A lithium-rich positive electrode material/conductive flexible polymer composite material and its preparation method and application

A technology of lithium-rich positive electrode materials and flexible polymers, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as structural damage, uneven migration of lithium ions, and failure of electrode materials to pulverize, so as to improve electrochemical performance, Good environmental stability and the effect of relieving mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

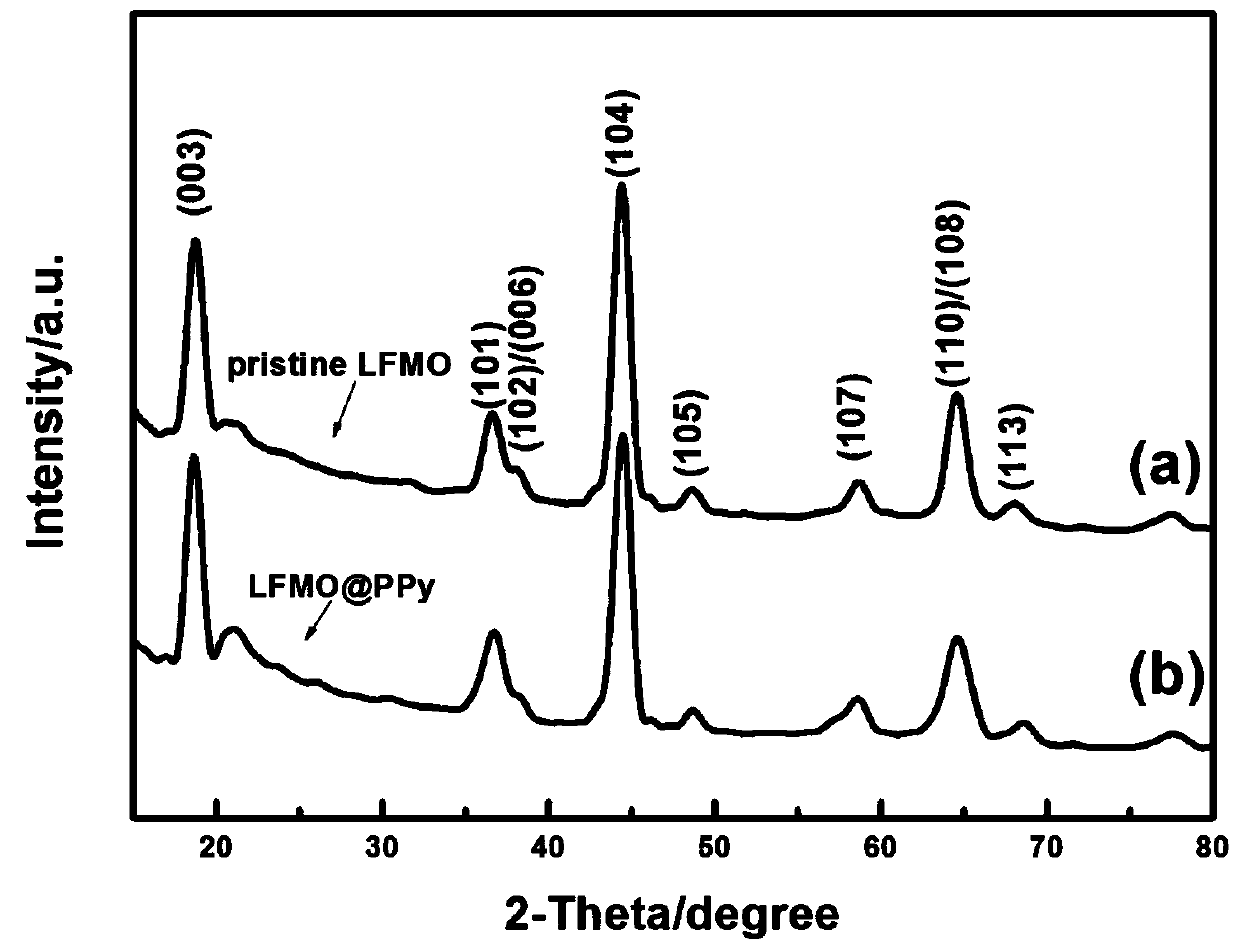

Embodiment 1

[0028] First weigh 0.7Li 2 MnO 3 0.3LiFeO 2 Add 500mg powder of lithium-rich cathode material to 20mL distilled water / ethanol / ethylene glycol / nitromethylpyrrolidone 5:2:2:1 mixed solution, add Synde-146 (specifically, polymer dispersant containing amine anchoring groups, Zhuhai Xiande New Material Technology Co., Ltd.) 2 mL, ultrasonically dispersed for 60 min, transferred to a high-energy ball mill tank, added agate balls at a ball-to-material mass ratio of 10:1, and mechanically ball milled for 12 h at a speed of 360 r / min to obtain dispersion A.

[0029]Then, 0.05 g of the prepared polypyrrole nanowires was added to 20 mL of distilled water / ethanol / ethylene glycol / nitromethylpyrrolidone 5:2:2:1 mixed solution, and Synde-146 (specifically, amine-containing anchoring group Polymer dispersant, Zhuhai Xiande New Material Technology Co., Ltd.), ultrasonically dispersed for 60 minutes, moved into the high-energy ball mill tank, added agate balls with a ball-to-material mass rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com