Method for making lead-acid battery pole plate

A technology for lead-acid battery and manufacturing method, which is applied in the direction of lead-acid battery electrodes, electrode carriers/collectors, etc., can solve the problems of environmental pollution, lead resource consumption, etc., achieve good conductivity, facilitate post-processing of the process, and strong bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Group A: 12V-100Ah lead-acid batteries assembled with traditional battery plates for both positive and negative plates.

[0039] Group B: 12V-100A lead-acid battery assembled with the positive plate and the negative plate of the lead-acid battery prepared by the present invention, respectively.

[0040] The experimental results of the comparison between group A and group B are listed in Table 1:

[0041] Table 1

[0042]

[0043] It can be obtained from this table: the 12V-100Ah battery assembled with the battery plate prepared by the present invention has the same performance as the battery assembled by the traditional battery plate, and the battery weight is only 86% of the weight of the traditional battery, and about 6kg of lead is saved. .

Embodiment 2

[0045] Group A: 2V-600Ah lead-acid batteries assembled with traditional battery plates for both positive and negative plates.

[0046] Group B: 2V-600Ah lead-acid battery assembled with the positive plate and the negative plate of the lead-acid battery prepared by the present invention, respectively.

[0047] The experimental results of the comparison between group A and group B are listed in Table 1:

[0048] Table 2

[0049]

Battery weight (kg)

Battery weight reduction (%)

Battery capacity (Ah)

Group A

41

-

612

Group B

35

15%

615

[0050] It can be obtained from this table that the 2V-600Ah battery assembled with the battery plate prepared by the present invention has the same performance as the battery assembled by the traditional battery plate, and the battery weight is only 85% of the weight of the traditional battery, and about 6kg of lead is saved.

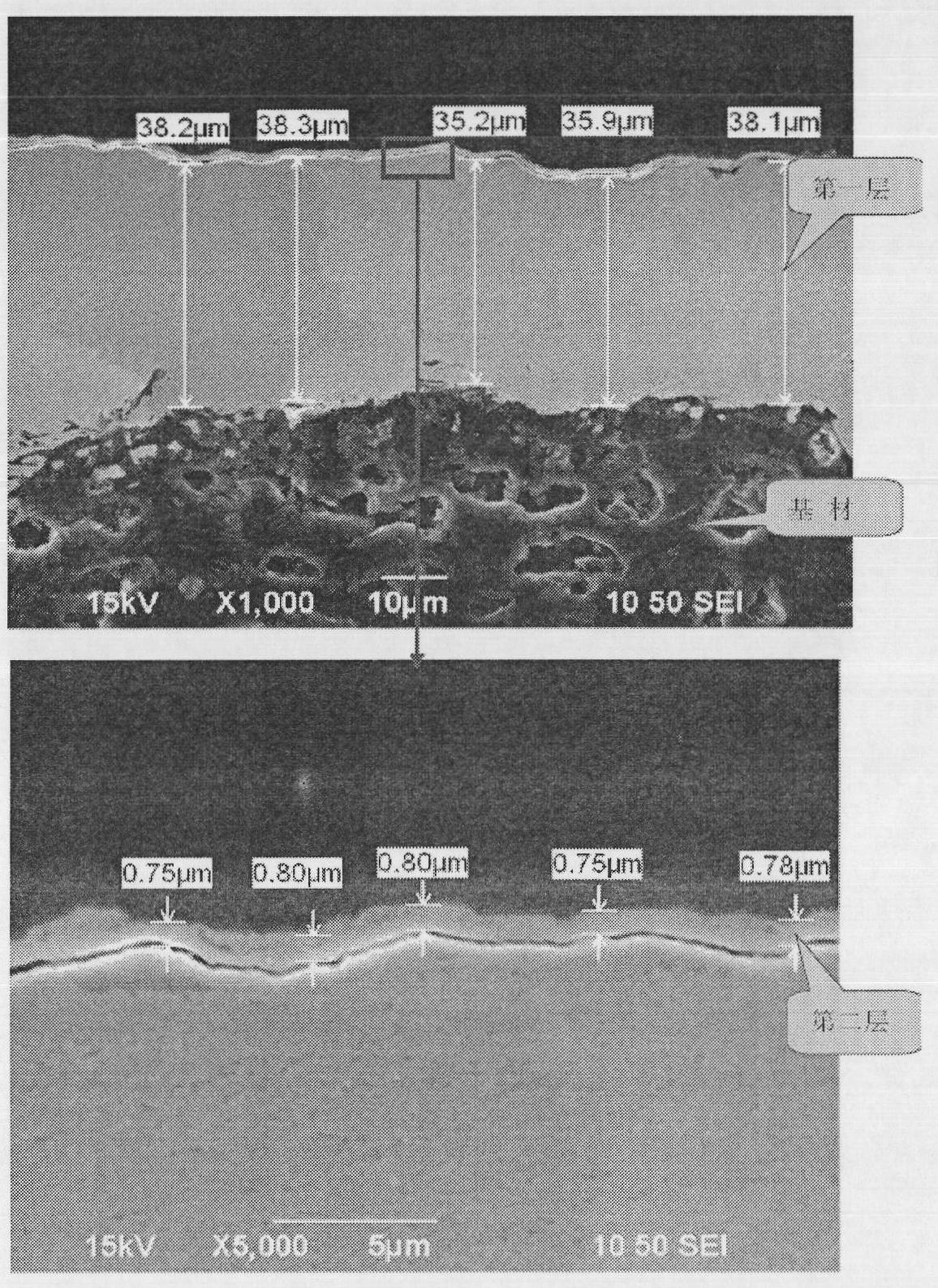

[0051] Figure 9 It is a schematic diagram of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com