Preparation method of safe high-rate and all-solid-state battery

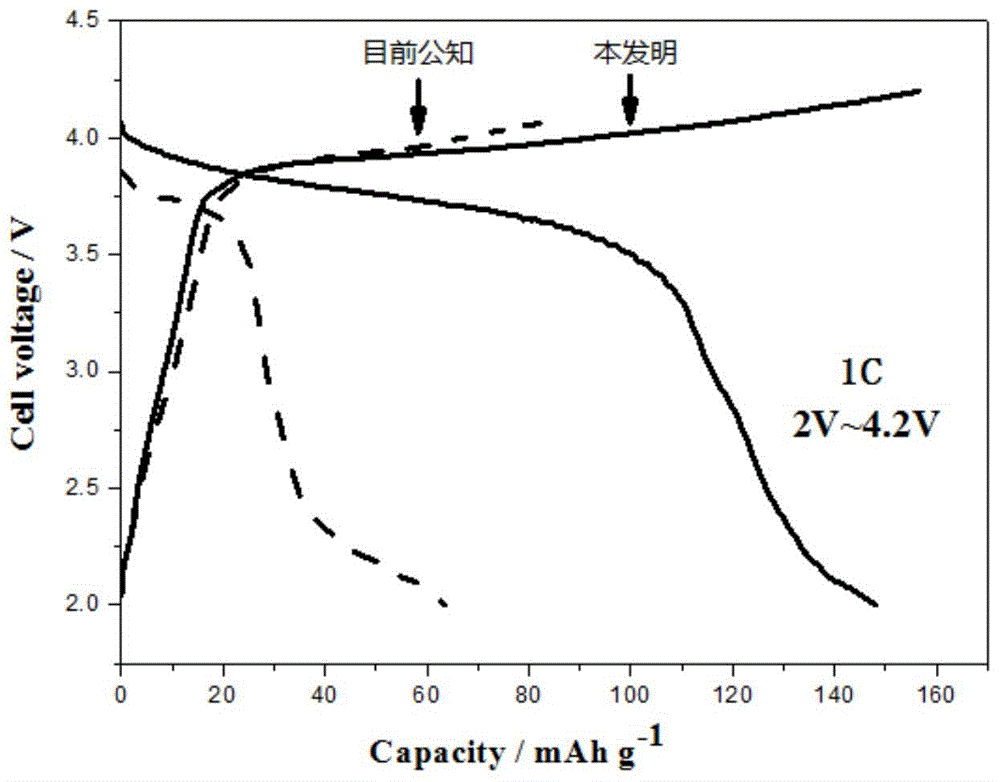

An all-solid-state battery, high-rate technology, applied in the manufacture of electrolyte batteries, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems affecting the rate performance of all-solid-state batteries, and achieve high current discharge capacity and good interface compatibility. , the effect of good lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

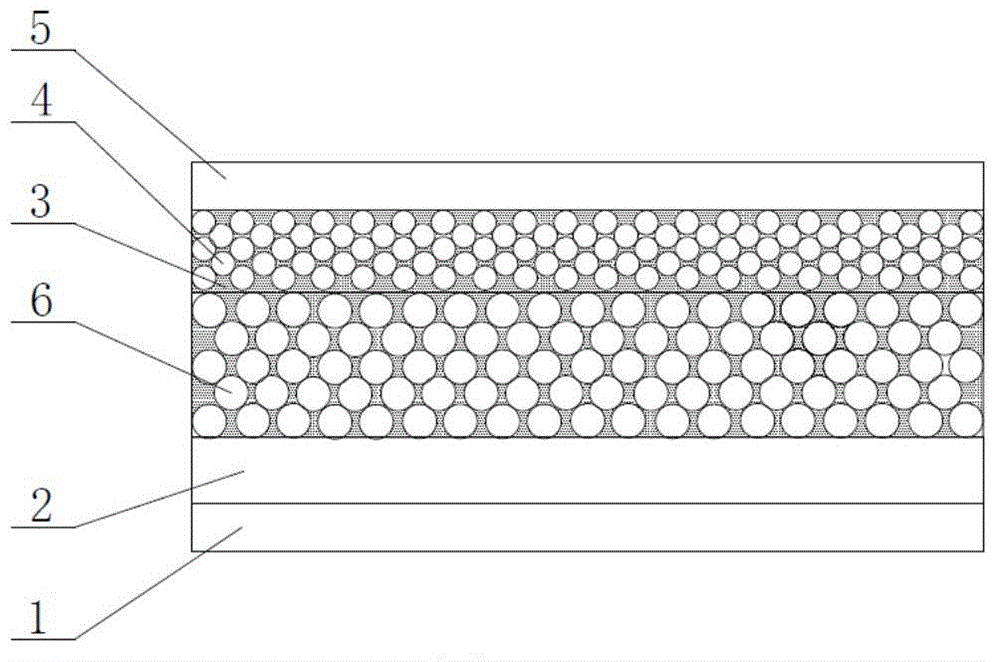

[0031] A method for preparing a safe high-rate all-solid-state battery is characterized in that it includes the following manufacturing steps:

[0032] Step 1: In a dry environment, press the negative electrode current collector, negative electrode material, solid electrolyte, composite positive electrode, and positive electrode current collector into a battery pressing mold from bottom to top to form an all-solid-state battery before liquid injection;

[0033] Step 2: In a vacuum environment, inject a liquid electrolyte solution into the all-solid-state battery before liquid injection prepared in step 1;

[0034] Step 3: Inflate the vacuum environment after the ionic liquid was injected in Step 2, and take it out from the battery pressing mold to complete the production process of the safe high-rate all-solid-state battery.

[0035] The negative electrode current collector is a copper sheet, a silver sheet or a stainless steel sheet.

[0036] The negative electrode material ...

Embodiment

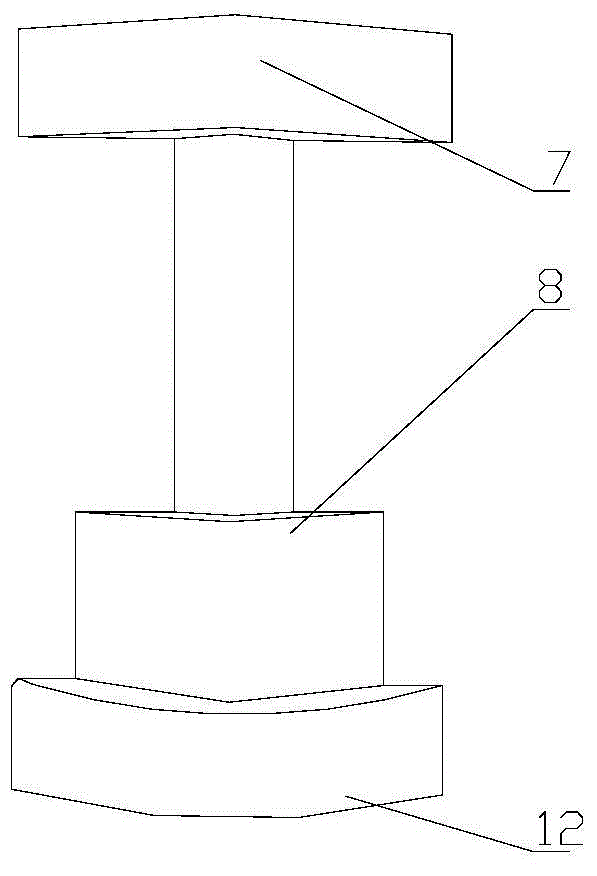

[0045] Make the battery pressing mold:

[0046] Such as Figure 3-Figure 4 As shown, the lower bearing block 12 and the upper bearing block 7 with coaxial convex circles, the straight cylindrical sleeve 8 sleeved on the lower bearing block and the upper bearing block, and the lower bearing The lower jacket 11 between the pressure block and the sleeve and the upper jacket 9 between the upper pressure block and the sleeve; a stripper ring between the lower jacket and the upper jacket made of polytetrafluoro or nylon 10. After putting the lower jacket on the lower bearing block, place a demoulding ring with the same inner and outer diameter as the lower jacket on the lower jacket, then put the sleeve into the demoulding ring and the lower jacket, and put the upper jacket Put it on the release ring in the sleeve and put it in the drying oven, and perform the following operations:

[0047] (1) A stainless steel sheet with a diameter of Φ10 is selected as the negative electrode cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com