Lithium ion secondary battery

A secondary battery and lithium-ion technology, applied in the direction of secondary batteries, secondary battery manufacturing, battery electrodes, etc., can solve the problems of inability to improve conductivity, inability to seek capacity, condensation of conductive materials, etc., and achieve excellent output characteristics, high Potential cycle characteristics, effect of high active material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

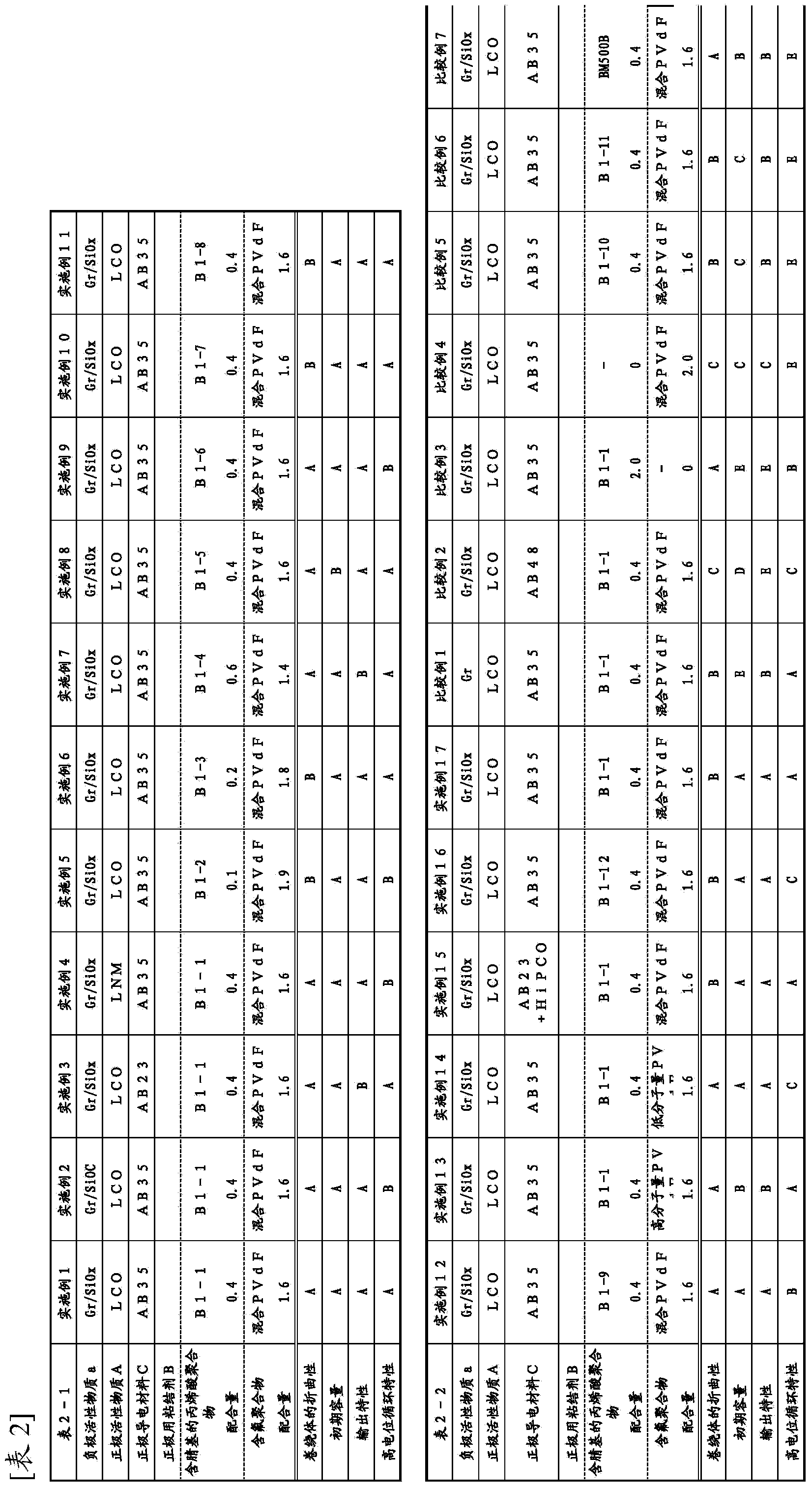

[0241] Hereinafter, the present invention will be described with reference to Examples, but the present invention is not limited to these Examples. It should be noted that the parts and % in this example are based on mass unless otherwise specified. In Examples and Comparative Examples, various physical properties were evaluated as follows.

[0242] (Measurement of swelling degree of non-aqueous electrolyte solution)

[0243] An 8% N-methylpyrrolidone (NMP) solution of a nitrile group-containing acrylic polymer was poured into a Teflon petri dish so that the thickness after drying might be 100 μm to prepare a polymer film. The obtained film was punched to 16 mmφ, and the weight was measured (the weight was set to "A"). 5% fluoroethylene carbonate was mixed in a mixture of ethylene carbonate and ethyl methyl carbonate in a weight ratio of 3:7, and lithium hexafluorophosphate (LiPF 6 ) to prepare a non-aqueous electrolyte. A film punched to 16 mmφ was immersed in 20 g of the...

preparation example 1

[0288] Production of nitrile group-containing acrylic polymer (B1-1)

[0289] 164 parts of ion-exchanged water, 59.5 parts of 2-ethylhexyl acrylate (2EHA), 20 parts of methacrylic acid (MAA), 20 parts of acrylonitrile (AN), and 2-acrylamide-2 were added to an autoclave equipped with a stirrer. -0.5 parts of methylpropanesulfonic acid (AMPS), 0.3 parts of potassium persulfate as a polymerization initiator, and 1.6 parts of sodium lauryl sulfate as an emulsifier, after stirring well, heated at 70° C. for 3 hours, and heated at 80° C. Polymerization was performed by heating for 2 hours to obtain an aqueous dispersion of the nitrile group-containing acrylic polymer (B1-1). In addition, the polymerization conversion rate calculated|required from solid content concentration was 96%. Separately, 500 parts of N-methylpyrrolidone was added to 100 parts of the aqueous dispersion, and after all water and residual monomers were evaporated under reduced pressure, 81 parts of N-methylpyrro...

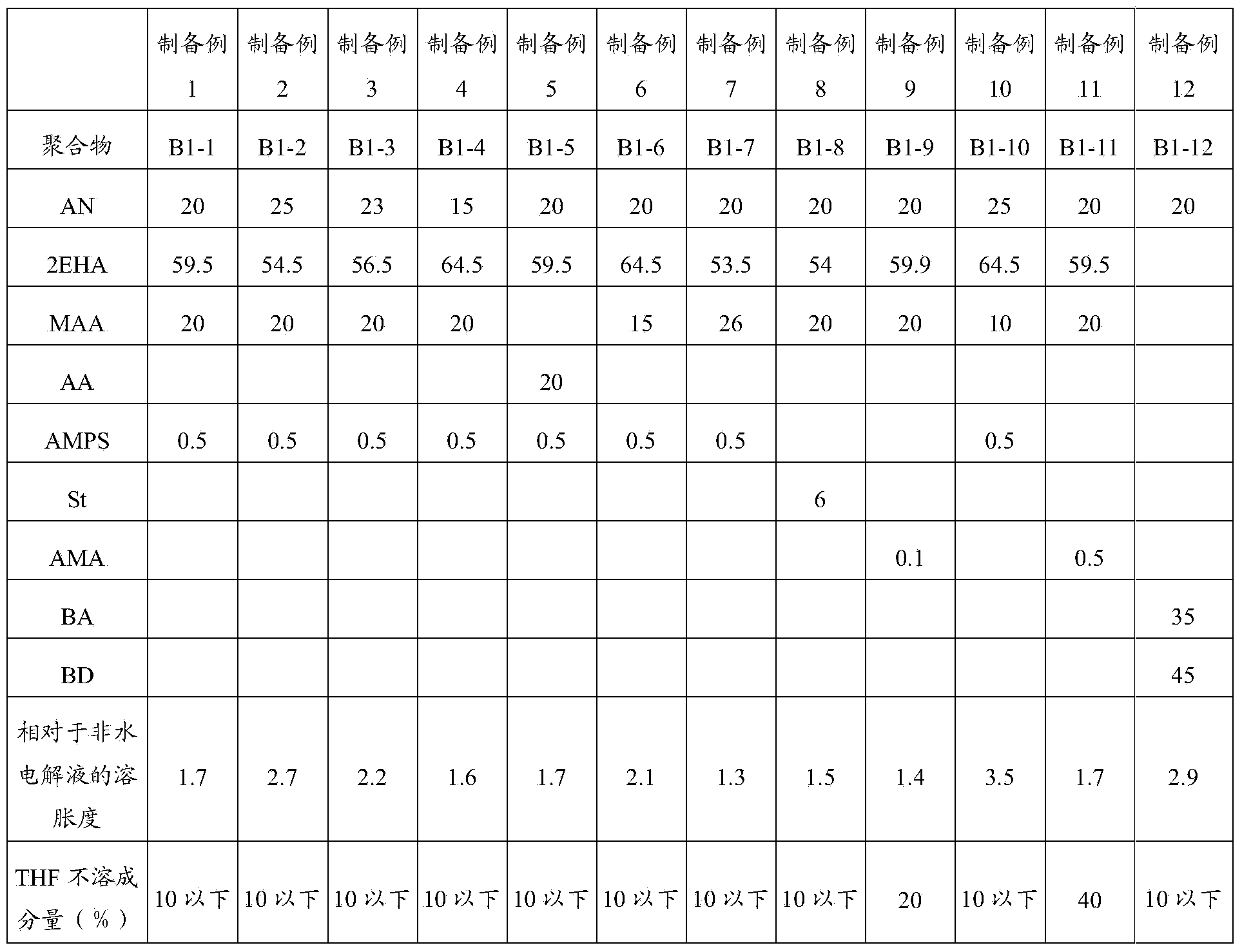

preparation example 2~11

[0291] Production of nitrile group-containing acrylic polymers (B1-2) to (B1-11)

[0292] The same procedure as in Preparation Example 1 was carried out, except that the feeding amount and the type of the monomers were changed as shown in Table 1. In addition, in Table 1, AN means acrylonitrile, 2EHA means 2-ethylhexyl acrylate, MAA means methacrylic acid, AA means acrylic acid, and AMPS means 2-acrylamido-2-methyl acrylate Propanesulfonic acid, St means styrene and AMA means allyl methacrylate. Table 1 shows the non-aqueous electrolyte swelling degree and THF insoluble content of the obtained polymers (B1-1) to (B1-11).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com