A kind of in-situ precipitated oxide-coated positive electrode material for lithium-ion batteries and its preparation method and application

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, batteries, secondary batteries, etc., can solve the problems of matrix material particle agglomeration, serious, inability to achieve coating, etc., to suppress structural changes, improve Coulomb efficiency, and easily effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

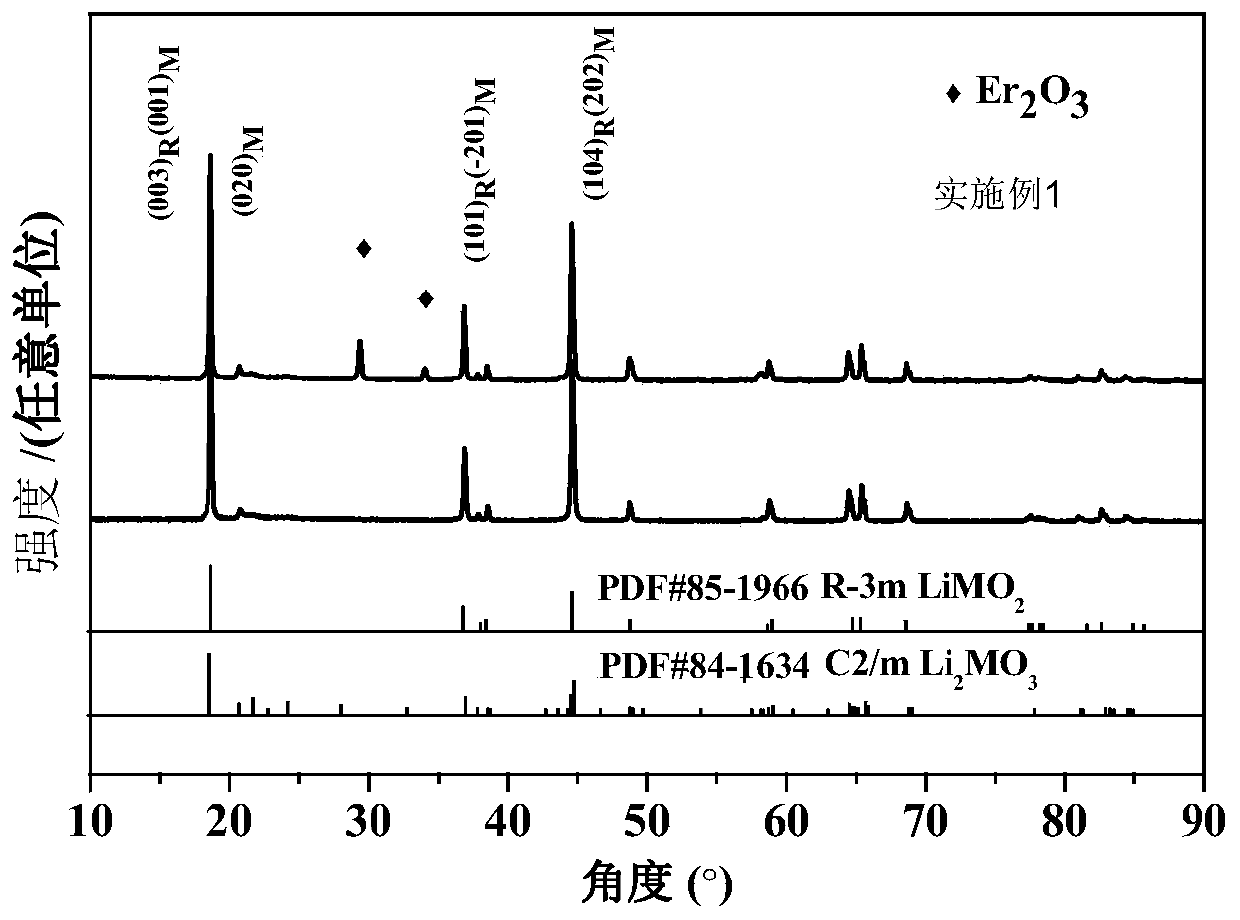

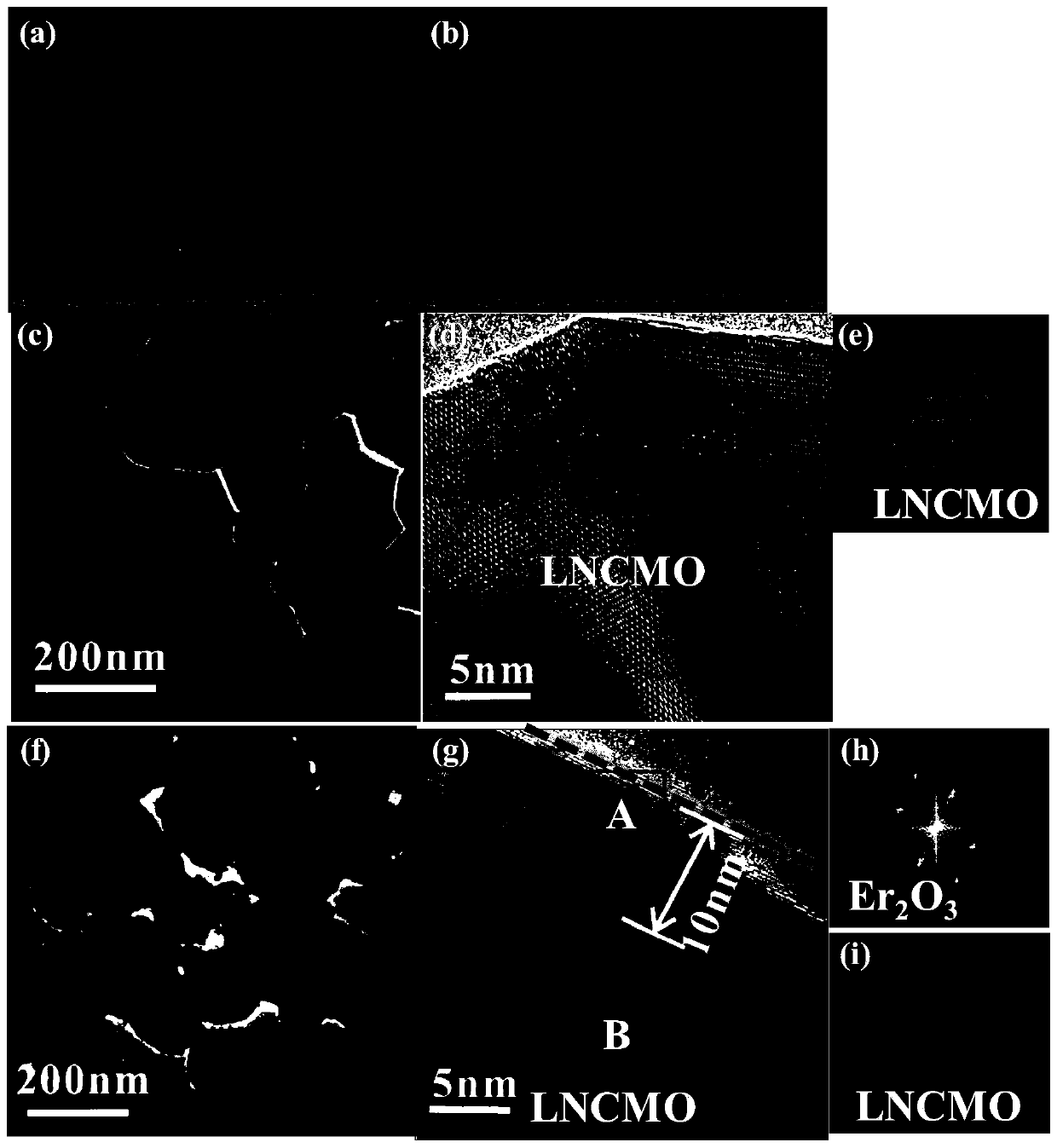

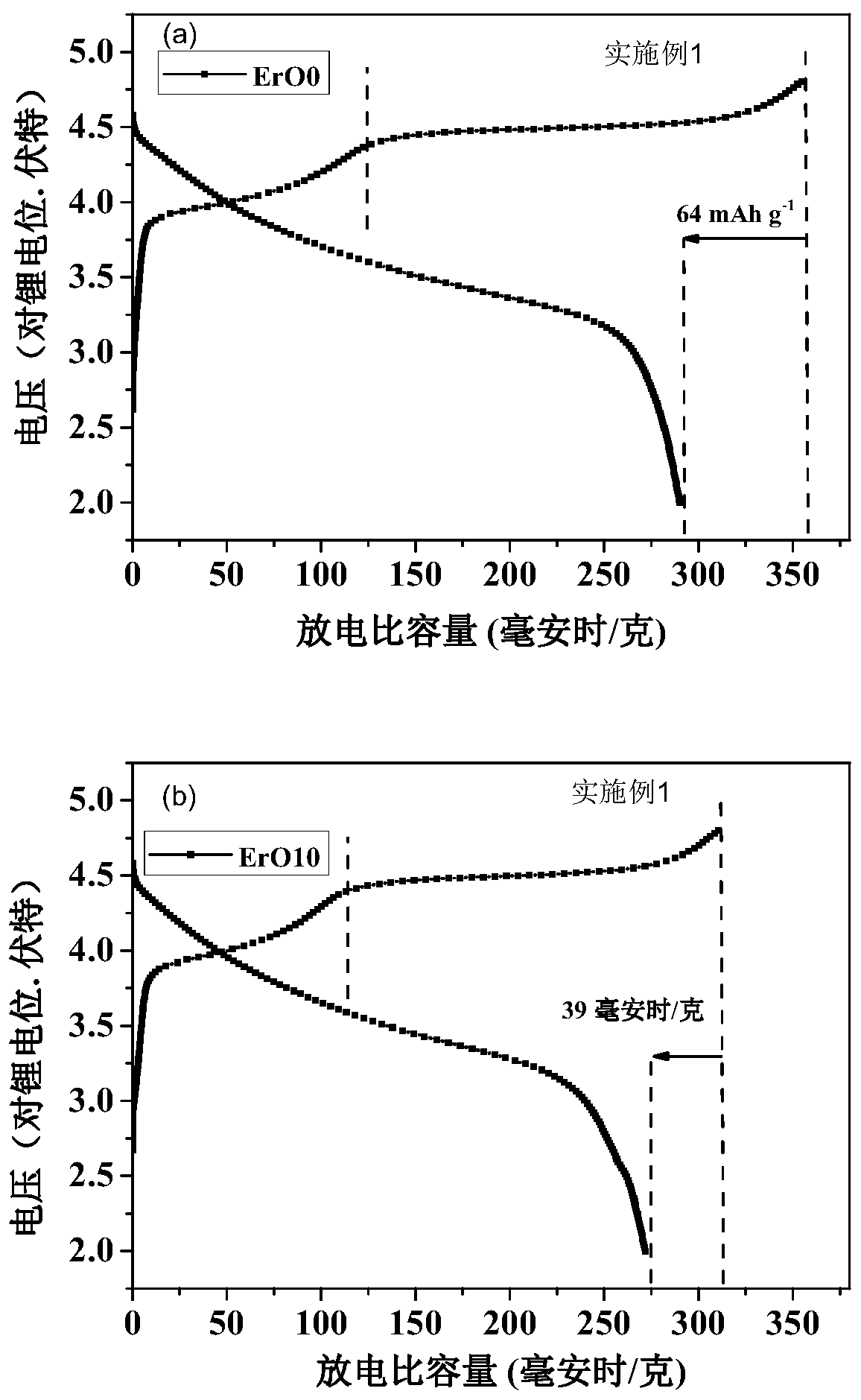

[0049] In situ Precipitation of Er Synthesized by Spray Pyrolysis 2 o 3 Cover 0.5Li 2 MnO 3 -0.5LiNi 0.33 co 0.33 mn 0.33 o 2 (LNCMO@Er 2 o 3 ) Cathode material

[0050] In situ precipitation of Er 2 o 3 Cover 0.5Li 2 MnO 3 -0.5LiNi 0.33 co 0.33 mn 0.33 o 2 (LNCMO@Er 2 o 3 ) Preparation of positive electrode material: Li, Ni, Co, Mn acetate are added to a certain amount of deionized water according to the stoichiometric ratio, and mechanical stirring is used to obtain a uniform reaction solution; then 10% (Er 2 o 3 , 10 wt%) adding erbium acetate (ErAC) into the reaction solution; performing spray pyrolysis on the reaction solution to obtain a precursor. The resulting precursors were heat-treated at 900 °C for 10 hours to obtain different Er 2 o 3 Coated LNCMO cathode material.

[0051] Will LNCMO@Er 2 o 3 The positive electrode material and the binder are mixed in a certain proportion, and magnetically stirred for 4 hours to obtain a uniform slurry, a...

Embodiment 2

[0058] In situ Precipitation of Er Synthesized by Spray Pyrolysis 2 o 3 Cover 0.5Li 2 MnO 3 -0.5LiNi 0.33 co 0.33 mn 0.33 o 2 (LNCMO@Er 2 o 3 ) Cathode material—the influence of different erbium raw materials

[0059] In situ precipitation of Er 2 o 3 Cover 0.5Li 2 MnO 3 -0.5LiNi 0.33 co 0.33 mn 0.33 o 2 (LNCMO@Er 2 o 3 ) Preparation of positive electrode material: Li, Ni, Co, Mn acetate are added to a certain amount of deionized water according to the stoichiometric ratio, and mechanical stirring is used to obtain a uniform reaction solution; then 10% (Er 2 o 3 , 10wt%) different kinds of erbium salt raw materials (erbium nitrate, erbium carbonate, erbium oxalate) were added to the reaction solution; the reaction solution was sprayed and pyrolyzed to obtain the precursor. The resulting precursors were heat-treated at 900 °C for 10 hours to obtain different Er 2 o 3 Coated LNCMO cathode material.

[0060] The preparation of the electrode and the assembly...

Embodiment 3

[0063] Co-precipitation method to prepare LNCMO@Er 2 o 3 Cathode material

[0064] In situ precipitation of Er 2 o 3 Cover 0.5Li 2 MnO 3 -0.5LiNi 0.33 co 0.33 mn 0.33 o 2 (LNCMO@Er 2 o 3 ) Preparation of positive electrode material: by stoichiometric ratio Li, Ni, Co, Mn nitrate are added to a certain amount of deionized water, then by coating amount mass percentage 10% (Er 2 o 3 , 10 wt%) adding erbium nitrate to the reaction solution, using ammonia water to adjust the pH of the solution to 11, mechanically stirring for 10 hours, then using suction filtration to obtain the reactant, drying at 120 degrees Celsius for 12 hours to obtain the precursor. The resulting precursors were heat-treated at 900 °C for 10 hours to obtain different Er 2 o 3 Coated LNCMO cathode material.

[0065] The preparation of the electrode and the assembly of the battery are the same as in Example 1.

[0066] Figure 6 For original LNCMO and mass percent 10% Er 2 o 3 XRD of coated L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com