Battery cathode and lithium ion secondary battery comprising same

A secondary battery and lithium ion technology, applied in secondary batteries, battery electrodes, electrode manufacturing, etc., can solve the problems of high battery capacity and good battery cycle performance, and achieve improved cycle performance and high-current discharge performance, The effect of high specific capacity and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

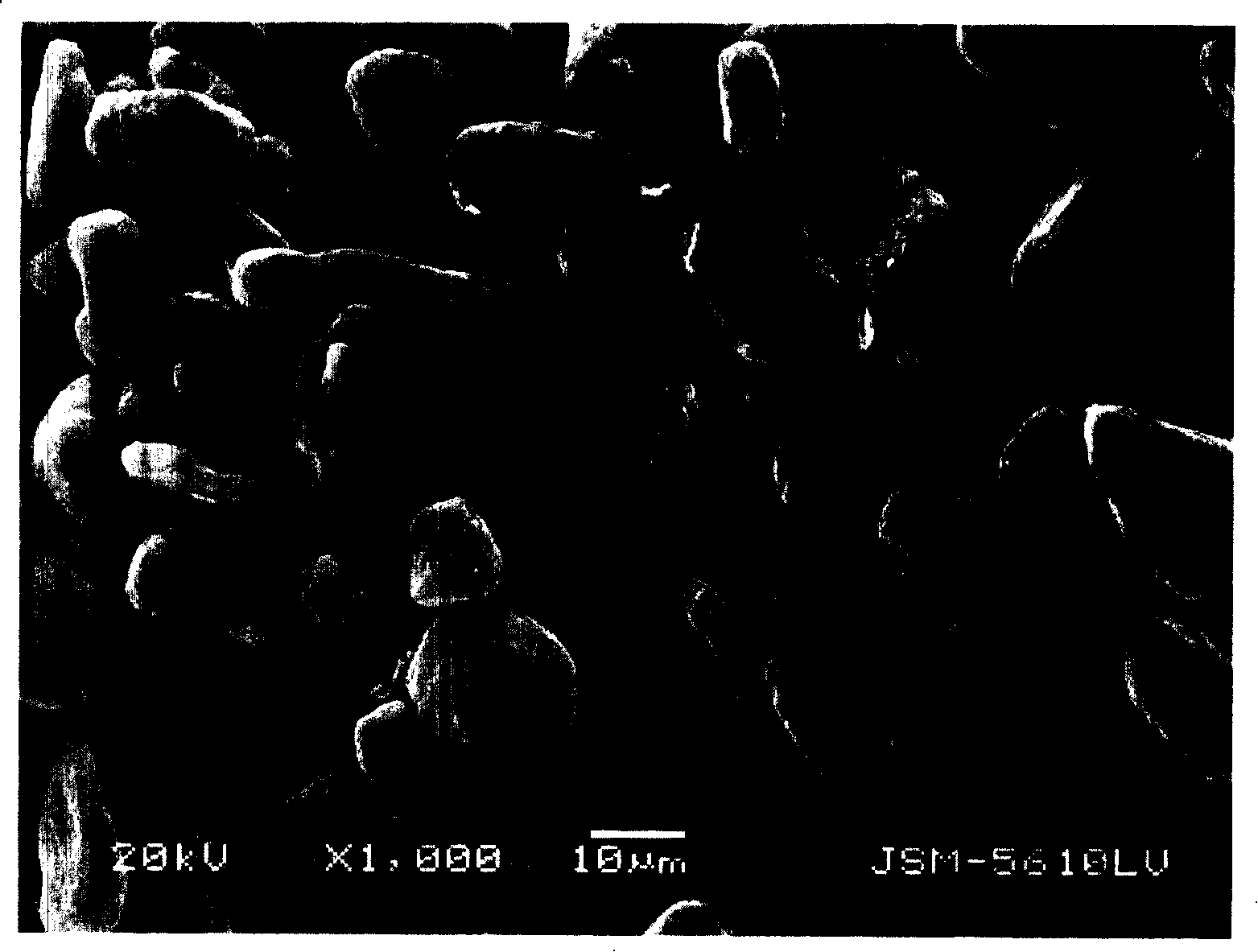

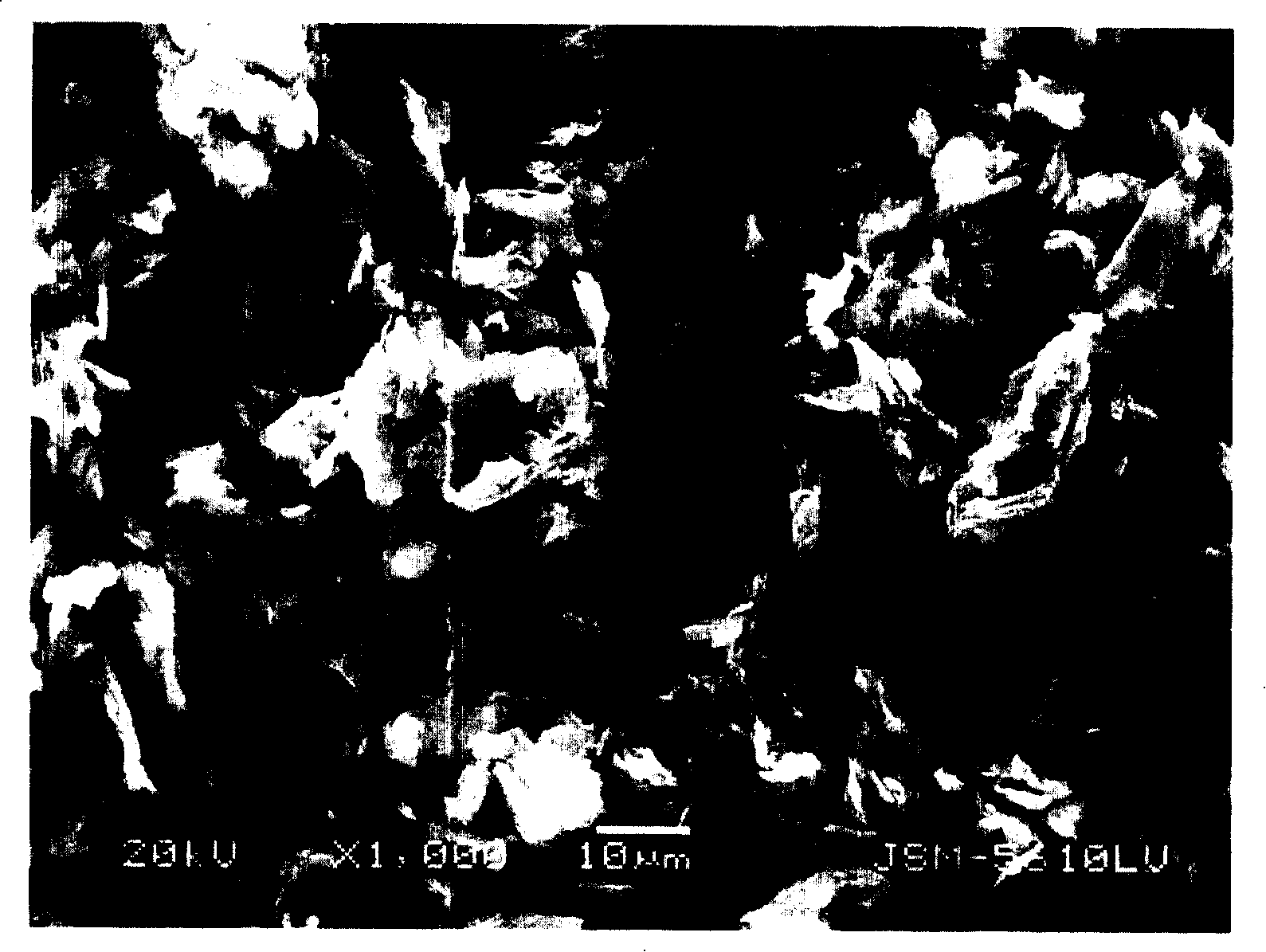

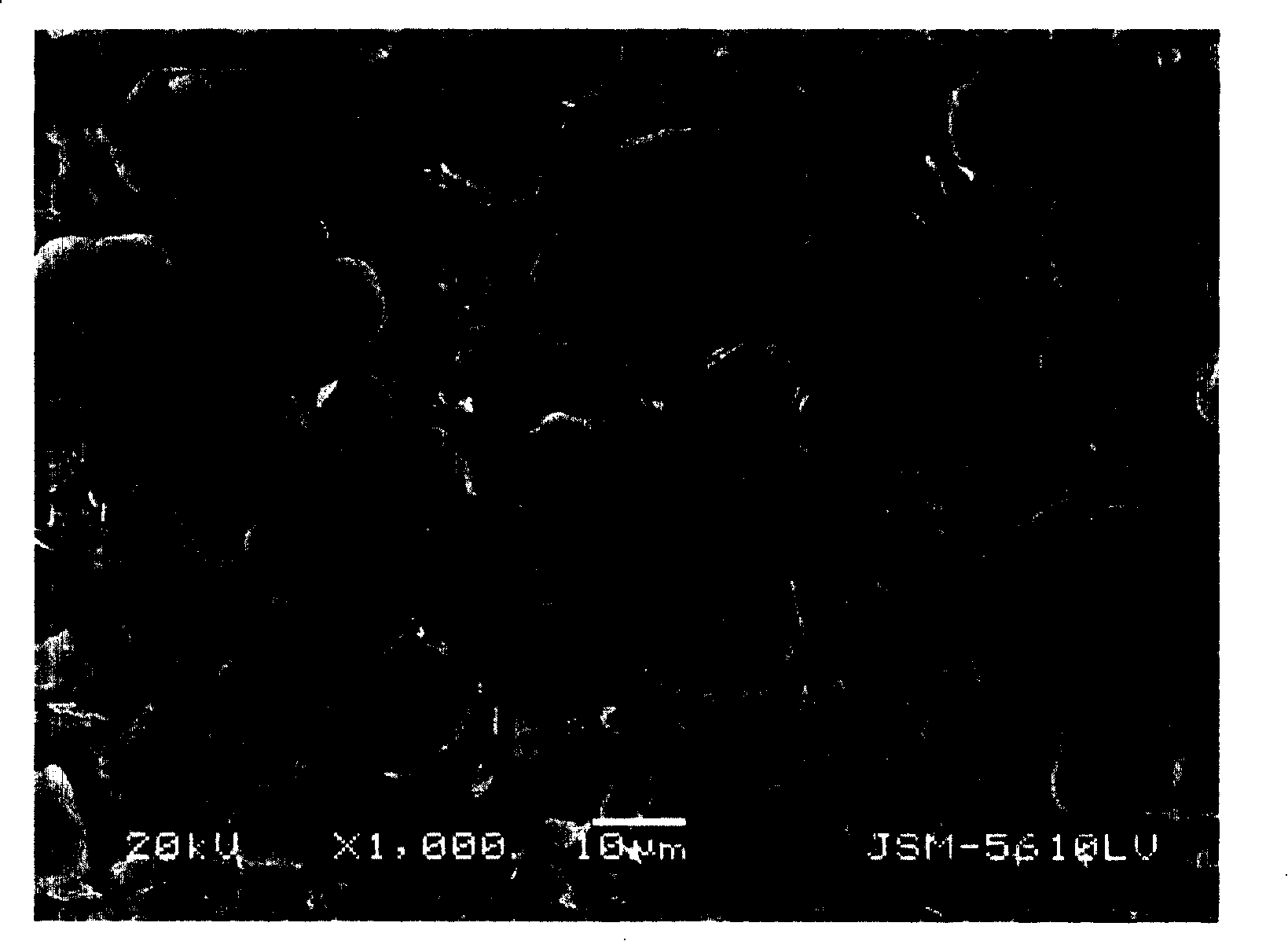

[0049]The method for preparing a battery negative electrode provided by the present invention includes coating and / or filling a slurry containing a negative electrode material on a current collector, drying, and rolling. The negative electrode material includes a negative electrode active material and a negative electrode binder. The active material is a mixed graphite of natural graphite and artificial graphite, wherein the natural graphite is spherical natural graphite, the artificial graphite is micro-particle flake-shaped artificial graphite, and the particle diameter of the spherical natural graphite is larger than the micro-particle flake-shaped artificial graphite The particle diameter of the spherical natural graphite and the median diameter D of the micro-particle scaly artificial graphite 50 The difference is 4-25 microns; the median diameter D of the micro-particle scaly artificial graphite 50 It is 0.3-6 microns; the weight ratio of the spherical natural graphite to th...

Embodiment 1

[0061] This embodiment illustrates the negative electrode provided by the present invention, a preparation method thereof, and a battery including the negative electrode.

[0062] (1) Preparation of negative electrode

[0063] Spherical natural graphite (product of Qingdao Taineng Company, median diameter D 50 It is 17.54 microns, the distance between the microcrystalline layers is d 002 The correction value is 0.33650 nm, and the specific surface area obtained by the low-temperature nitrogen adsorption BET method is 2.2 meters 2 / G) and micro-particle scaly artificial graphite (commodity of Changsha Xingcheng Company, median diameter D 50 It is 4.6 microns, the microcrystalline layer spacing d 002 The correction value is 0.33784 nm, and the specific surface area obtained by the low-temperature nitrogen adsorption BET method is 11.95 meters 2 / G) The mixed graphite is obtained after thorough mechanical mixing at a weight ratio of 1:0.2, which is ready for use.

[0064] Add 100 gra...

Embodiment 2-7

[0088] This embodiment illustrates the negative electrode provided by the present invention, a preparation method thereof, and a battery including the negative electrode.

[0089] The negative electrode and the battery A2-A7 including the negative electrode were prepared according to the method of Example 1. The difference is that the ratio of the negative electrode active material and the median diameter D 50 , As shown in Table 1 below.

[0090] Table 1

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com