Fiber electrode and fiber cell, and method for producing same, facility for producing fiber electrode and fiber cell

A fiber electrode and manufacturing method technology, applied in the direction of electrolyte battery manufacturing, electrode manufacturing, secondary battery manufacturing, etc., can solve the problem that the battery structure cannot achieve high output, etc., to achieve ultra-fast charging, increase charging speed and discharge speed , The effect of reducing the internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

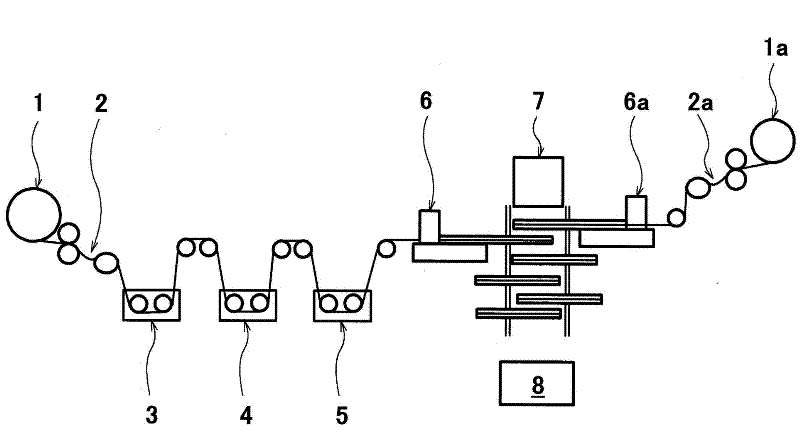

[0128] (1) Fiber battery manufacturing equipment

[0129] figure 1 It is a schematic configuration diagram showing an example of a fiber battery manufacturing facility. figure 1 Reference numeral 1 in the middle indicates a winding roll for winding a fiber bundle of a plurality of polyacrylonitrile (PAN)-based carbon fibers into a roll shape. Reference numeral 2 denotes a fiber-opening device for opening a carbon fiber block formed of a fiber bundle of a plurality of fibers and preparing it for use in the next step. Symbol 3 represents the plating tank; symbol 4 represents the electrolytic tank; symbol 5 represents the alkali tank. Symbol 6 represents a device for forming a separator coating; symbol 7 represents a pressure cutting device for laminating, compression molding and cutting a fiber positive electrode and a fiber negative electrode having a separator coating formed on at least one of them; symbol 8 represents a positive electrode terminal and the negative terminal...

Embodiment 2

[0136] image 3 It is a schematic structural diagram of another example of fiber electrode manufacturing equipment. By using such as image 3 The advanced fiber electrode manufacturing equipment has produced fibrous nickel hydroxide positive electrodes for alkaline secondary batteries. exist image 3 In , reference numeral 31 denotes a winding roll for winding a fiber bundle of 12,000 PAN-based carbon fibers into a roll shape. The fiber bundle of the PAN-based carbon fiber 32 rewound by the winding roller 31 passes the upper and lower paired guide rollers 33a and 33b, and blows the pressurized air 34 compressed by the air compressor (not shown) to open the fiber. The bundle is opened from the original 1cm wide to 5cm wide. Reference numerals 35a and 35b denote diffusers for dispersing pressurized air in the width direction of the carbon fiber bundles. The diffuser plates 35a and 35b have the same function as the diffuser plates 15a and 15b.

[0137] The opened PAN-based ...

Embodiment 3

[0144] Figure 4 It is a schematic structural diagram of another example of fiber electrode manufacturing equipment. can be obtained by using such as Figure 4 Advanced fiber electrode manufacturing equipment to produce fibrous positive electrodes for lithium-ion secondary batteries. exist Figure 4 In , reference numeral 71 denotes a winding roll for winding a fiber bundle of 12,000 PAN-based carbon fibers into a roll shape. The fiber bundle of the PAN carbon fiber 72 rewound by the winding roller 71 passes through the upper and lower paired guide rollers 73a and 73b, and blows the pressurized air 74 compressed by the air compressor (not shown) to it, from the original 1cm wide The fiber opening is 5cm wide. Reference numerals 75a and 75b denote diffusers for dispersing pressurized air in the width direction of the carbon fiber bundles. The diffuser plates 75a and 75b have the same function as the diffuser plates 15a and 15b.

[0145] The opened PAN-based carbon fibers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com