Aluminum doped nano-zinc oxide coated NCA positive material and preparation method thereof

A technology of nano-zinc oxide and nickel-cobalt-lithium aluminate, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor thermal stability and storage performance, and restrict development and application. Achieve the effects of improving electronic conductivity, preventing damage, and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

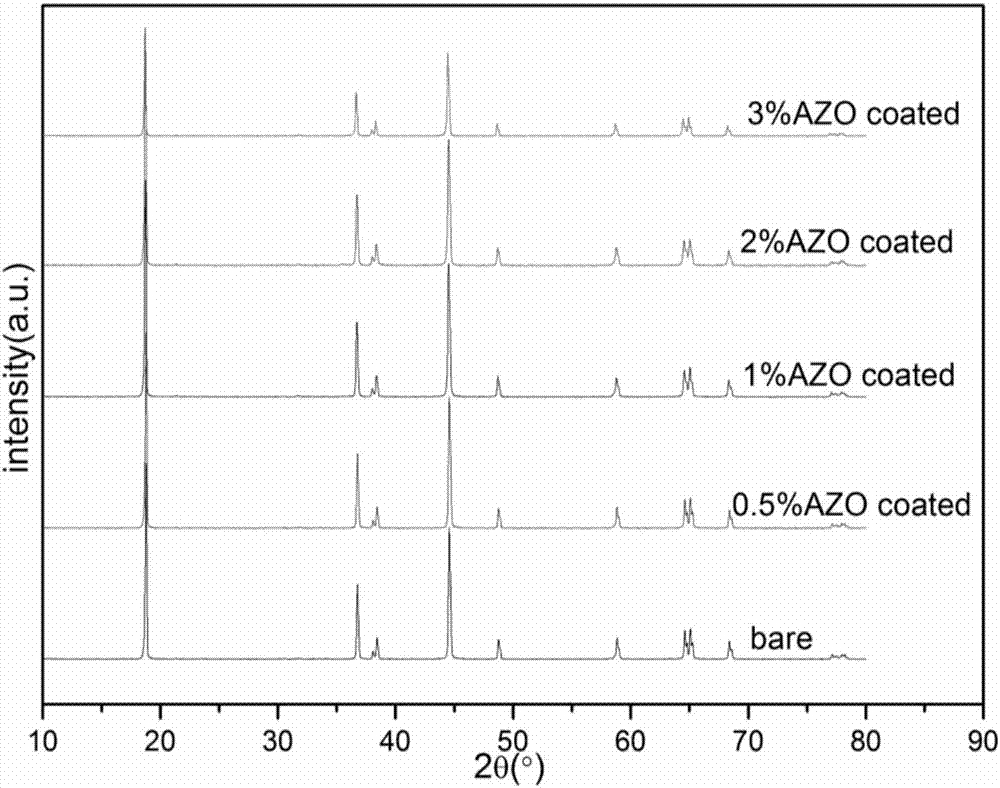

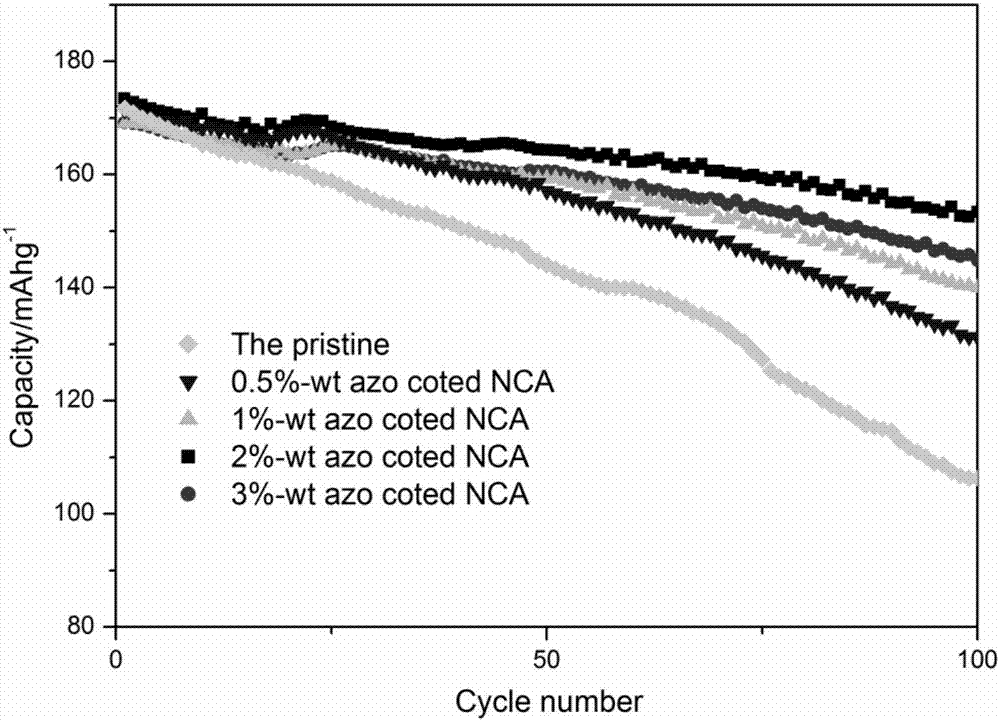

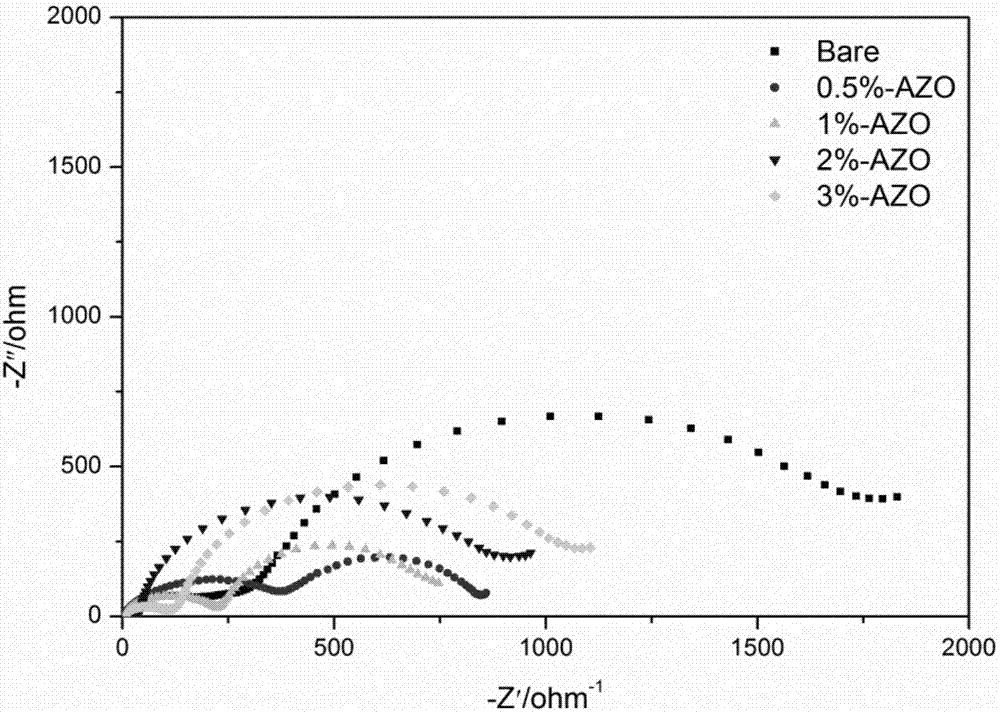

[0026] Take a certain amount of zinc acetate dihydrate and add it to a 100ml beaker, add 30ml of absolute ethanol, then add ethanolamine in an equimolar ratio to zinc acetate and stir to dissolve the zinc acetate to form a uniform solution (solution A). Add aluminum nitrate nonahydrate to the solution in a molar ratio of 1:0.02 to zinc acetate, and stir for 1 hour to mix the solution evenly (solution B). Calculated on the basis that the aluminum-doped ZnO cladding layer accounts for 0.5%, 1%, 2%, and 3% of the product mass content, add nickel-cobalt lithium aluminate materials to the solution, and transfer the beaker to an oil bath at 80°C to keep the temperature Stir for 5h.

[0027] Transfer the obtained sol to a blast drying oven at 120°C for aging for 48 hours to obtain a gel, pre-fire the obtained gel at a constant temperature of 300°C for 3 hours in an oxygen atmosphere, bake at 600°C for 5 hours, cool naturally, and grind to obtain a coating finished product.

[0028]...

Embodiment 2

[0033]Get a certain amount of zinc sulfate heptahydrate and add in the 100ml beaker, add 30ml dehydrated alcohol, then add the ethanolamine that is 1:2 with zinc sulfate heptahydrate mol ratio and vigorously stir to make zinc sulfate heptahydrate dissolve and form a uniform solution (solution A). Add aluminum sulfate octahydrate to the solution with a molar ratio of 1:0.04 to zinc sulfate heptahydrate, and stir for 1 hour to mix the solution evenly (solution B). Assuming that the ZnO coating mass ratio is 2%, nickel-cobalt-lithium-aluminate material is added to the solution, and the beaker is transferred to an oil bath at 80° C. and stirred at constant temperature for 5 hours.

[0034] Transfer the obtained sol to a blast drying oven at 120°C for aging for 48 hours to obtain a gel, pre-fire the obtained gel at a constant temperature of 400°C for 2 hours in an oxygen atmosphere, bake at 650°C for 8 hours, and then cool naturally and grind to obtain a coating The amount is 2% o...

Embodiment 3

[0039] Take a certain amount of zinc acetate dihydrate and add it to a 100ml beaker, add 30ml of ethylene glycol, and then add diethanolamine with a molar ratio of 1:3 to zinc acetate and stir vigorously to dissolve the zinc acetate to form a uniform solution (solution A). Add aluminum nitrate nonahydrate to the solution in a molar ratio of 1:0.05 to zinc acetate, and stir for 2 hours to mix the solution evenly (solution B). Assuming that the ZnO coating mass ratio is 2%, nickel-cobalt-lithium-aluminate material is added to the solution, and the beaker is transferred to an oil bath at 80° C. and stirred at constant temperature for 5 hours.

[0040] Transfer the obtained sol to a blast drying oven at 120°C for aging for 48 hours to obtain a gel, pre-fire the obtained gel at a constant temperature of 350°C for 4 hours in an oxygen atmosphere, bake at 550°C for 4 hours, cool naturally, and grind to obtain a coating The amount is 2% of the finished product.

[0041] The positive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com