Preparation method of modified cobalt vanadate material and supercapacitor

A cobalt vanadate and modified technology, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, can solve problems such as poor cycle performance, and achieve the effects of increasing contact area, improving cycle performance and high specific capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

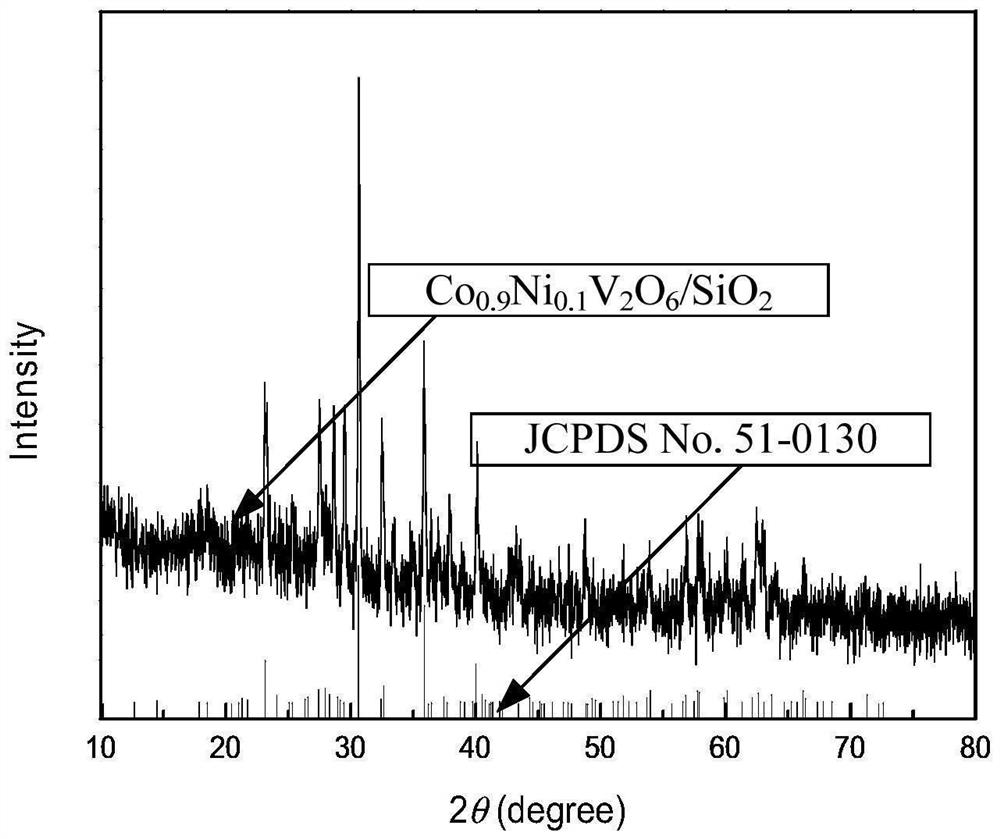

[0040] The invention provides a preparation method of modified cobalt vanadate material, which aims to provide an electrode material with good cycle performance and high specific capacitance. In one embodiment, the preparation method comprises the following steps:

[0041] Step S10: dissolve cobalt nitrate hexahydrate and nickel nitrate hexahydrate in deionized water to obtain a mixed solution. Under stirring conditions, add complexing agent, surfactant and ammonium metavanadate solution to the mixed solution to obtain a reaction solution. Move the reaction solution into a hydrothermal reactor and react at 1101100 ℃ for 11110 hours to obtain a solid-liquid mixture.

[0042] Specifically, cobalt nitrate hexahydrate and nickel nitrate hexahydrate are dissolved in deionized water to obtain the mixed solution. Under the stirring of magnetic stirrer, complexing agent and surfactant are added. After magnetic stirring for 0.5 hours, ammonium metavanadate solution is added and stirred for...

Embodiment 1

[0062] (1) Add 1.13g ammonium metavanadate into 50ml deionized water, stir with a magnetic stirrer at a stirring rate of 300 rpm, heat in a water bath at 10 ℃ for 0.5h, and dissolve to obtain ammonium metavanadate solution.

[0063] (1) Dissolve 1.31g of cobalt nitrate hexahydrate and 0.15g of nickel nitrate hexahydrate in 10ml deionized water to obtain the mixed solution. Stir with a magnetic stirrer at a stirring rate of 300 rpm, then add 1.11g of citric acid monohydrate and 0.15g of sodium dodecyl sulfate. After magnetic stirring for 0.5 hours, add the above ammonium metavanadate solution, add deionized water to make the total volume of the solution 150ml, and continue stirring for 3 hours, The reaction solution (that is, the concentration of ammonium metavanadate in the reaction solution is 0.07mol / l), and the molar ratio of each component added in the reaction solution is cobalt nitrate hexahydrate: nickel nitrate hexahydrate: citric acid monohydrate: sodium dodecyl sulfate: ...

Embodiment 2

[0068] (1) Add 1.11g ammonium metavanadate into 50ml deionized water, stir with a magnetic stirrer at a stirring rate of 100 rpm, heat in a water bath at 10 ℃ for 1 hour, and dissolve to obtain ammonium metavanadate solution.

[0069] (1) Dissolve 1.17g cobalt nitrate hexahydrate and 0.15g nickel nitrate hexahydrate in 10ml deionized water to obtain the mixed solution. Stir with a magnetic stirrer at a stirring rate of 300 rpm, add 3.35g citric acid monohydrate and 0.13g sodium dodecyl sulfate, and add the above ammonium metavanadate solution after magnetic stirring for 0.5 hours. Add deionized water to make the total volume of the solution 150ml, and continue stirring for 4 hours, The reaction solution (that is, the concentration of ammonium metavanadate in the reaction solution is 0.11mol / l), and the molar ratio of each component added in the reaction solution is cobalt nitrate hexahydrate: nickel nitrate hexahydrate: citric acid monohydrate: sodium dodecyl sulfate: ammonium met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com