Method for coating nickel cobalt lithium manganate positive-electrode material with calcium fluophosphate

A technology of nickel-cobalt-lithium-manganese-manganese oxide and positive electrode materials, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor battery cycle performance and unstable electrochemical performance, and achieve the effect of inhibiting dissolution and improving capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

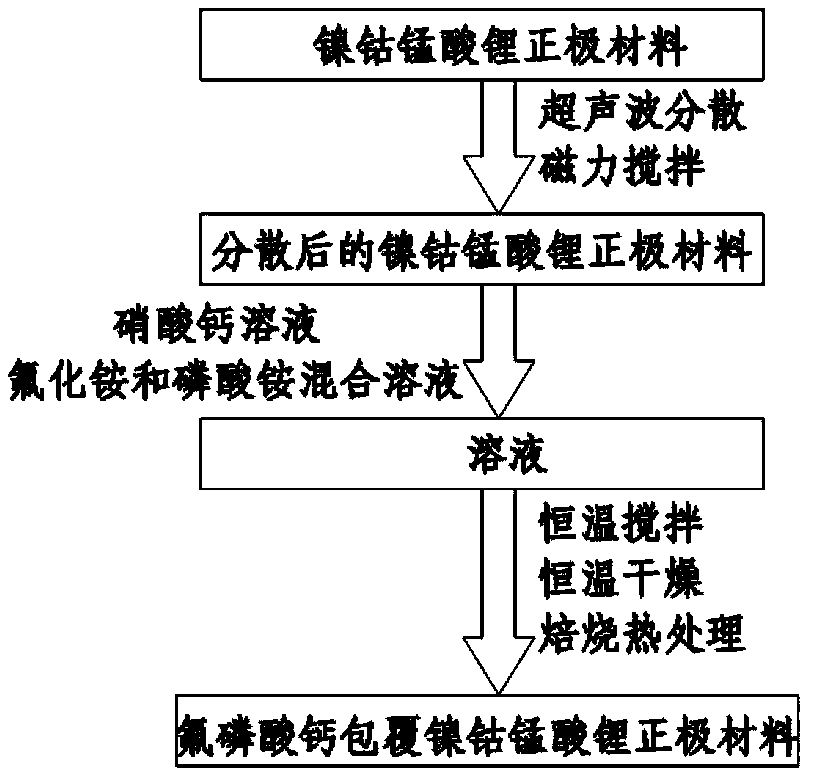

[0036] according to figure 1 The preferred embodiment shown, a method for coating nickel cobalt lithium manganese oxide cathode material with calcium fluorophosphate, comprises the following steps:

[0037] a) Dissolve the nickel-cobalt-lithium-manganese-oxide cathode material in deionized water and disperse for 3-4 hours;

[0038] b) adding calcium nitrate solution to the nickel cobalt lithium manganate positive electrode material dispersed in step a, and then adding ammonium fluoride and ammonium phosphate mixed solution, the calcium nitrate solution and the ammonium fluoride and the phosphoric acid The substance ratio of the ammonium mixed solution is 5:1:3, and the reaction generates calcium fluorophosphate;

[0039] c) Stir the suspension obtained in step b at a constant temperature of 75-85°C for 2-4 hours, evaporate the solvent to dryness, and dry at a constant temperature of 120°C for 12 hours;

[0040] d) putting the dried material in step c into a muffle furnace fo...

Embodiment 2

[0047] Same as Example 1, the difference is:

[0048] The mass ratio of calcium fluorophosphate to nickel cobalt lithium manganese oxide cathode material is 0.02:1.

Embodiment 3

[0050] Same as Example 1, the difference is:

[0051] The mass ratio of calcium fluorophosphate to nickel-cobalt-lithium manganese oxide cathode material is 0.03:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com