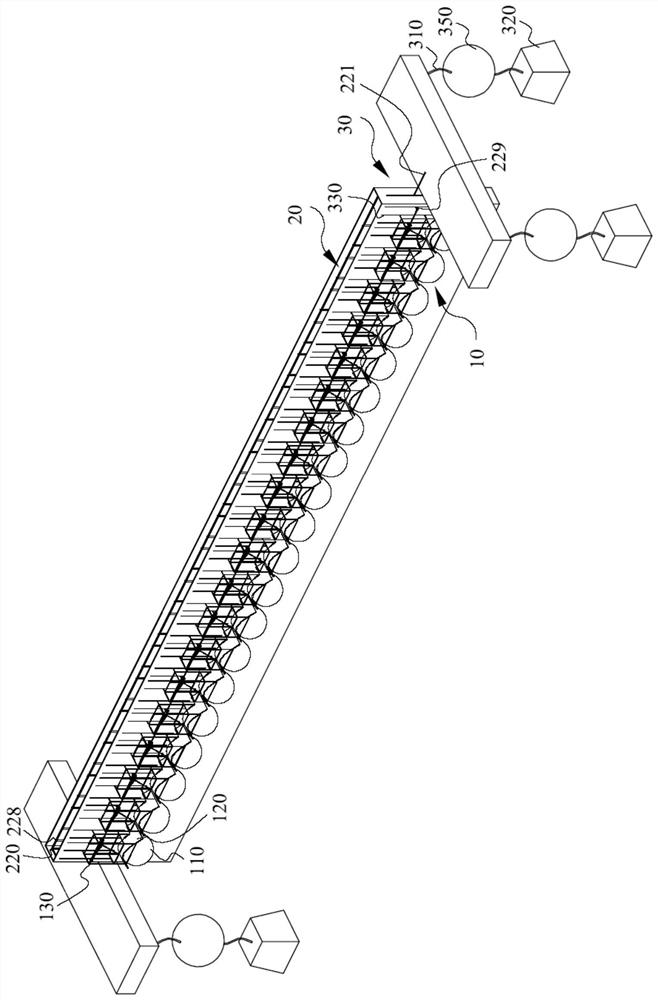

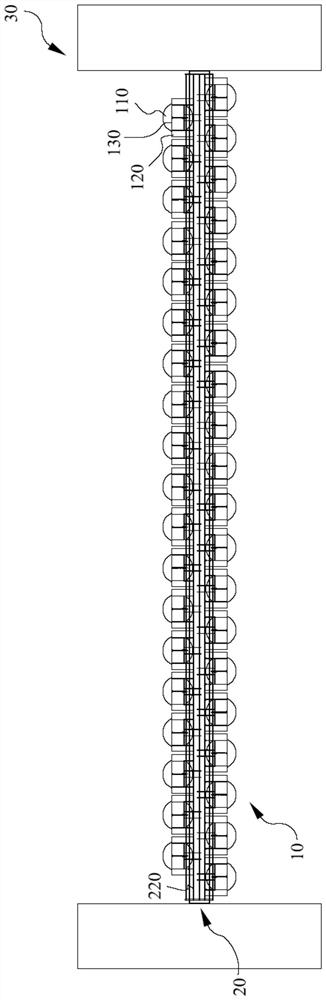

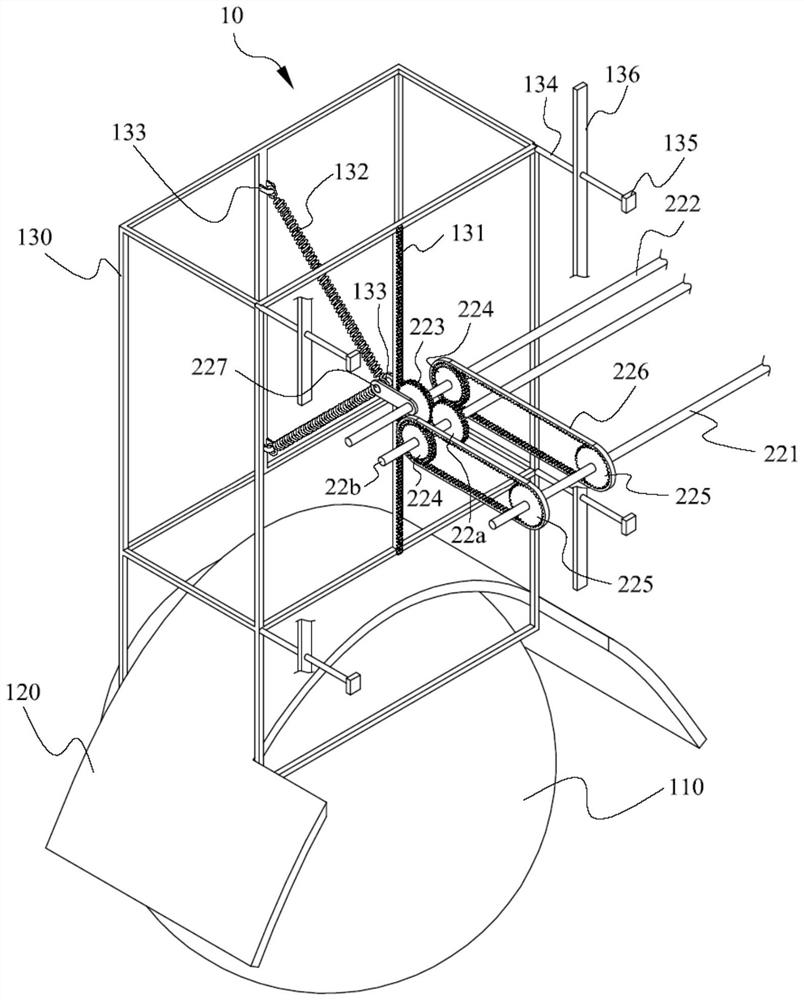

[0046] see Figures 1 to 15 As shown, the basic structure of the present invention is a wave energy generator, which is composed of multiple groups of buoyant ball units 10 , a group of floating tank platform units 20 and a group of clapboard units 30 .

[0047]The pontoon platform unit 20 has a large pontoon 210, and a support frame 220 is erected above the pontoon 210, and the support frame 220 is pushed on the sea surface by using the pontoon 210; the support frame 220 is provided with a central rotating shaft 221, and the center An outer rotating shaft 222 is arranged on both sides of the rotating shaft 221, and a plurality of power gears 223 are arranged on the outer rotating shaft 222. Each power gear 223 corresponds to a group of float units 10 and a ratchet 224 is arranged on the right side thereof. A driven gear 225 is arranged on the central rotating shaft 221, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com