Negative electrode of zinc-bromine flow battery for energy storage and manufacture method thereof

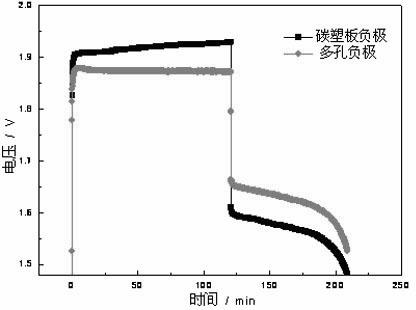

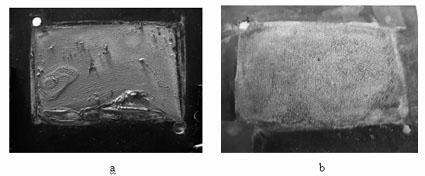

A technology of battery negative electrode and negative electrode, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of large electrochemical polarization of zinc deposition and dissolution, zinc dendrite, small contact area between electrolyte and electrode, etc., and achieves easy operation. , the effect of increasing the contact area and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Porous layer slurry configuration: by weight parts, weigh 1 g of chlorinated polypropylene, 1 g of activated carbon, and 1 g of conductive graphite, and dissolve them with an appropriate amount of ethyl acetate for later use;

[0024] 2) The porous agent slurry is evenly coated on one side surface of the carbon-plastic composite material plate by spraying to prepare a porous layer;

[0025] 3) The carbon-plastic composite material plate coated with the porous agent layer is subjected to vacuum high-temperature drying treatment, the drying temperature is 90°C, the drying time is 60s, the vacuum degree is -0.01MPa, and the temperature is kept at room temperature to obtain the negative electrode. And assemble the battery for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com