Electrical storage device provided with fiber electrodes, and method for producing same

一种蓄电设备、纤维的技术,应用在电解质蓄电池制造、电极制造、二次电池制造等方向,能够解决电池结构不可能实现高输出等问题,达到实现极速充电、加快充电速度和放电速度、增加表面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

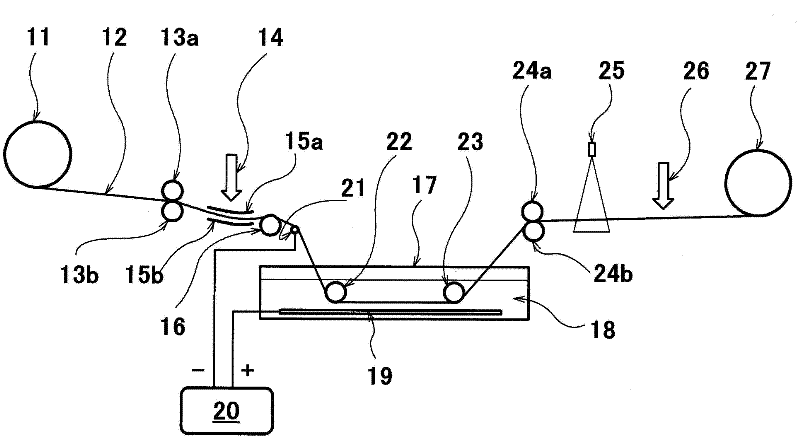

[0170] use figure 2 The shown fiber electrode manufacturing equipment manufactures fiber positive electrodes for lithium-ion secondary batteries. In the production process of the fiber positive electrode (process (A)), two acrylic water tanks were prepared. The first tank is an aluminum plating bath ((AlCl 3 -EMIC) is room temperature molten salt; AlCl 3 The molar ratio to EMIC is 2:1); the second water tank is a manganese nitrate bath (1 mol / liter) for electrolysis of manganese hydroxide.

[0171] First, the PAN-based carbon fiber (diameter 6um) composed of 12,000 fiber bundles wound on the roller is relaxed between two guide rollers, and the air compressed by the air compressor is used to blow it, and the carbon fiber bundle is stretched from the original 1cm. The width is uniformly opened to a width of 6 cm, and immersed in an aluminum plating bath. Lay an aluminum plate with a thickness of 2mm on the bottom of the water tank, and connect it to the positive terminal. ...

Embodiment 2

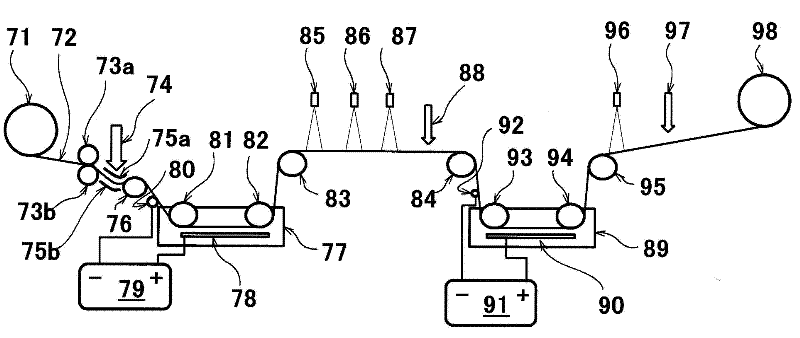

[0180] use with image 3 The same fiber electrode manufacturing equipment uses carbon fiber with a separator coating on the surface as a fiber negative electrode for lithium-ion secondary batteries. The carbon fibers are the same as those used in Example 1. Lithium nitrate (LiNO 3 ) and sodium phosphate (NaH 2 PO 4 ) were dissolved in ion-exchanged water at a ratio of 0.1 mol / L and 0.02 mol / L, respectively, as Li 3 PO 4 Electrolyte for precipitation. Carbon can be used as a negative electrode for lithium-ion batteries, so carbon fiber can be used directly as a fiber negative electrode. Li 3 PO 4 Both insulation and lithium ion conductivity, so covered Li 3 PO 4 The carbon fiber can act as both an isolation layer and an electrolyte. When the fiber is wound, the winding roller is rotated at a speed of 5 cm / min, while the inter-electrode voltage is kept at 7 V, and electrolysis is performed for 10 minutes to deposit Li with a thickness of about 10 μm as the negative el...

Embodiment 3

[0191] use Figure 7 The pressure cutting device shown produces a laminate of a fiber positive electrode and a fiber negative electrode. Insert the fiber anode of embodiment 1 from mold 142, insert the Li 3 PO 4 Film-coated fiber anode. The lengths of the fiber electrodes inserted from the two molds are respectively shorter than L by 3 mm. In this state, by operating the cutting blade, the ends of the fiber positive electrode and the fiber negative electrode inserted from the molds 141 and 142 can be cut off, and the laminated fiber positive electrode and fiber negative electrode can be compressed at the same time, thus obtaining Figure 8 (a) shows a block-shaped fiber electrode laminate 147 .

[0192] Next, if Figure 8 As shown in (b), PP resin 148 is coated on the positive terminal side and the negative terminal side of the fiber electrode laminate 147 , respectively. After the adhesive 148 dries, grind it according to the dotted lines with a grinder, as Figure 8 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com