High-powered lithium ferric phosphate dynamic battery, and preparation technique

A technology for lithium iron phosphate and power batteries, which is applied in high-power lithium iron phosphate power batteries and its manufacturing process belongs to the field of batteries, which can solve the problems of poor electrical conductivity and ion diffusion performance, low bulk density and tap density, and high battery current Discharge performance is poor and other problems, to achieve good electrochemical performance and processing performance, high-current discharge performance improvement, electrical conductivity and ion diffusion performance to improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

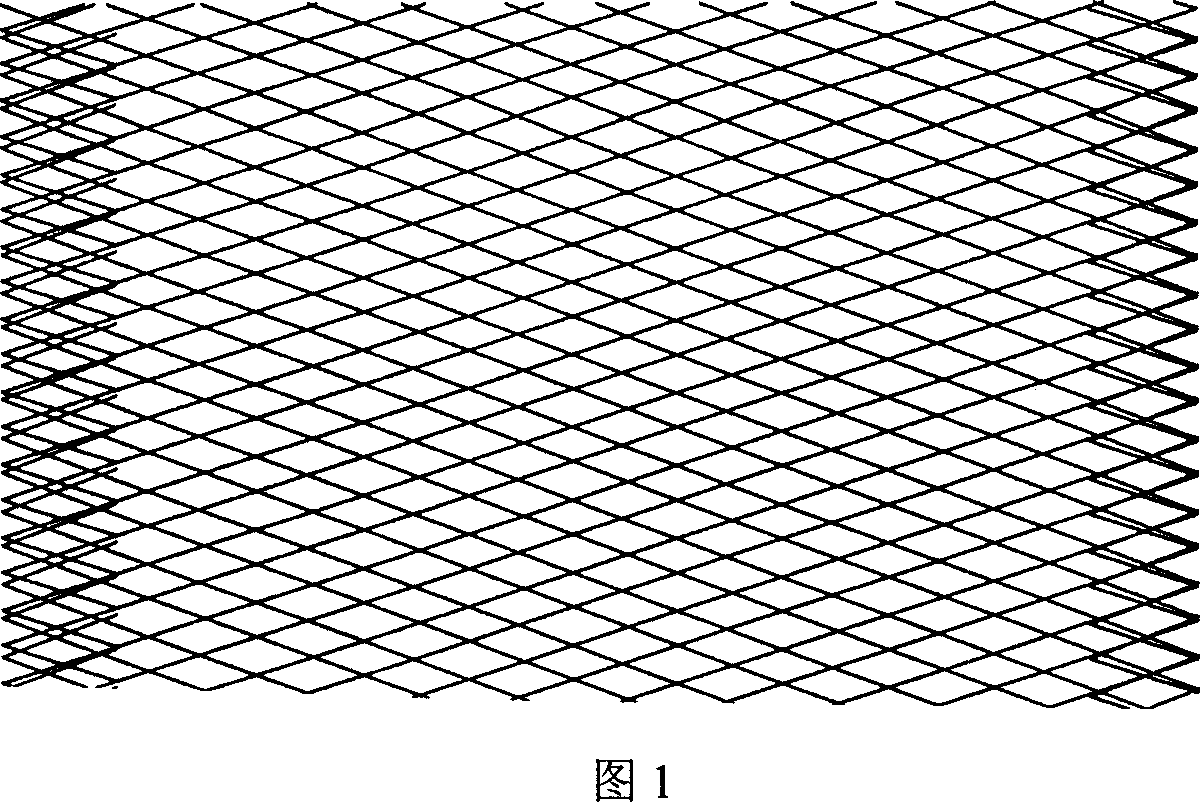

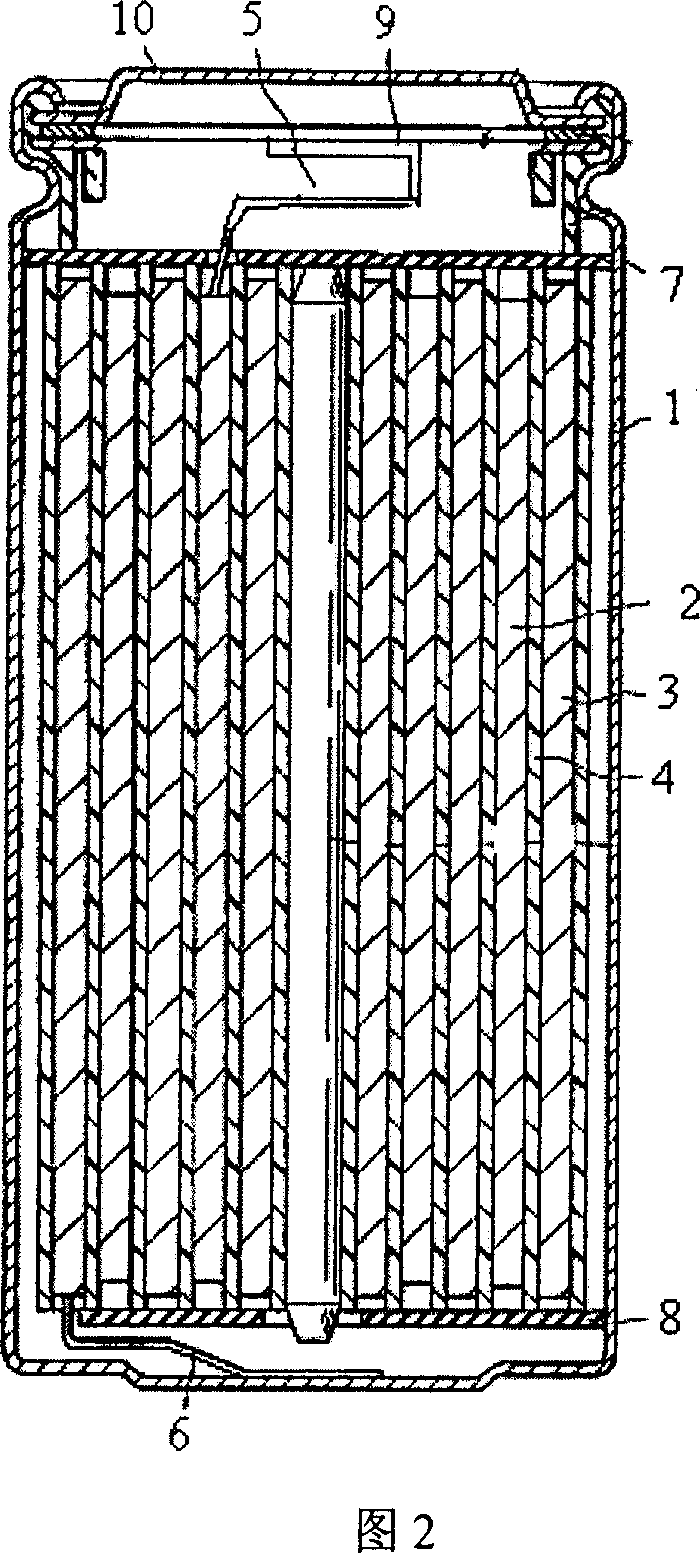

[0070] 1. Lithium iron phosphate (85%), carbon black (5%), and graphite (5%) are mixed and ground, dried and premixed, and made into positive electrode powder. Mix the mixed positive electrode powder with deionized water of acrylic polymer (5%) (F103 binder) to make a slurry with a viscosity between 6000 and 9000mPaS, and coat the slurry on the cable-stayed aluminum mesh After being dried at 110°C, the two sides are rolled and pressed to form a pole piece with a thickness of 200 μ and a compacted density of 2.2 g / cm 3 , to obtain the positive pole piece.

[0071] 2. Mix natural graphite (93%) with deionized water containing sodium carboxymethyl cellulose (2%) and styrene-butadiene rubber (5%) binder to make a slurry with a viscosity between 3000 and 5000mPaS. Apply the slurry evenly on both sides of the copper foil, dry it at 120°C, and then roll it to form a pole piece with a thickness of 120μ and a compacted density of 1.6g / cm 3 , to obtain the negative electrode sheet. T...

Embodiment 2

[0082] The steps and procedures described in Implementation 1 are used to prepare assembled batteries, the only difference is the positive electrode, according to the composition of lithium iron phosphate (82%), carbon black (5%), graphite (5%), and nanometer aluminum oxide (3%) Proportionally mixed and ground, the prepared positive electrode powder was mixed with deionized water of acrylic polymer (5%) (F103 binder) to make a slurry.

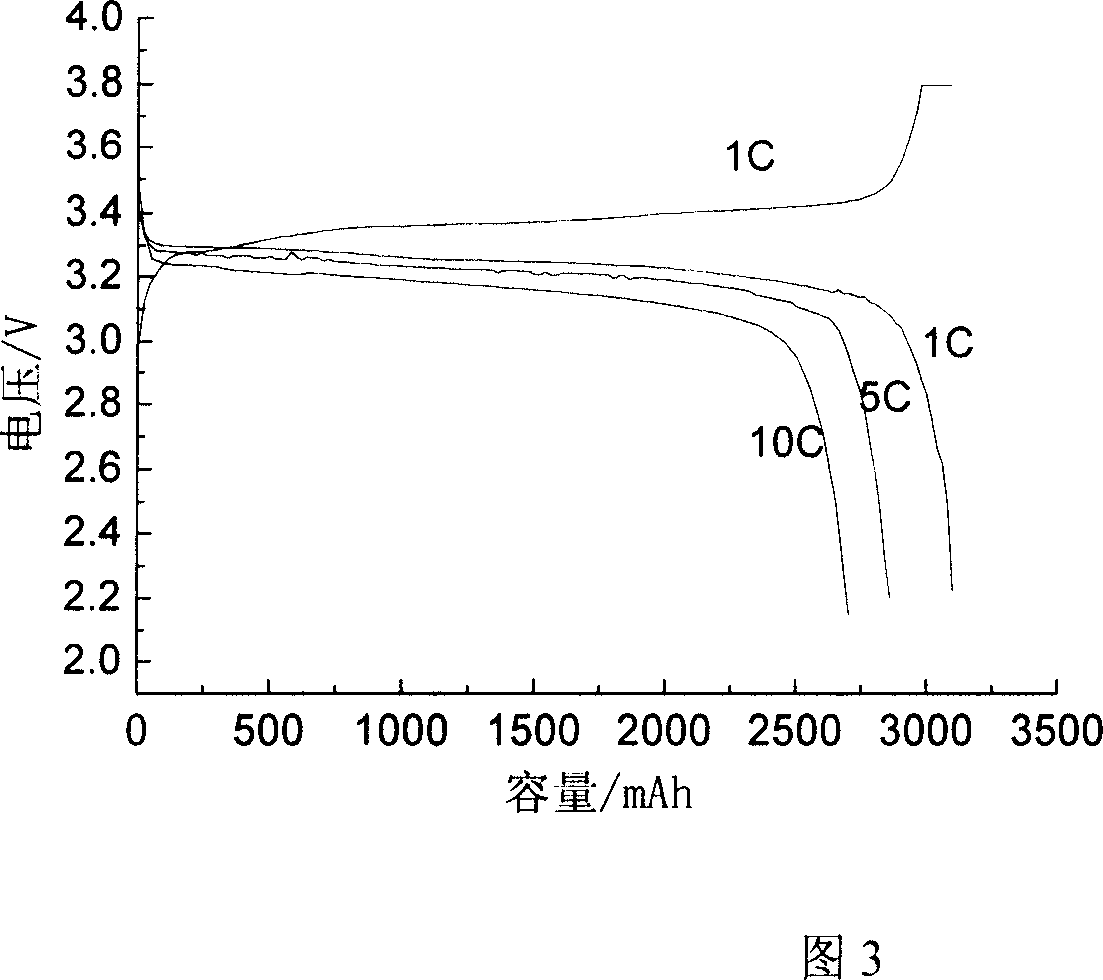

[0083] After testing, the charge and discharge voltage is 2.0-3.8V, discharge at 1C, the discharge platform is 3.2V, the battery capacity is about 3200mAh, and the capacity retention rate after 400 cycles is 93.8%. The battery can discharge 91.2% of its capacity at 10C.

[0084] As shown in Figure 5, the different current discharge curves of D-type batteries prepared in Example 2.

[0085] As shown in Figure 6, the preparation of Example 2 is a D-type battery 1C charge-discharge cycle life.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com