Patents

Literature

51results about How to "Increase available resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

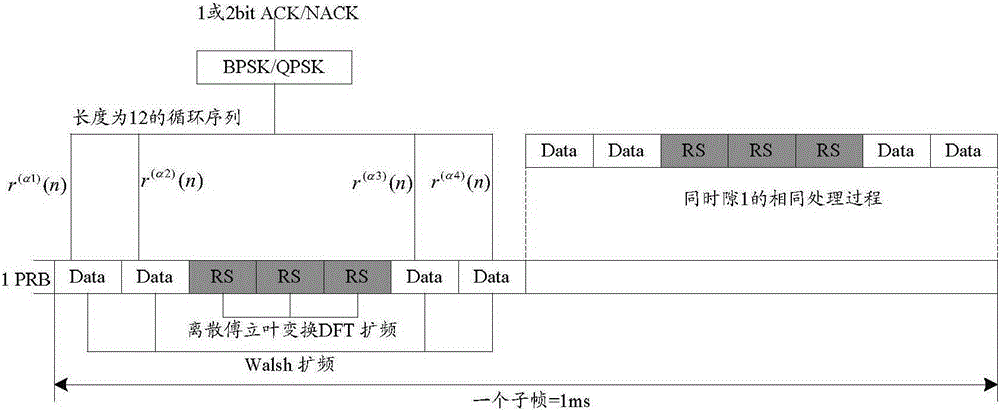

Method and system for sending SRS (survey reference signal)

InactiveCN102223726AIncrease available resourcesIncrease multiplexing capacityModulated-carrier systemsMultiplex code allocationTime domainMultiplexing

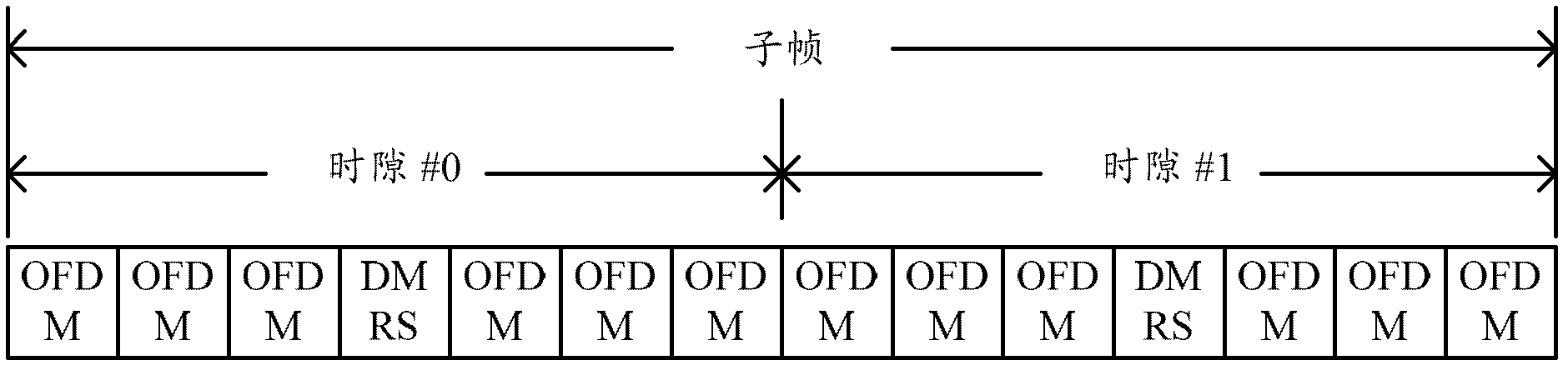

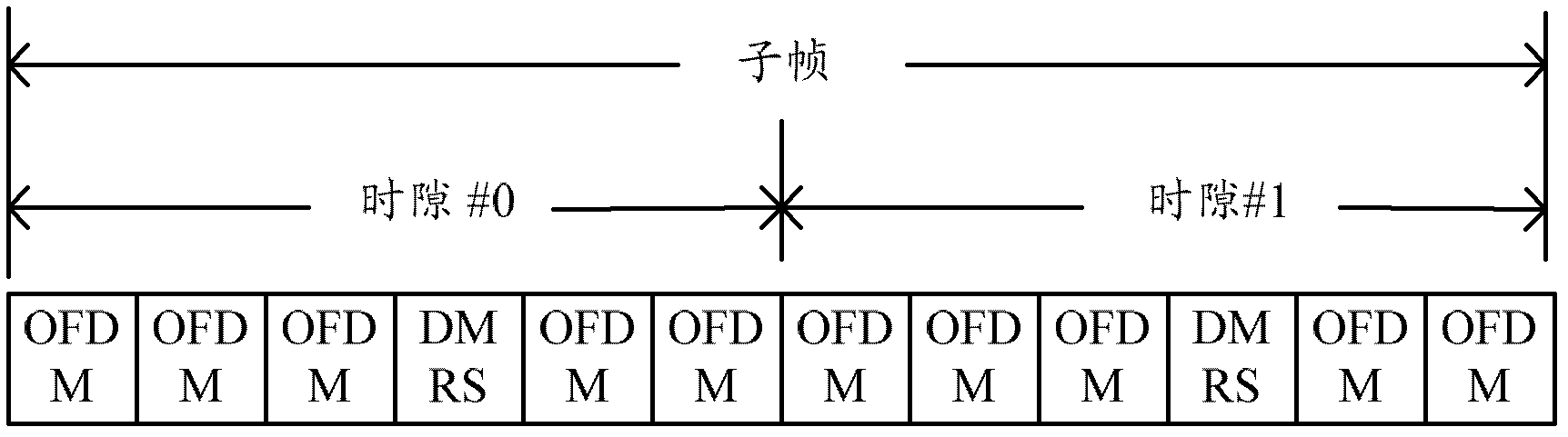

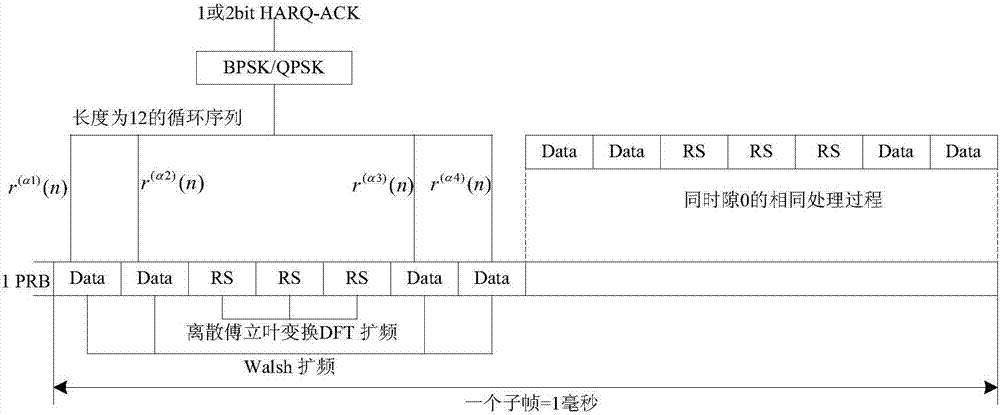

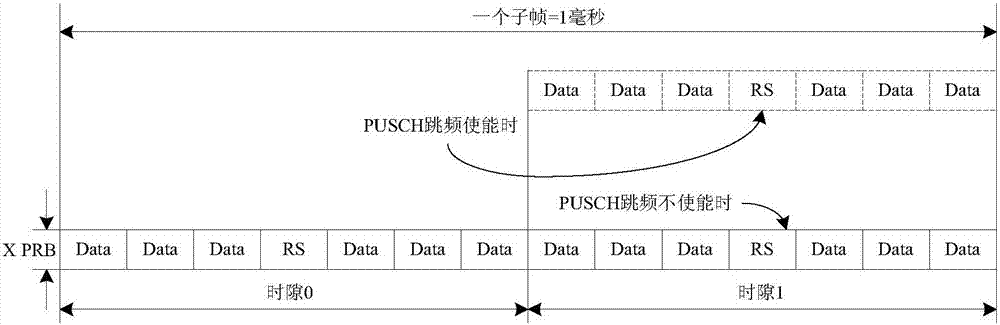

The invention discloses a method and a system for sending an SRS (survey reference signal); the method comprises the following steps: user equipment (UE) transmits the SRS to a base station on a time domain resource, a frequency domain resource and / or a code domain resource, wherein the time domain resource comprises the last time domain sign, the first time domain sign or the last but one time domain sign of a sub-frame of an SRS cycle; the frequency domain resource comprises a frequency domain location of the SRS or a sending frequency comb of the SRS, the code domain resource is obtained by the following method: a sequence group number of the SRS is generated by the UE according to a parameter which is configured for the UE by the base station through a high level signaling and is proprietary by users, and the code domain resource which is needed for sending the SRS is determined according to the generated sequence group number of the SRS. The available resource of the SRS is increased, the user multiplexing capacity of the SRS is improved, and the channel estimation quality of the base station to the SRS is improved, therefore, the application of the coordinated multi-point transmission technology to the system is supported effectively.

Owner:ZTE CORP

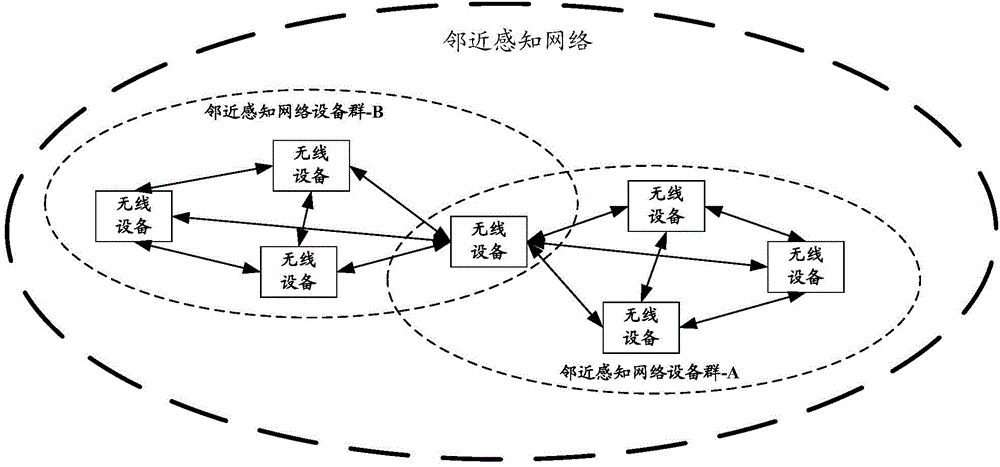

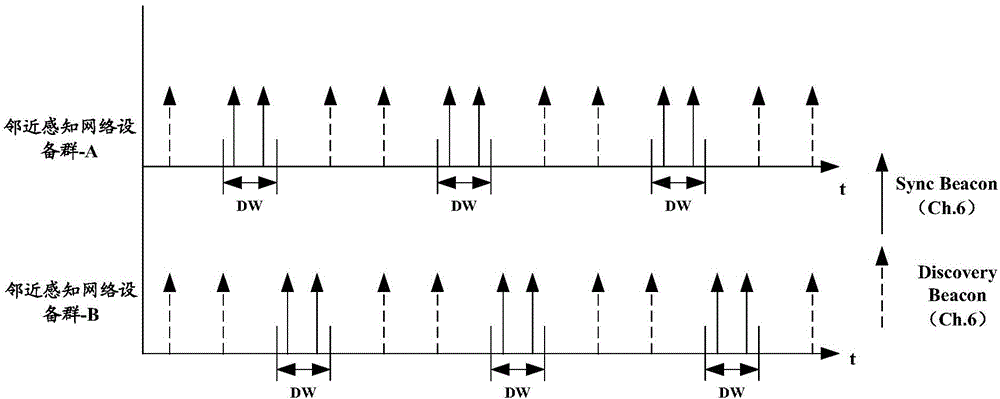

Method, device and system for joining in neighbor awareness network cluster

ActiveCN104378800AShort working hoursReduce power consumptionAssess restrictionNetwork topologiesTelecommunicationsNetwork clustering

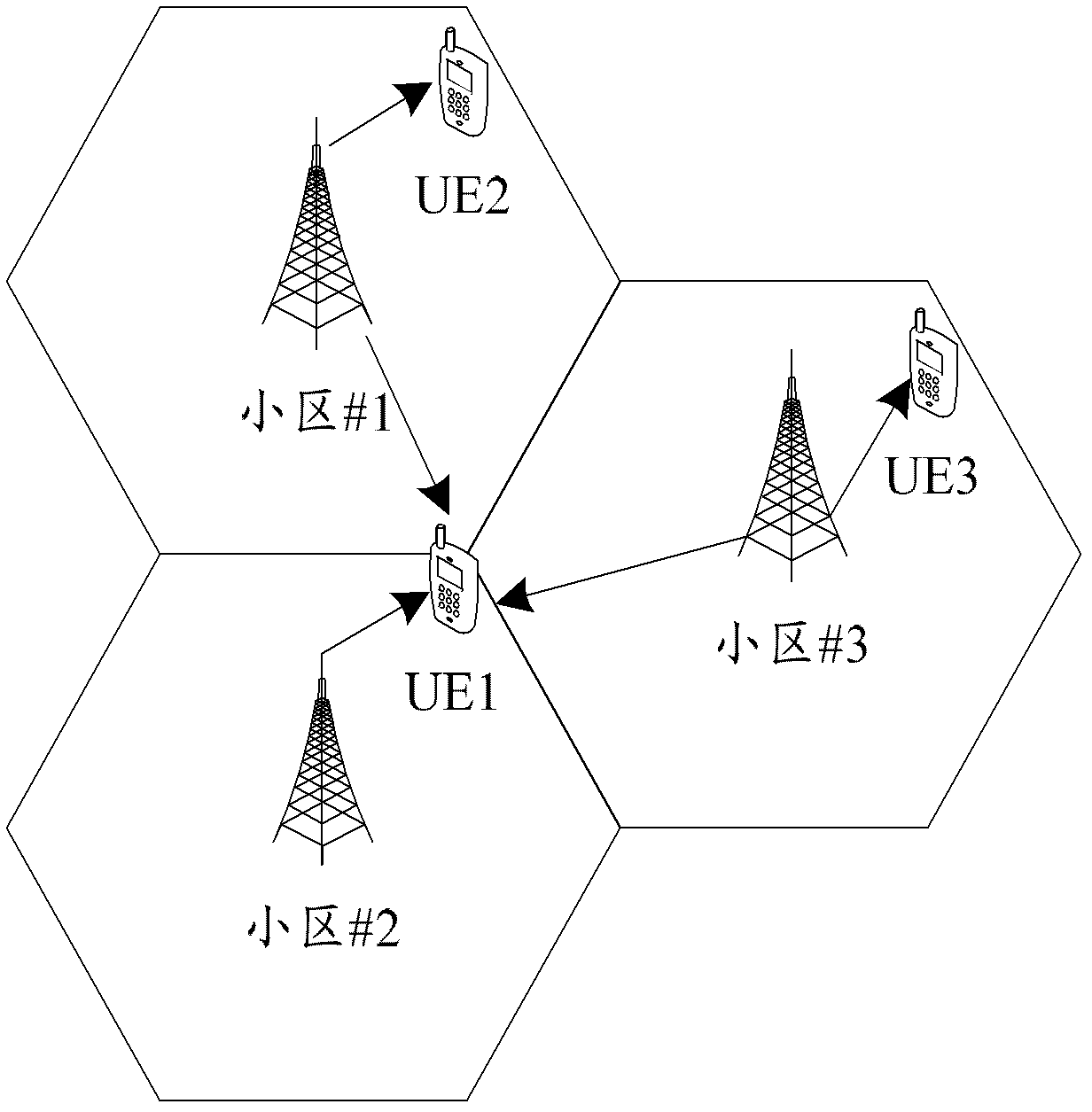

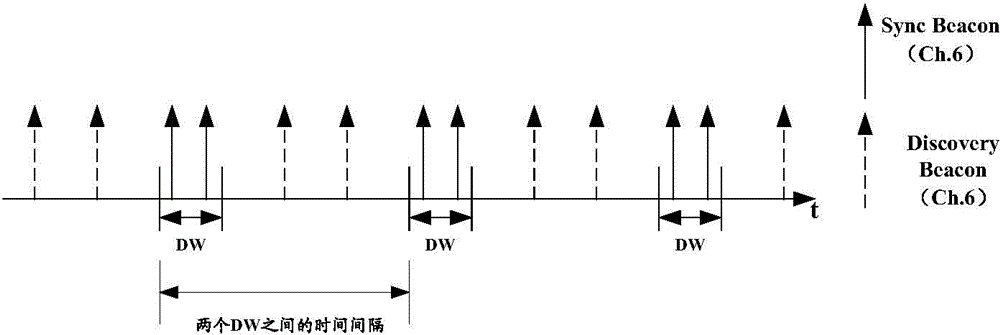

Disclosed are a method, device and system for joining a Neighbor Awareness Network (NAN) cluster. When a wireless device in a first NAN cluster scans and finds a second NAN cluster, if joining the second NAN cluster is necessary, then the wireless device leaves the first NAN cluster and joins the second NAN cluster; as the wireless device does not join a plurality of NAN clusters at the same time, the wireless device has low power consumption; in addition, as times goes on, when all the wireless devices in the first NAN cluster leave the first NAN cluster and join the second NAN cluster, the discovery window (DW) of the first NAN cluster on the working channel will not be occupied, thus increasing available resources on the working channel.

Owner:HUAWEI DEVICE CO LTD

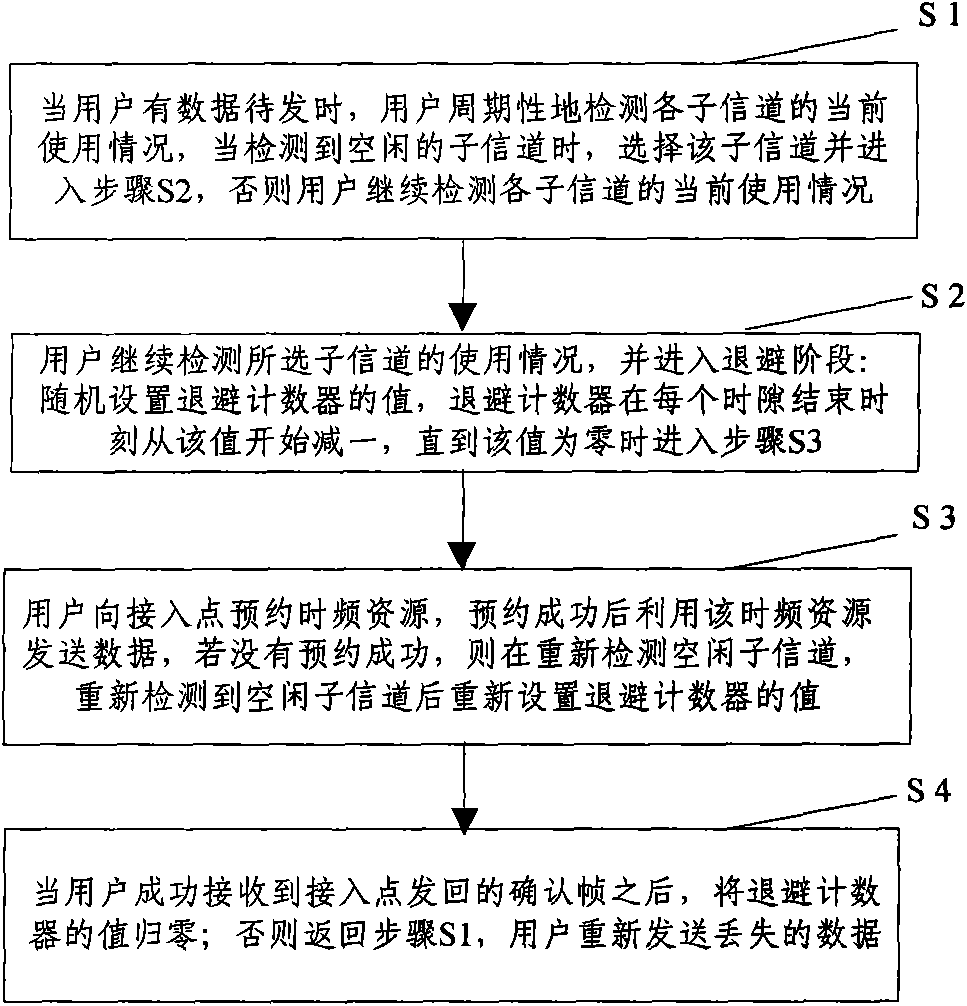

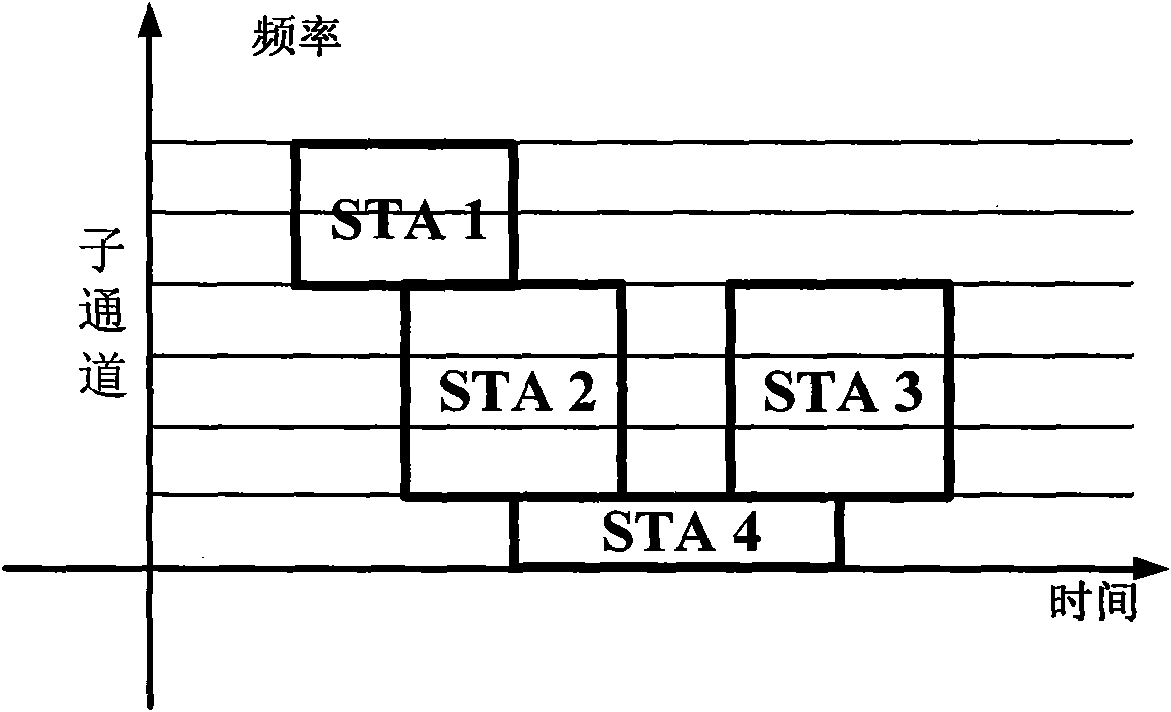

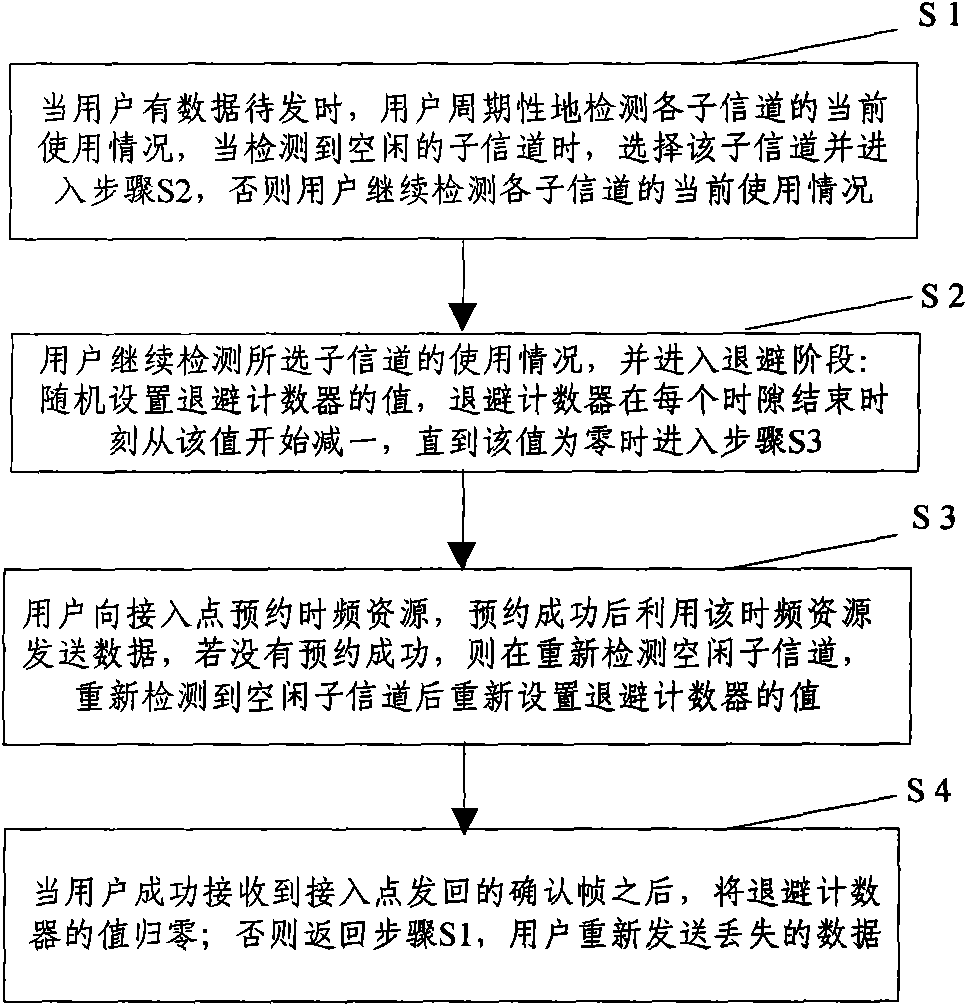

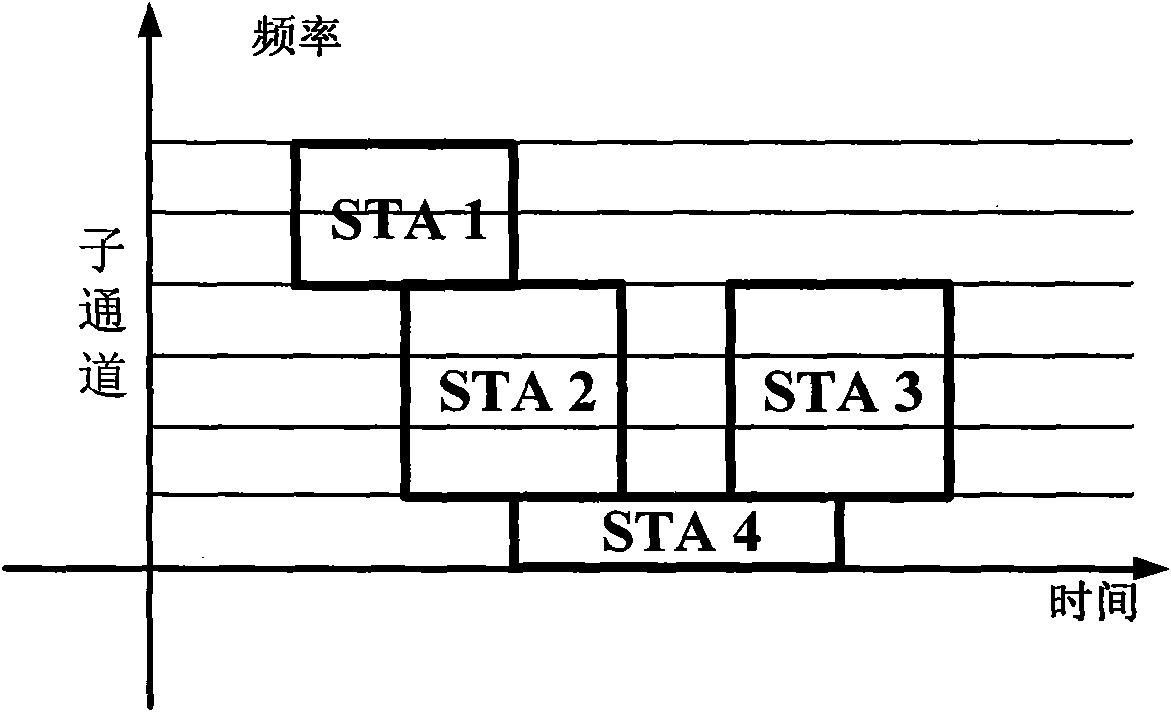

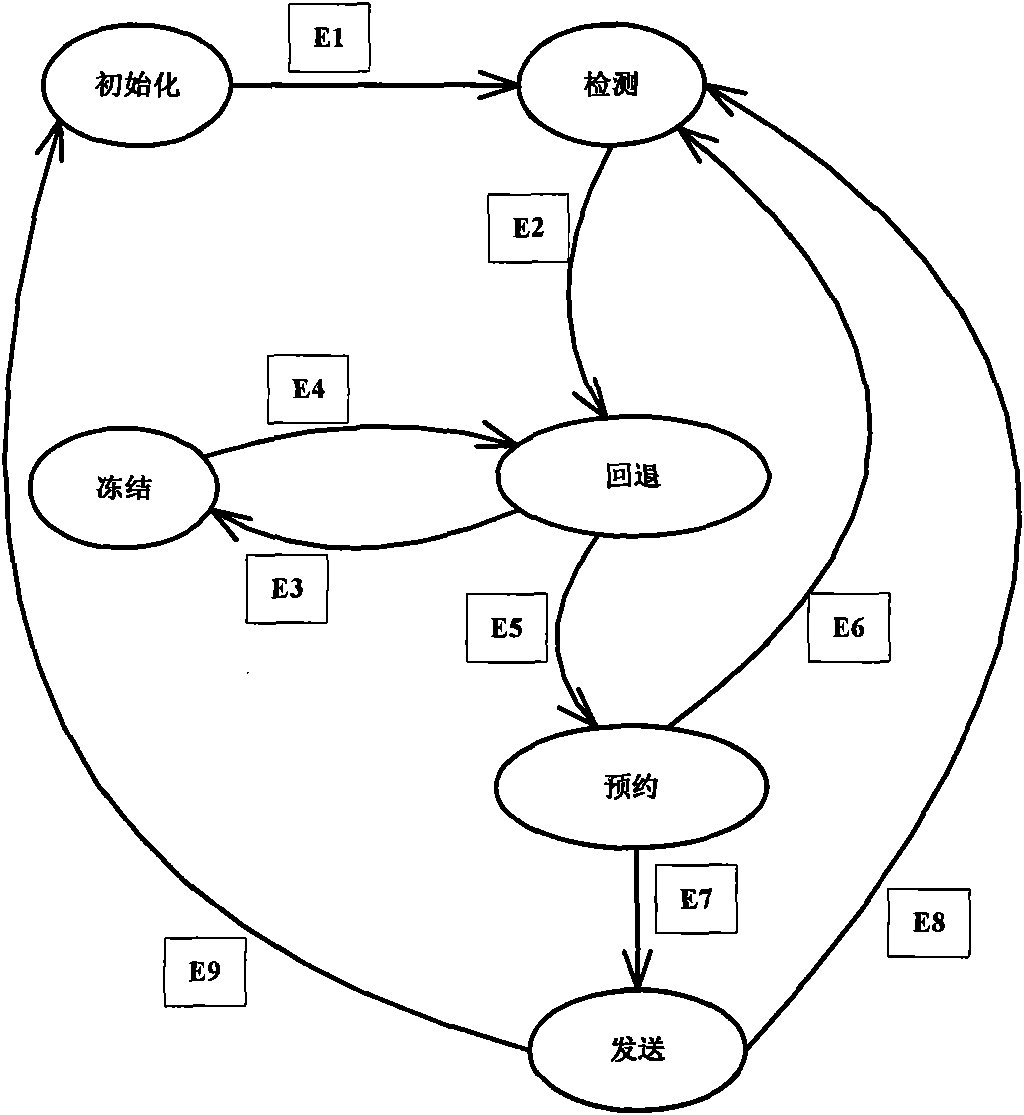

Time frequency two-dimensional hybrid MAC layer access method

InactiveCN102076106AIncrease chance of random accessIncrease available resourcesWireless communicationTime domainAccess method

The invention discloses a time frequency two-dimensional hybrid media access control (MAC) layer access method. In the two-dimensional direction of a frequency domain and a time domain, multiple users can compete with an available resource together, wherein the available resource comprises each sub channel and different time slots. Conflict is avoided by adopting a withdrawal mechanism, and the users are accessed to a wireless channel to transmit data by competing with the available resource and combining a reservation mechanism. The frequency resource and the time resource are simultaneously utilized in the method, and the competition and the reservation mechanism are combined, so that the utilization rate of the system channel is improved; and the conflict is avoided, so that the throughput of the whole system is effectively improved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

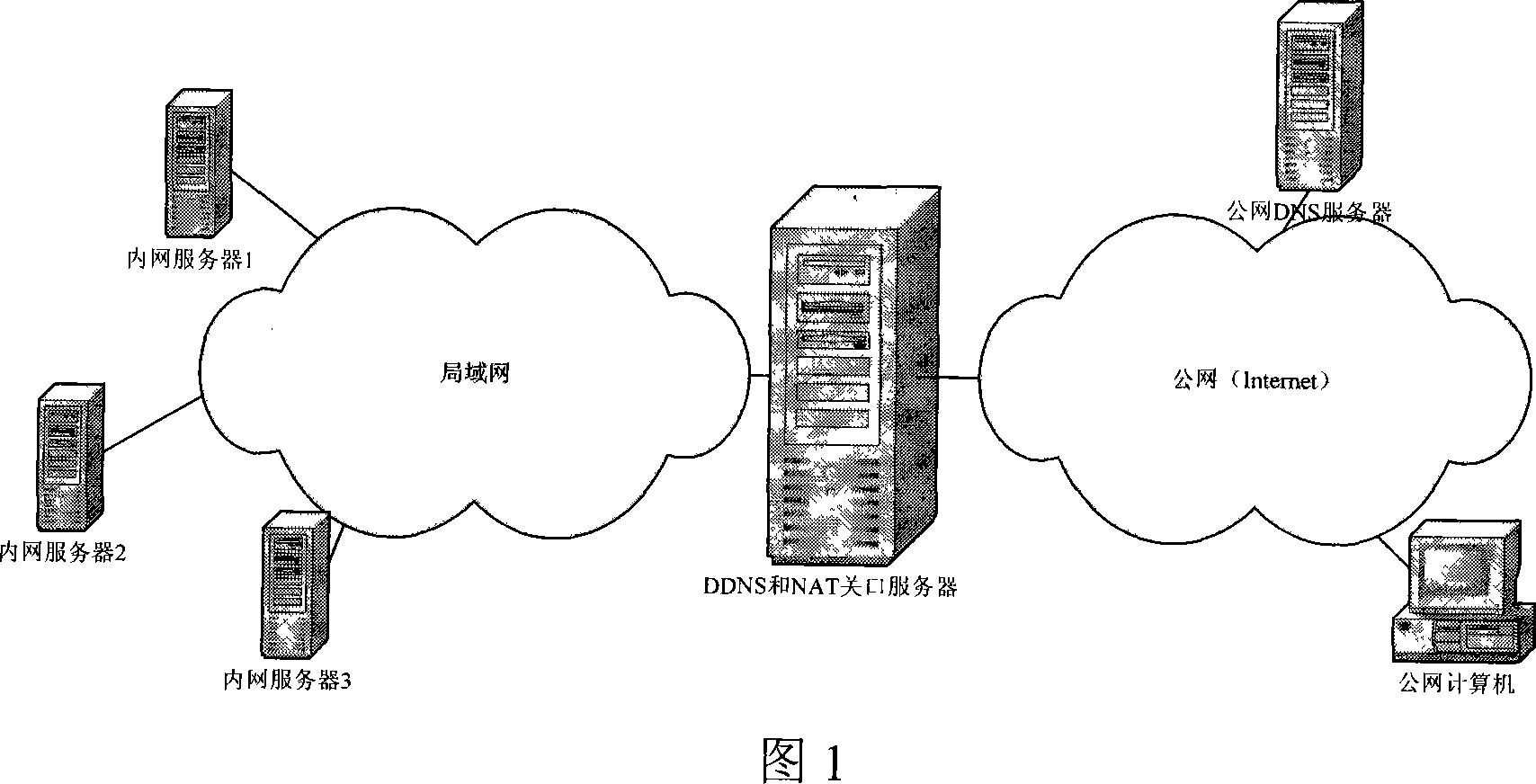

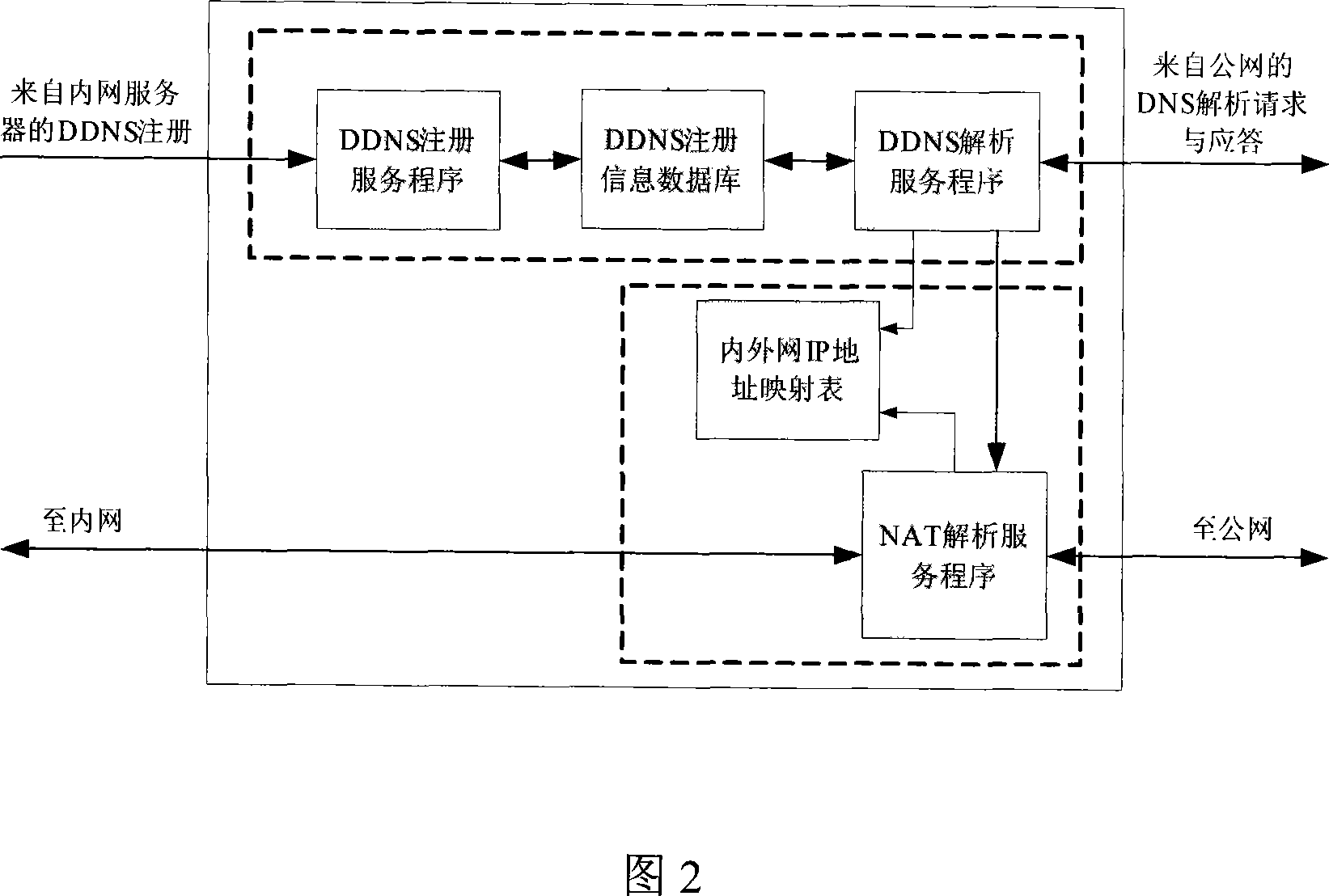

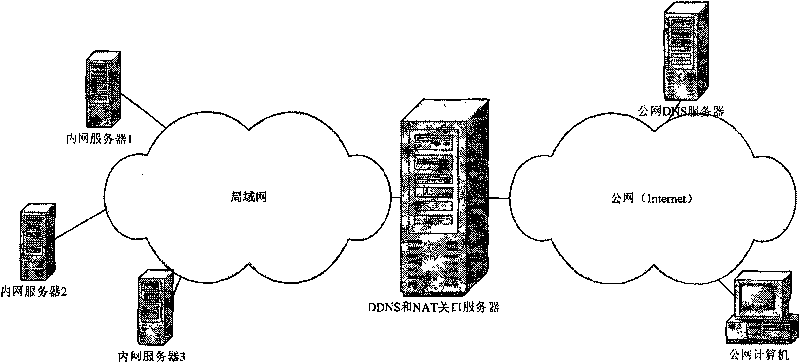

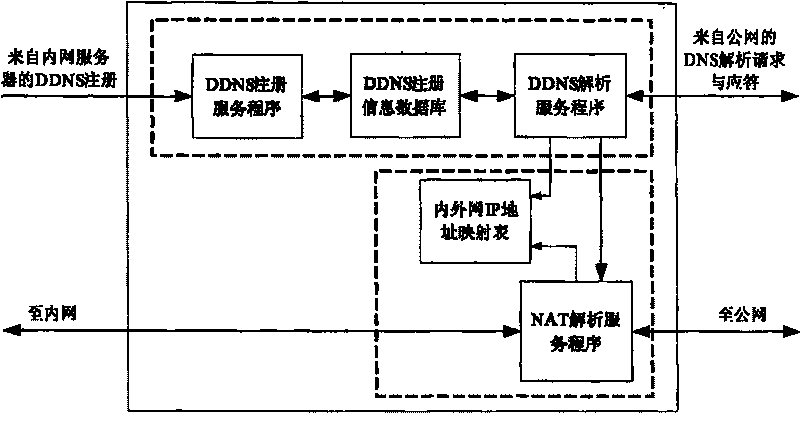

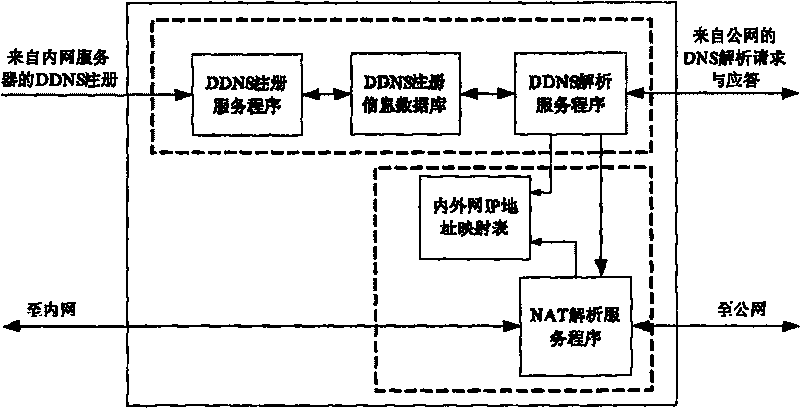

Method for mapping dynamically inside and outside network of server based on DDNS and NAT

InactiveCN101043447AFacilitate communicationImprove resource utilizationNetwork connectionsDomain nameIp address

The dynamic mapping method for internal and external server networks based on DDNS and NAT comprises: setting a special-developed internal-external gateway server or router, storing DDNS service program and the correlated NAT conversion service program; registering internal server DN and IP address message on the gateway server by NNDS client; to the DNS request for internal network server, using the NAT program to automatic allocate a public IP address; starting the NAT conversion to return the public IP address to complete the dynamic mapping.

Owner:CHONGQING UNIV +1

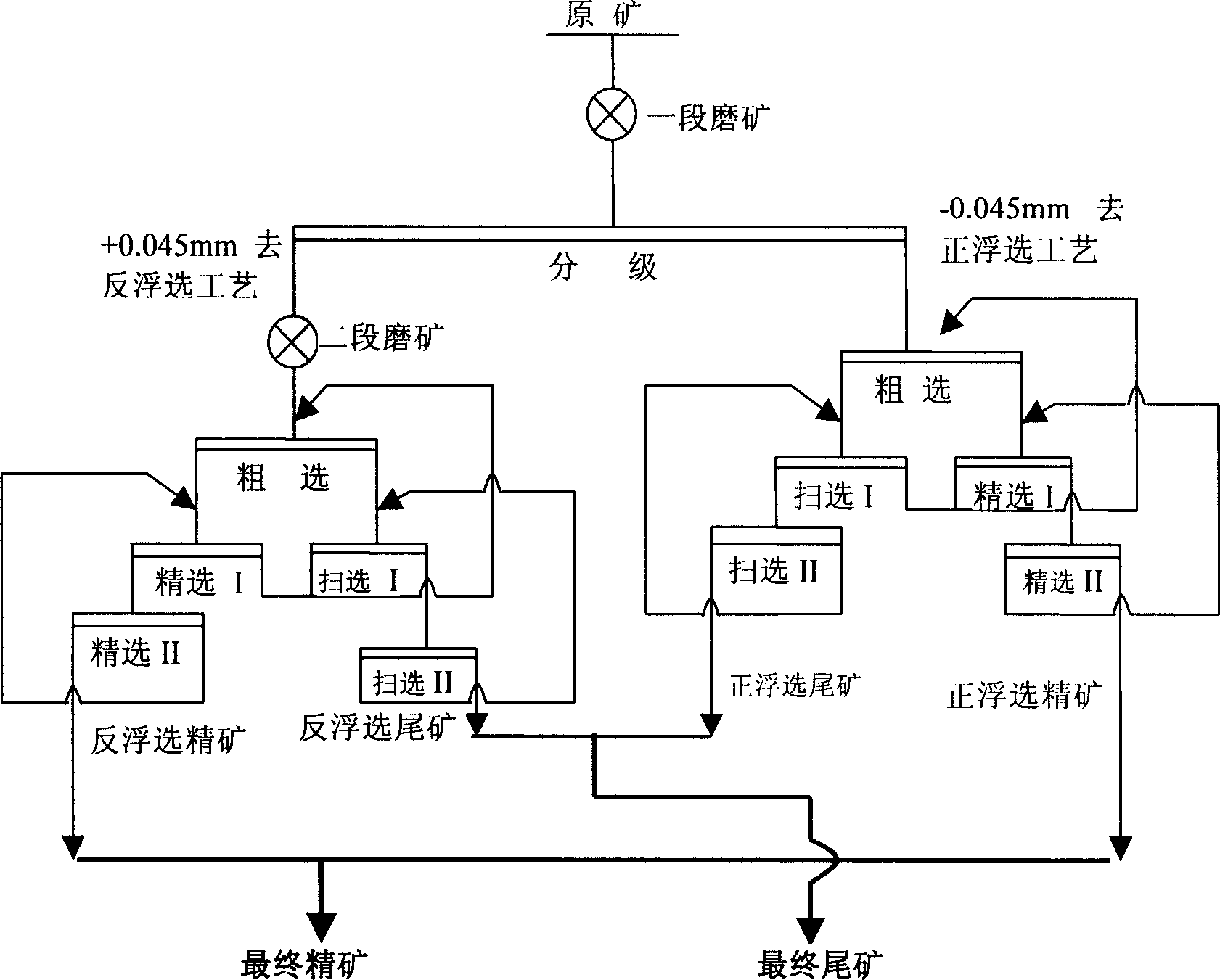

Parallel floatation process of desilionization for bauxite

InactiveCN1869258AEfficient separationIncrease production capacityFlotationProcess efficiency improvementEngineeringMaceral

The invention relates to a parallel floatation selecting method for bauxite desilication that adopts one section or two sections grinding technology to take classification to the bauxite pulp to gain raw and fine class product. The fine class product adopts positive floatation technology, and the raw class product adopts reverse floatation technology after taking or not taking second grinding. The positive floatation mine and the reverse floatation mine could be mixed to form final fine mine, and the positive floatation tail mine and the reverse floatation tail mine would be mixed to form final tail mine. The invention has great advantages and has wide application prospect.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

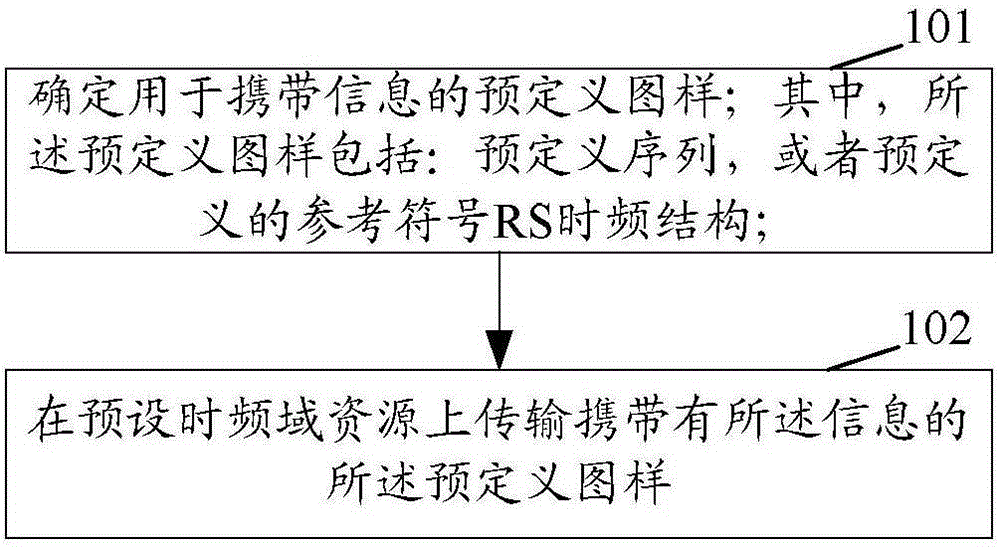

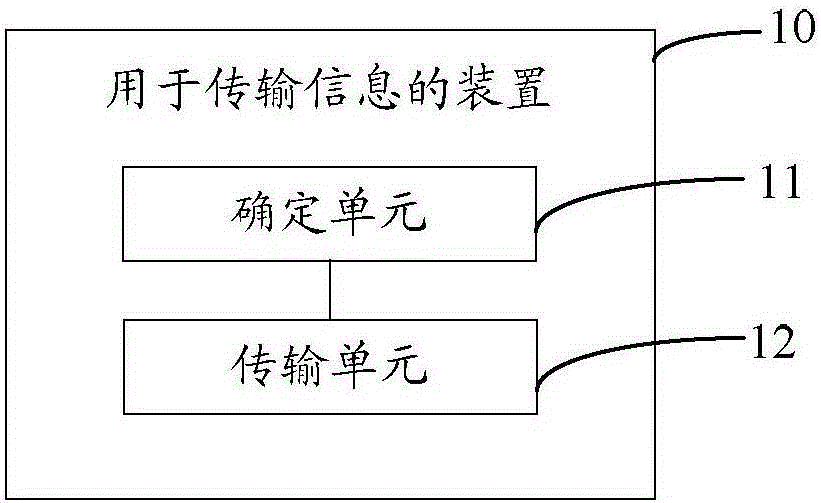

Information transmission method and device

ActiveCN106506127AImprove reliabilityIncrease available resourcesModulated-carrier systemsTransmission path divisionTelecommunicationsInformation transmission

The invention discloses an information transmission method and device. The method comprises the following steps: to begin, determining a predefined pattern for carrying information, wherein the predefined pattern comprises a predefined sequence, or a predefined reference symbol RS time-frequency structure; and then, transmitting the predefined pattern carried with the information in a preset time-frequency domain resource.

Owner:ZTE CORP

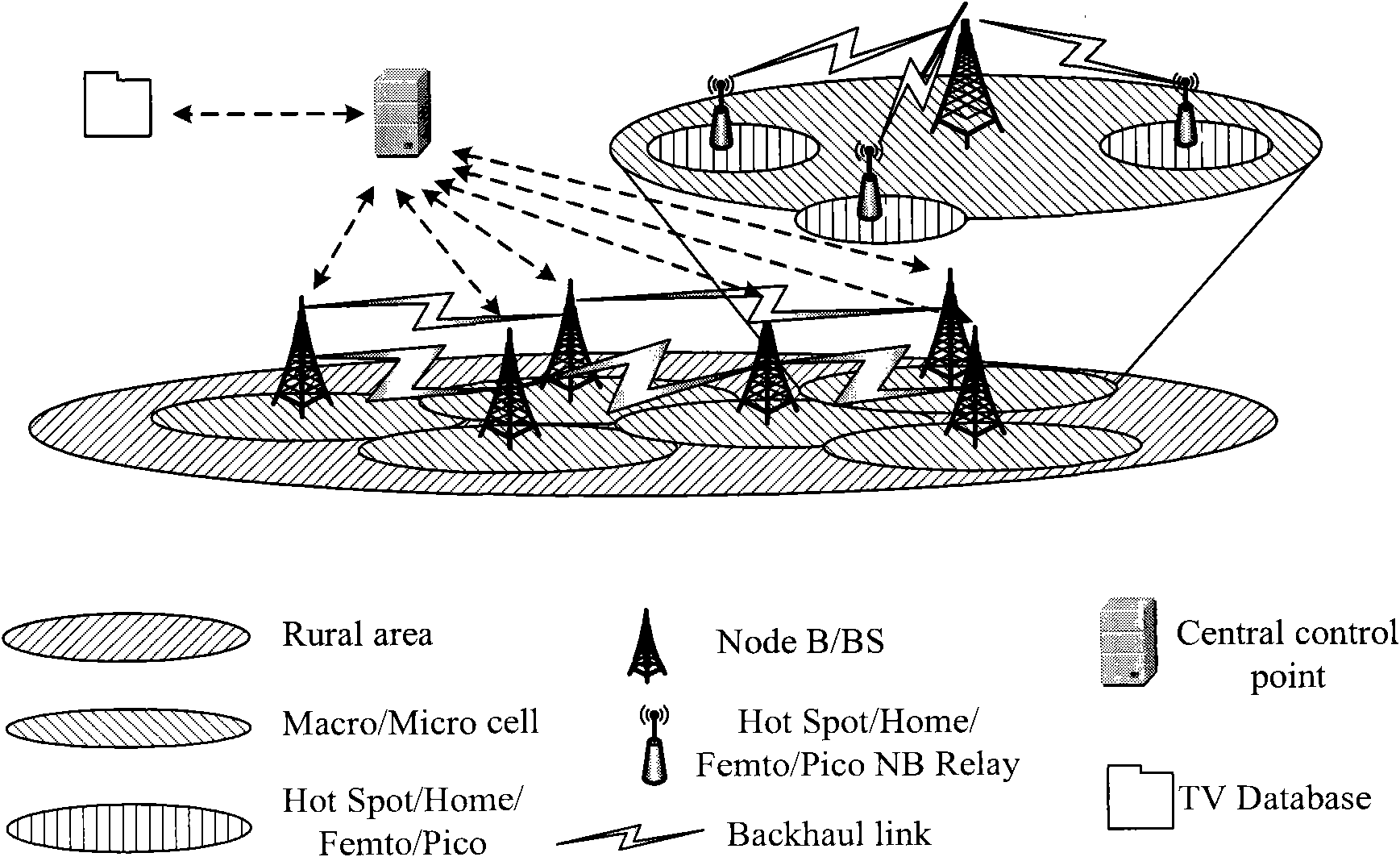

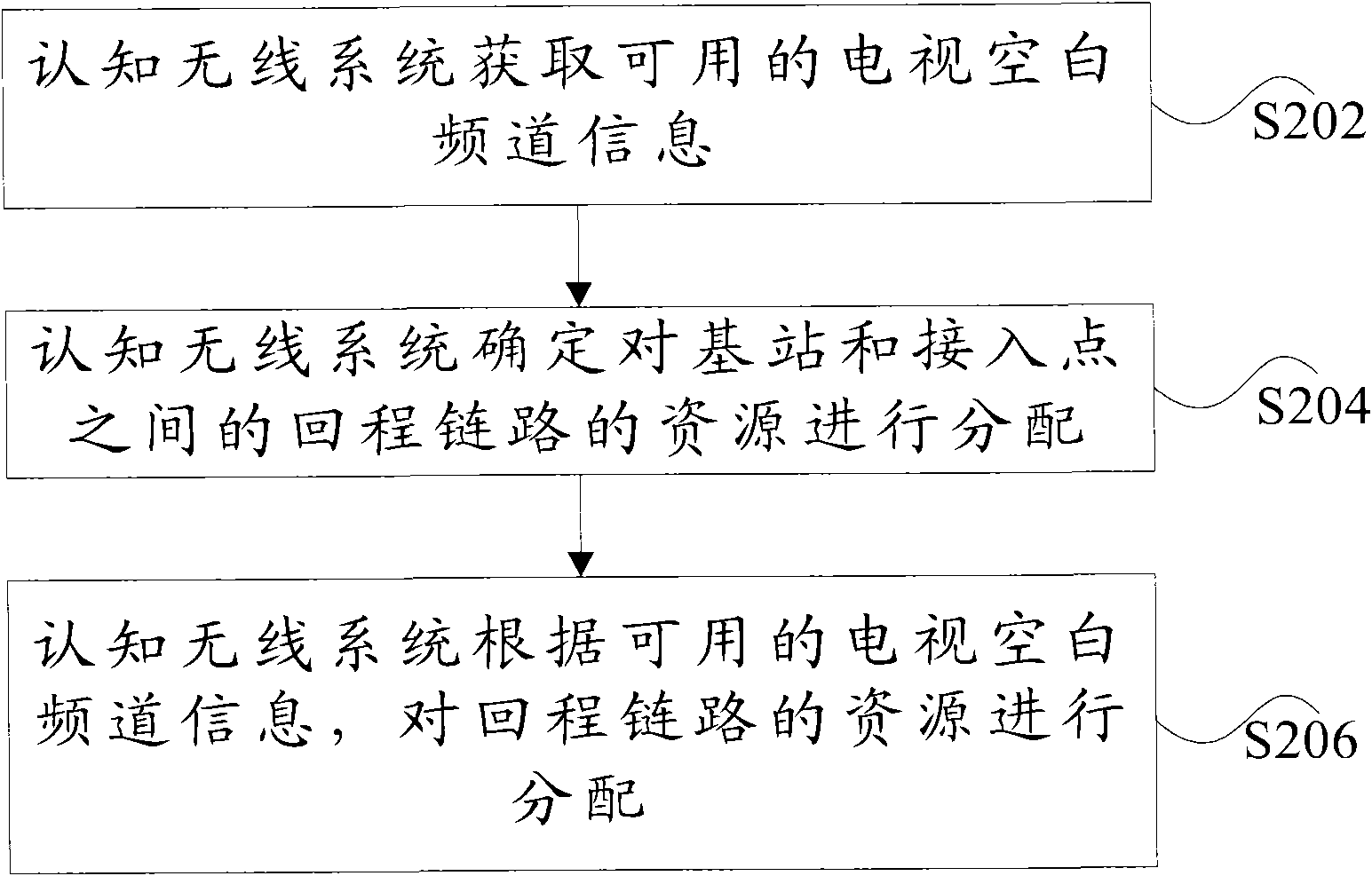

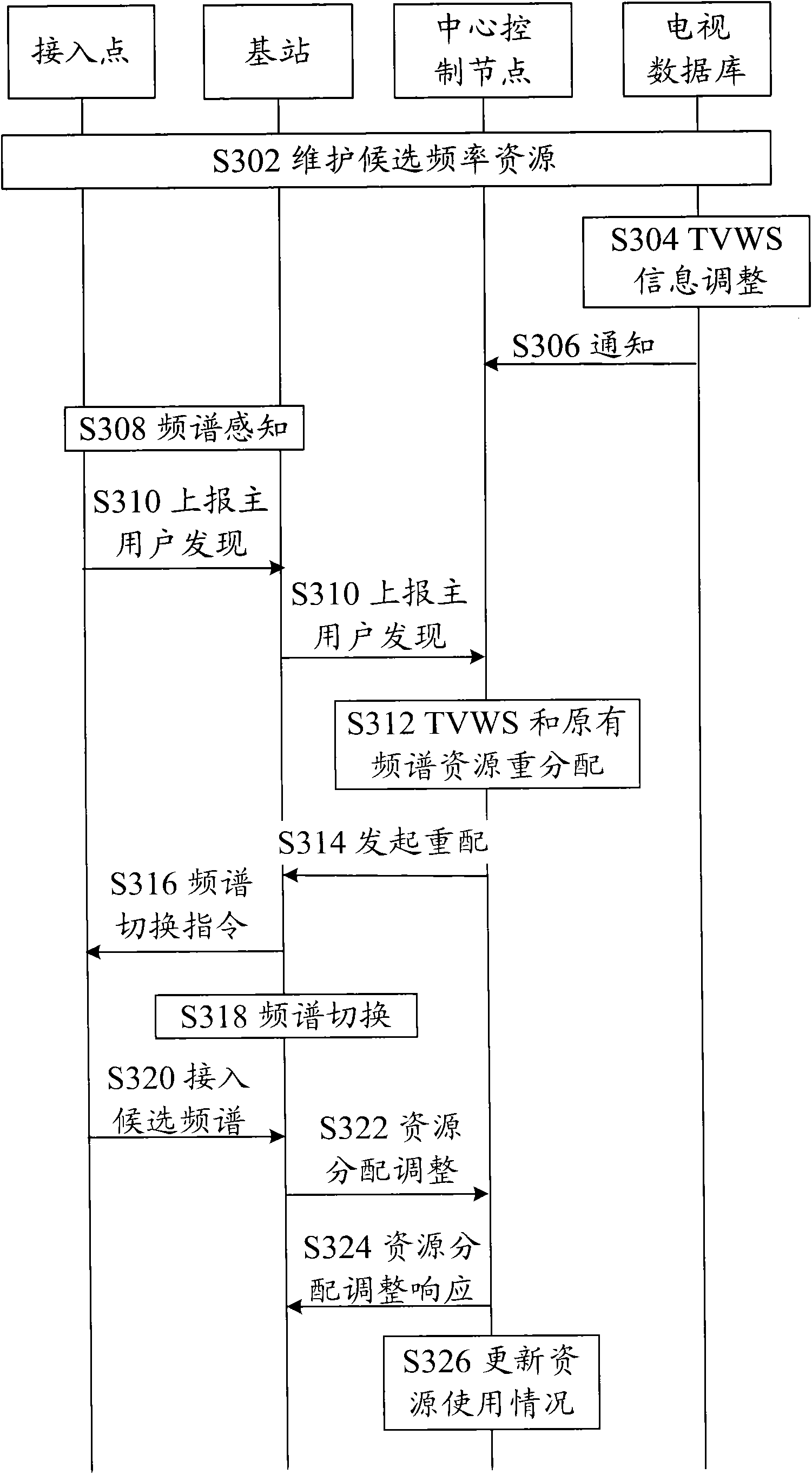

Resource allocation method and cognitive radio system

ActiveCN102387505AIncrease available resourcesSolve capacity problemsNetwork planningQuality of serviceResource allocation

The invention discloses a resource allocation method and system. The method comprises the following steps of: acquiring available television blank channel information by a cognitive radio system; determining the resource allocation of a backhaul link between the base station and an access point by the cognitive radio system; and allocating the resources of the backhaul link by the cognitive radio system according to the available television blank channel information. According to the method and system disclosed by the invention, the capacity and service quality of the backhaul link are guaranteed.

Owner:ZTE CORP

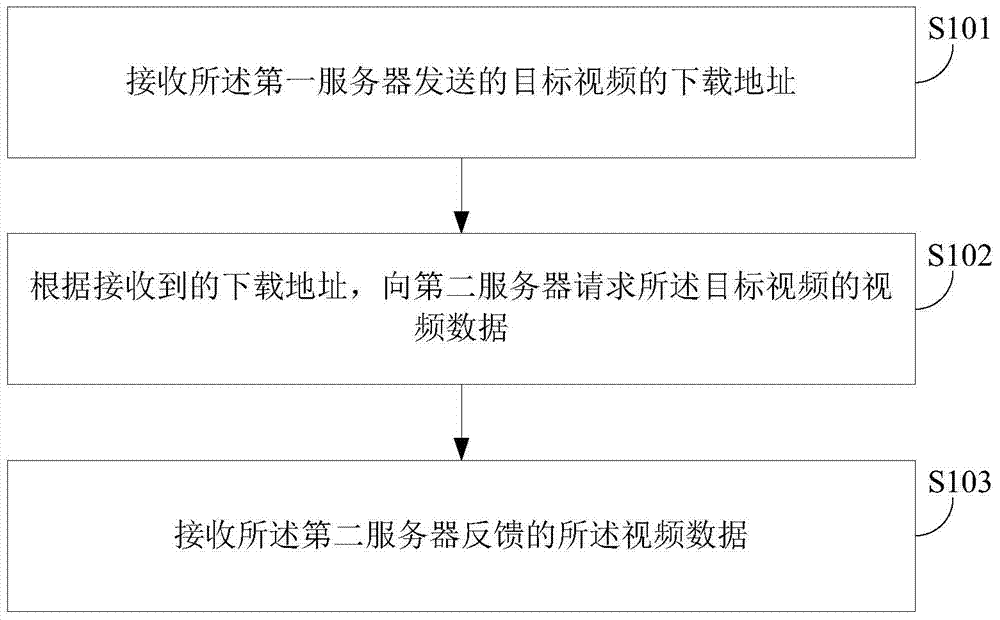

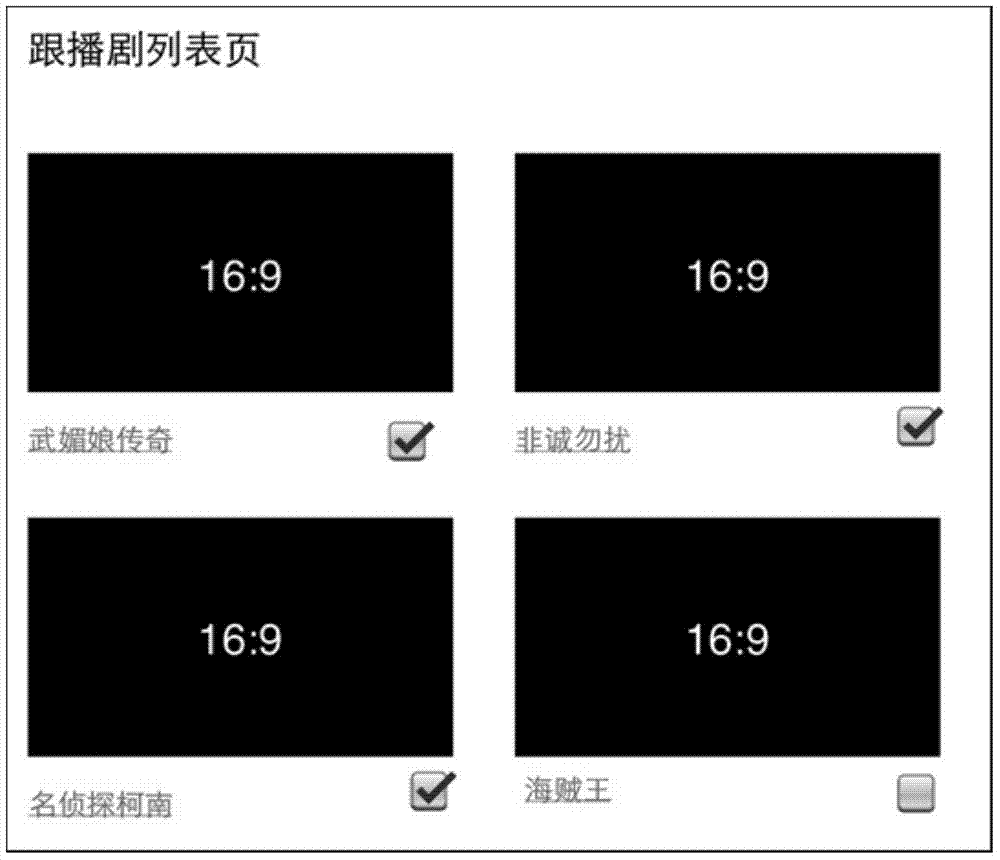

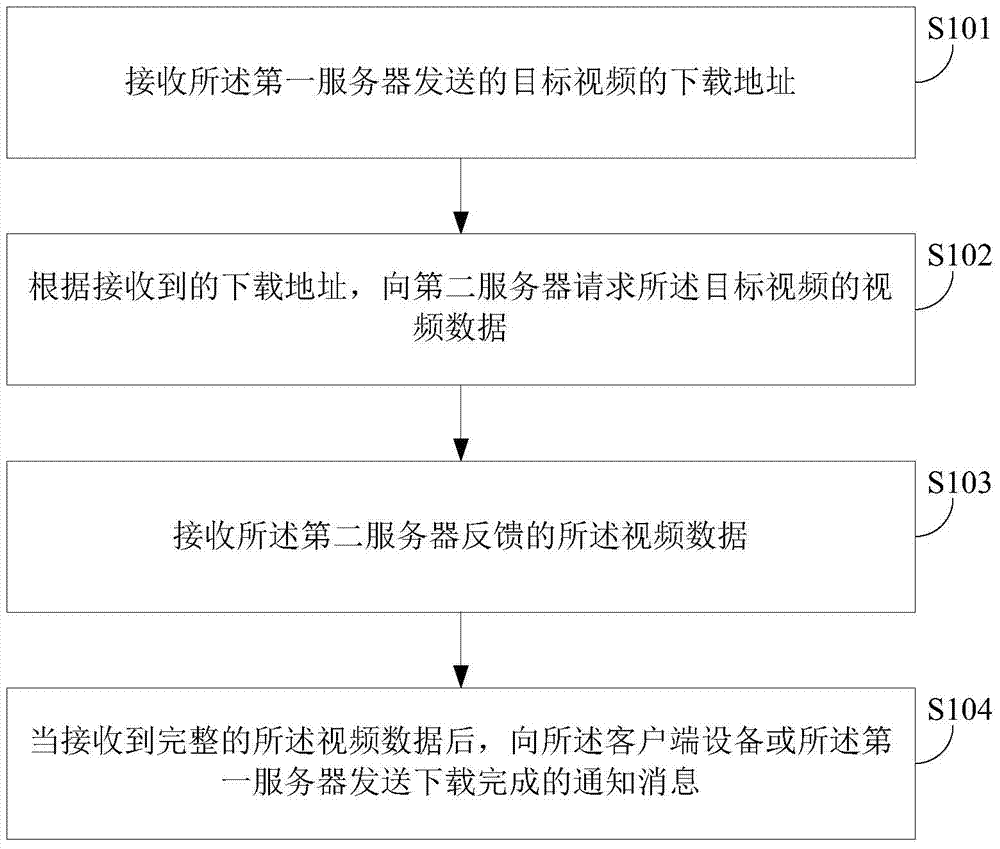

Video transmission method and video transmission device

InactiveCN104717527ASave powerReduce occupancySelective content distributionVideo transmissionClient-side

The invention discloses a video transmission method and a video transmission device, wherein the video transmission method is applied to a method of a router, the router is connected with a client device through an LAN (local area network) and is connected with a first server through a WAN (Wide Area Network), and the video transmission method comprises the following steps: receiving the download link of the target video sent by the first server, wherein the download link is searched by the first server according to a download request after the download request of the target video is sent to the first server by the client device, and the identity information of the client device and the router which have binding relationship is carried in the download request; requesting the video data of the target video from a second server according to the received download link; and receiving the video data which is fed back from the second server. According to the embodiment of the invention, the occupation of client device resources is reduced, and the electric quantity of the client device is saved.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

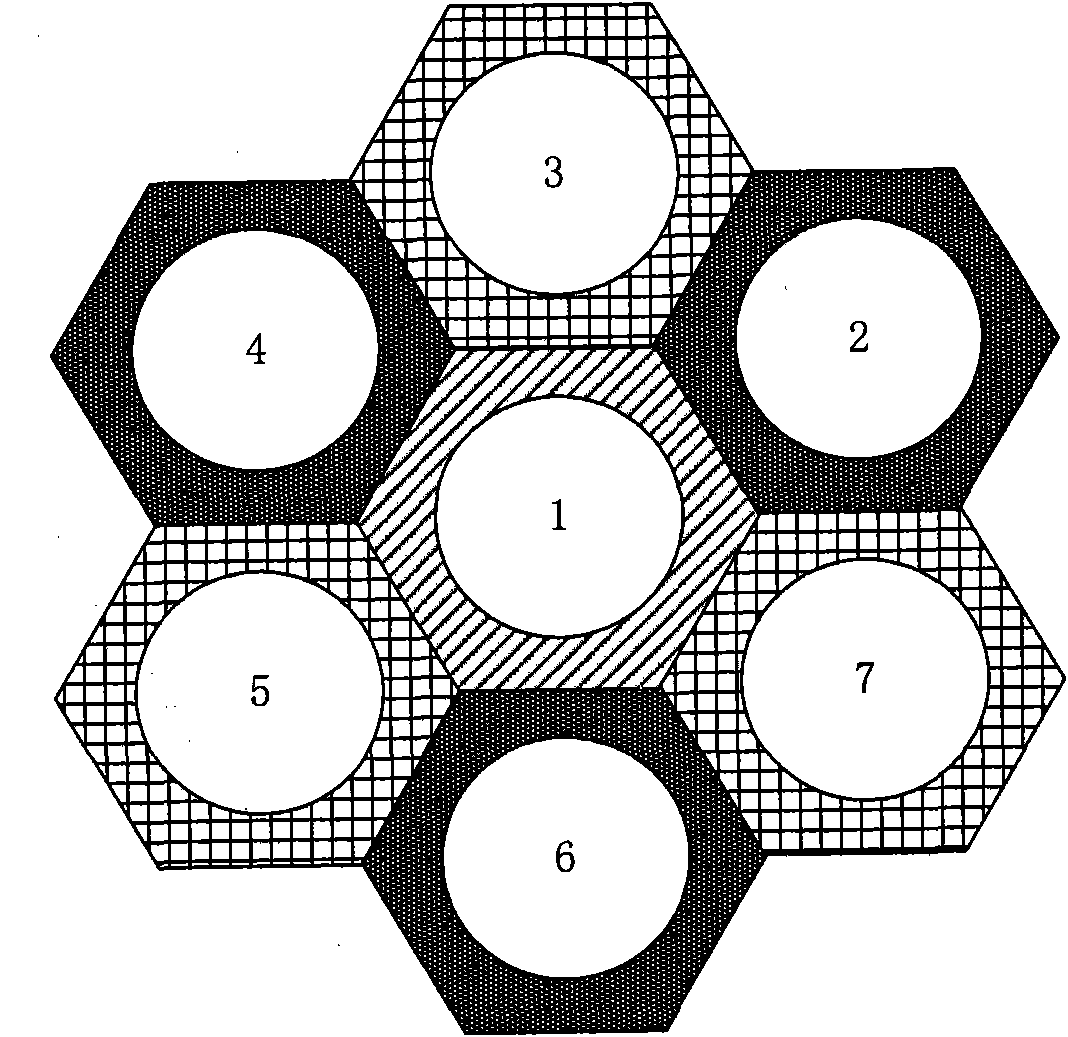

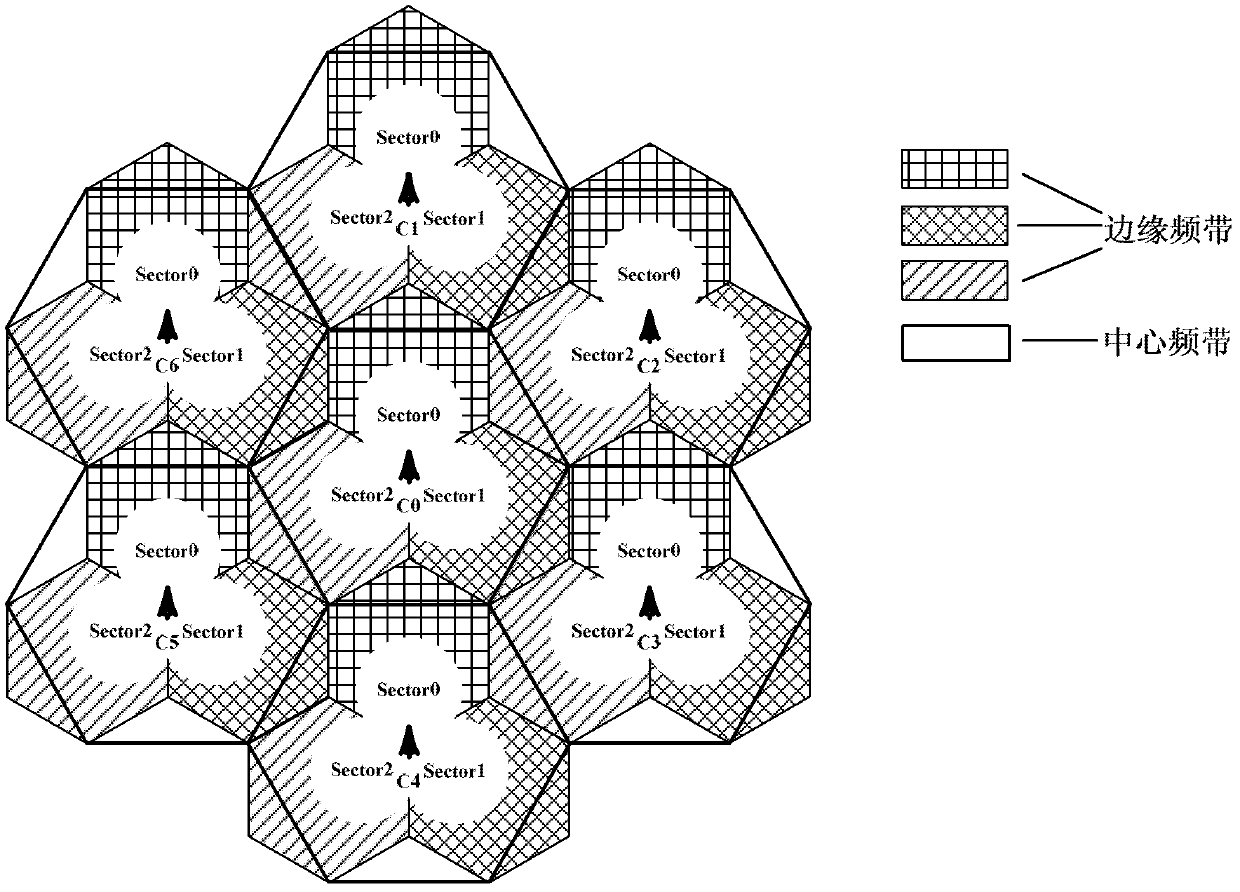

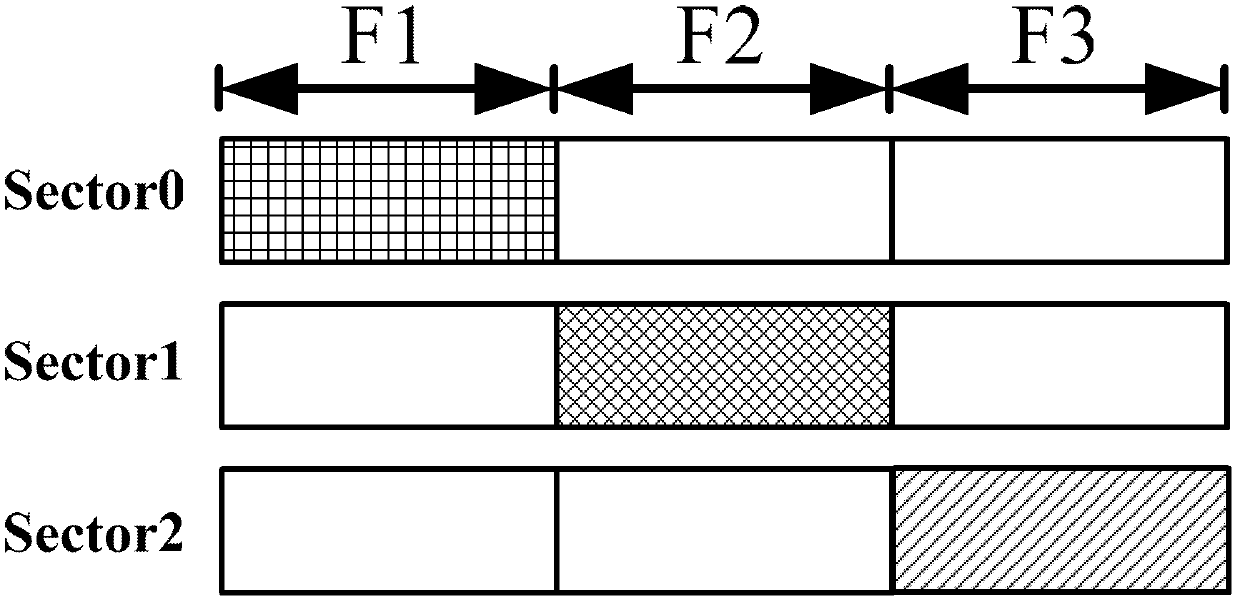

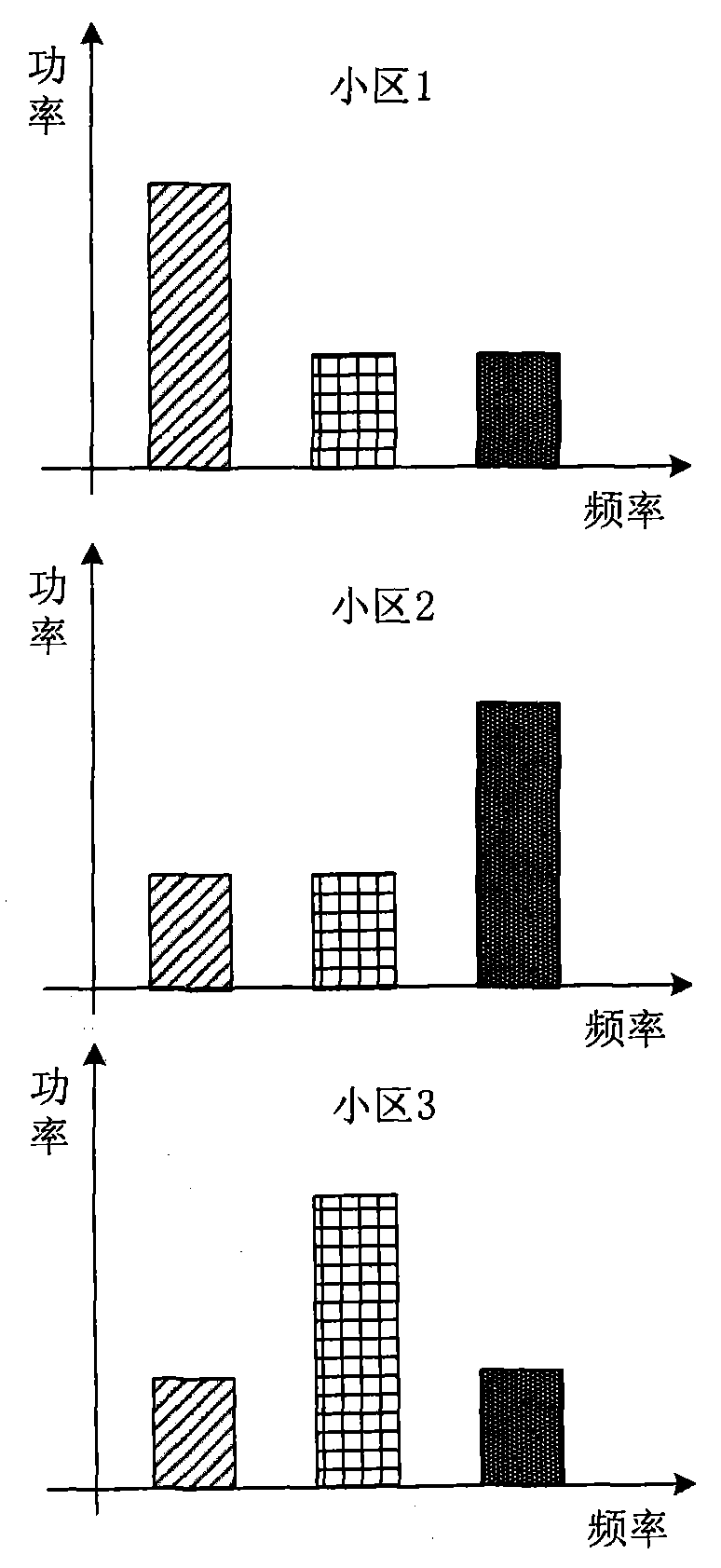

Soft spatial-frequency reuse method and apparatus thereof, and base station

ActiveCN102487372AImprove throughputThroughput minimizationError preventionMulti-frequency code systemsResource blockComputer science

The invention discloses a soft spatial-frequency reuse (SSFR) method and an apparatus thereof, and a base station. The method comprises the following steps that: according to intensity of a pilot signal feedbacked by a user, an area of a cell that the user is located at is determined as well as frequency resources that are available for the user are determined; according to the frequency resources that are available for the user, corresponded transmitting powers are distributed and resource scheduling is carried out; according to a resource scheduling result, group users are selected, wherein the group users include users that use the same physical resource block (PRB) as the user uses in the same cell and a neighboring cell; a minimum interference leakage matrix is obtained according to the group users as well as under the minimum interference leakage matrix, the interference of downlink data of the user on the set user is minimum, wherein the downlink data are sent by a serving base station of the cell that the user is located at; a precoding matrix of the user is obtained according to the minimum interference leakage matrix; and on the basis of the precoding matrix, precoding is carried out on the downlink data so as to obtain precoded data. According to the embodiment of the invention, on the condition that the total throughput of a cell is not reduced, the throughput of a cell edge area (CEA) is increased.

Owner:BEIJING UNIV OF POSTS & TELECOMM

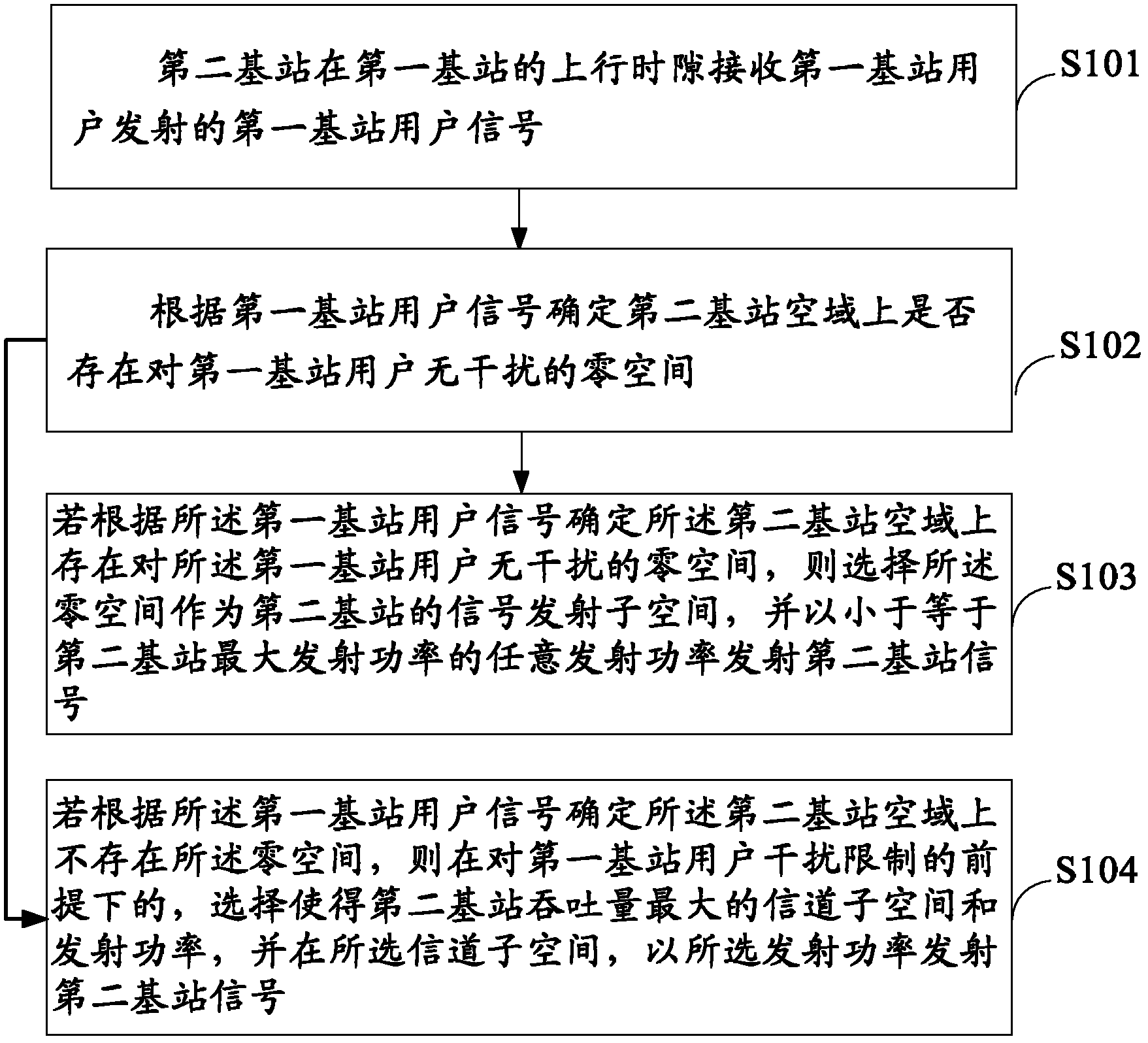

Method, device and system for frequency resource sharing

InactiveCN102404750AIncreased frequency sharing efficiencyAvoid interferenceNetwork planningFrequency sharingAir space

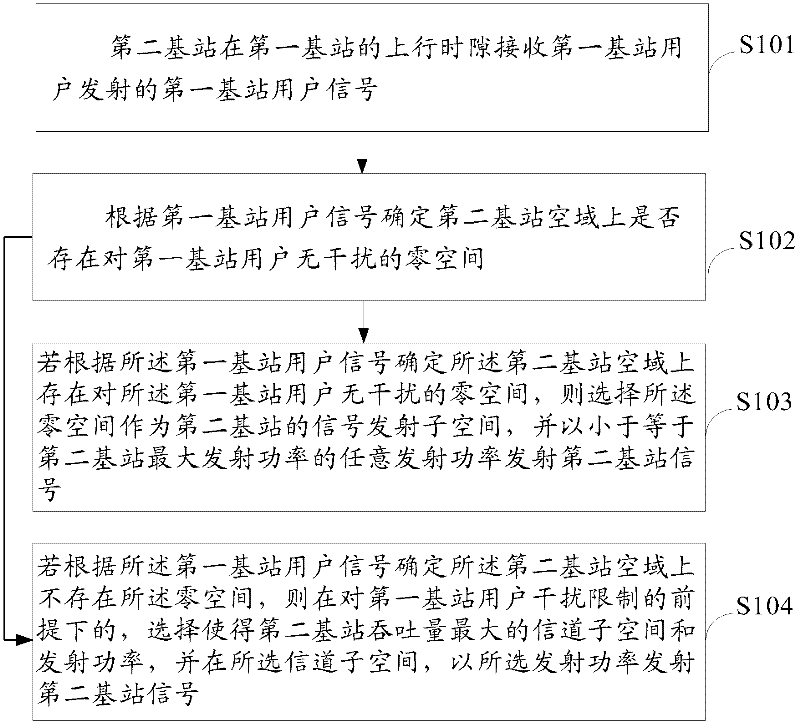

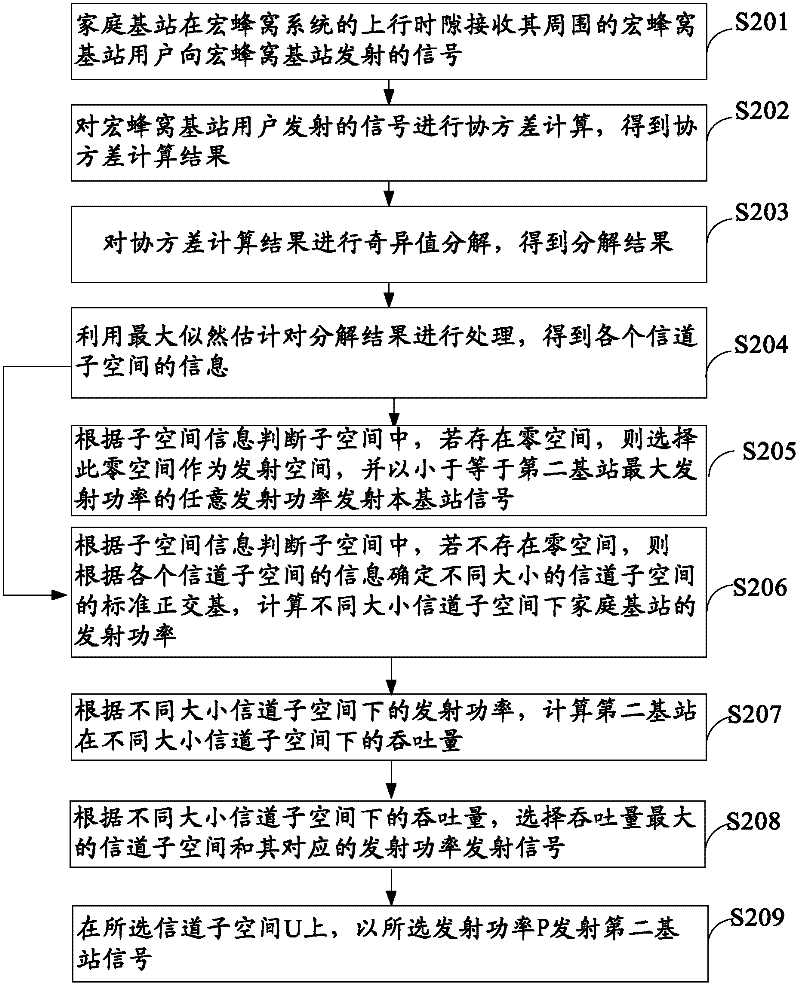

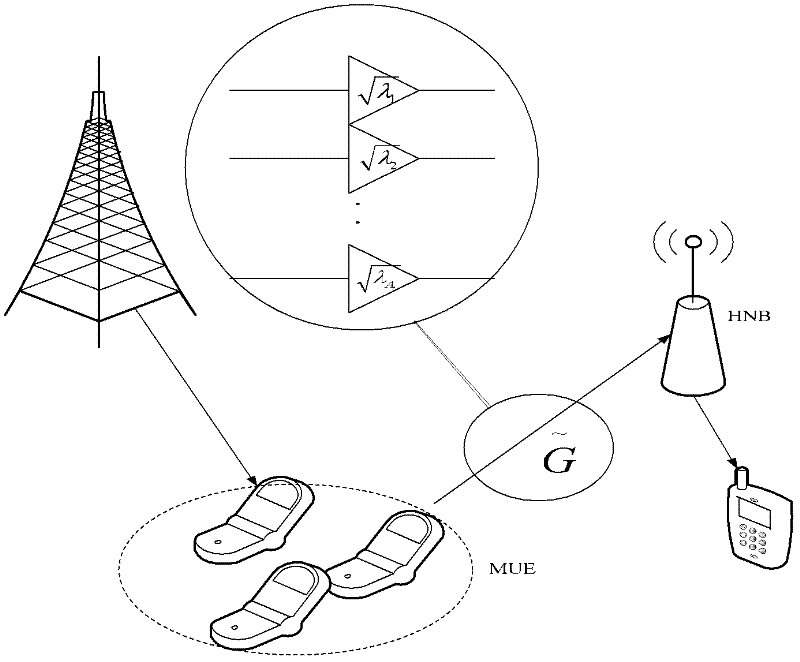

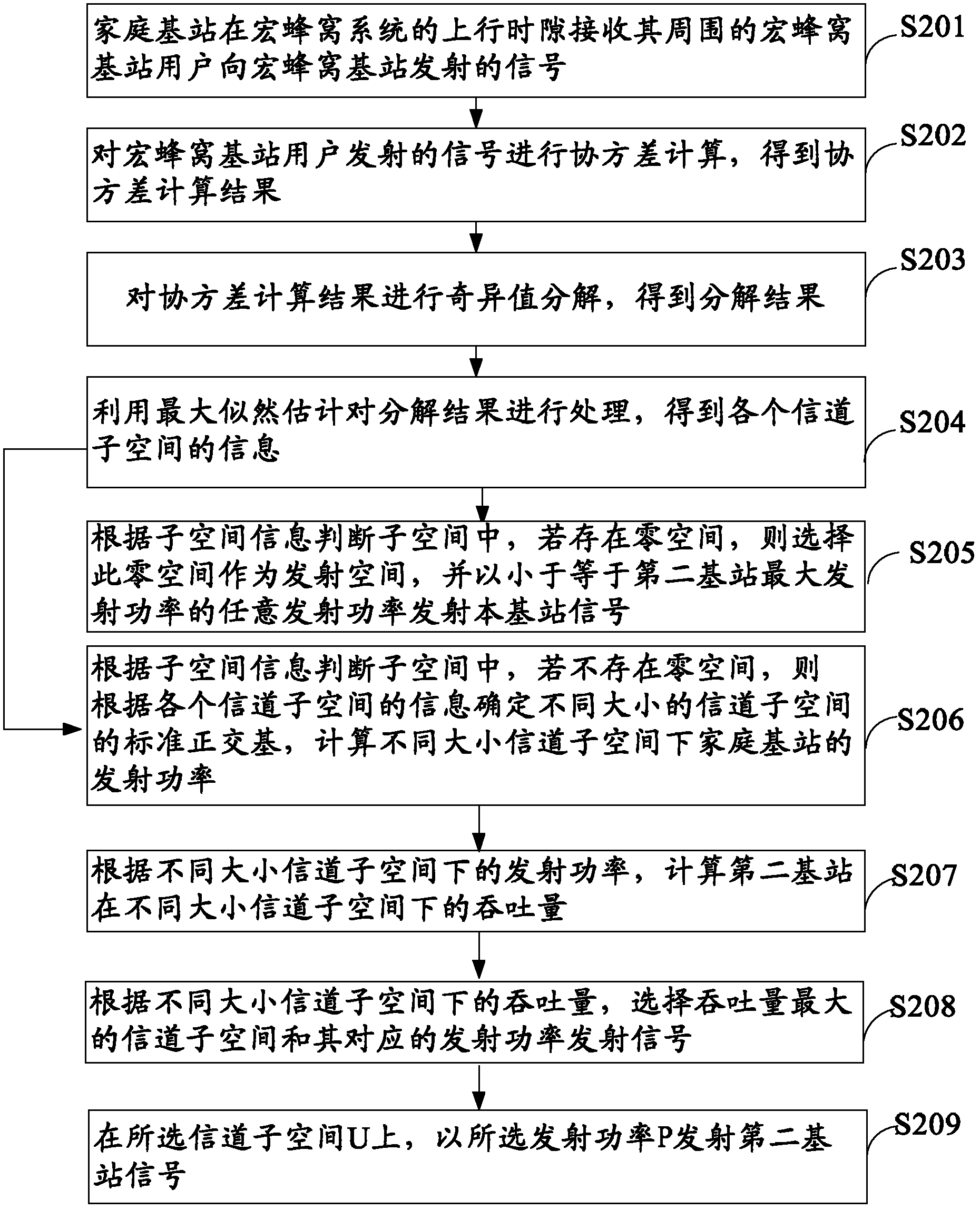

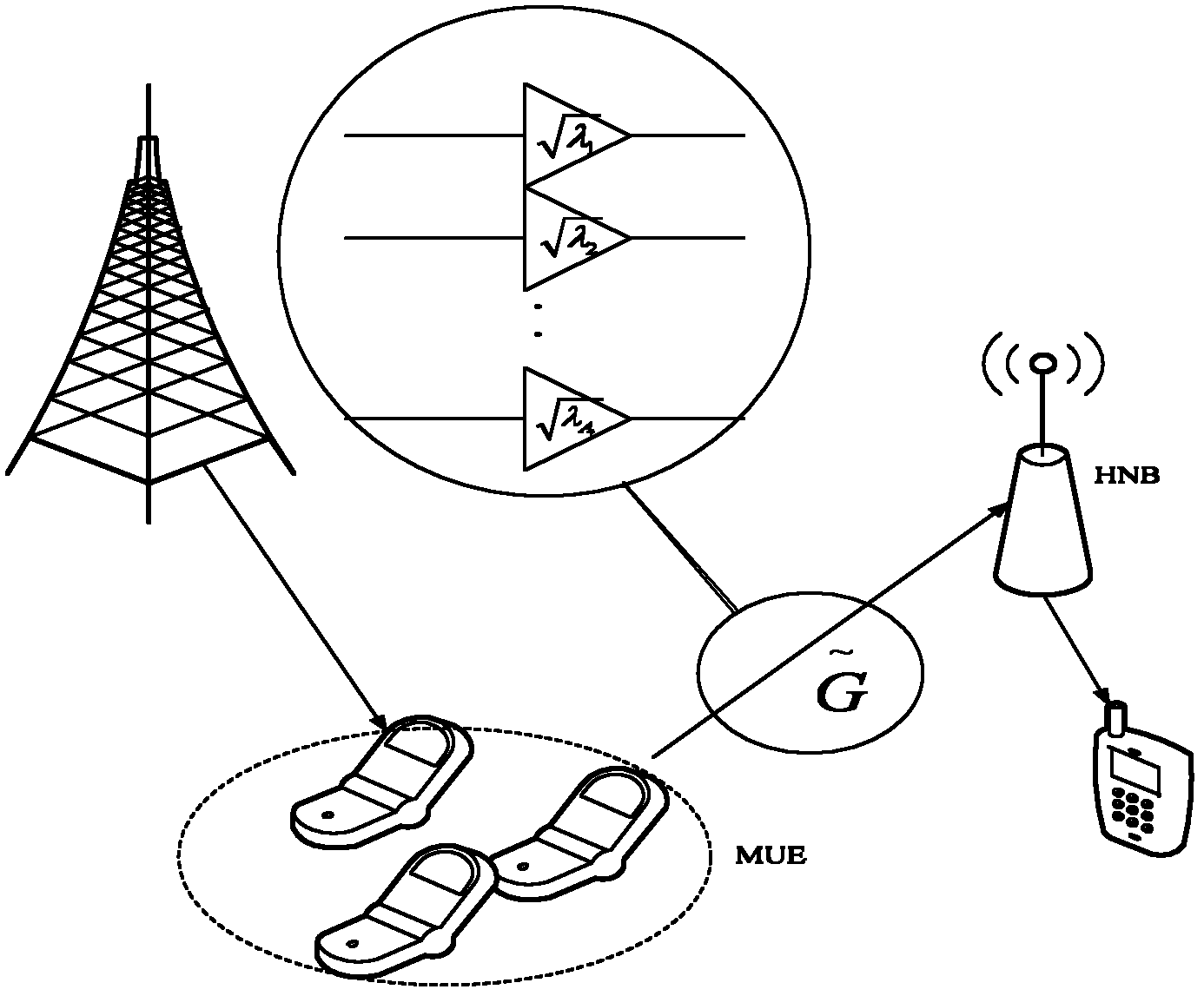

The embodiment of the invention provides a method, device and system for frequency resource sharing, relates to the field of communication, and is used for improving the frequency sharing efficiency between equipment. The method comprises the steps as follows: a second base station receives first base station user information sent by first base station users; whether null space having no interference with first station users exists in the airspace of the second base station or not is determined according to the first base station user information; if the fact that null space having no interference with first station users exists in the airspace of the second base station is determined, the null space is used as a signal emission subspace of the second base station, and the second base station signals are transmitted with any transmission power less than or equal to the greatest transmission power of the second base station; if no existence of null space in the airspace of the second base station is determined, under the premise of interference and restriction on the first base station users, a signal channel subspace and the transmission power which enable the throughput of the second base station to be the most are chosen, and the second base station signals are transmitted with the chosen the transmission power in the chosen signal channel subspace.

Owner:李春秀

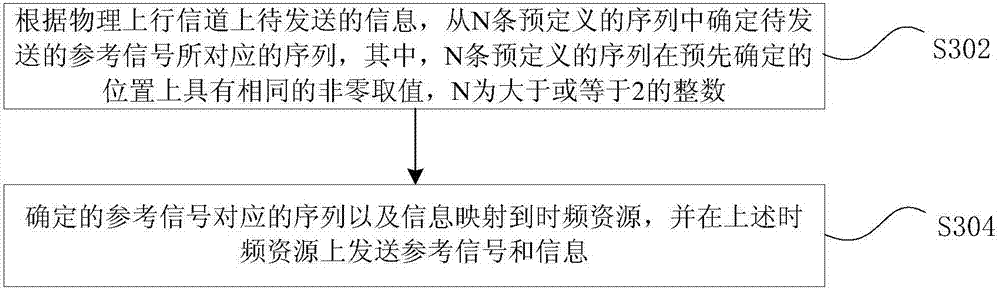

Information sending method and device

ActiveCN107231690AIncrease available resourcesMulti-frequency code systemsWireless communicationComputer scienceInformation mapping

The invention provides an information sending method and device. The method comprises the steps of determining a sequence corresponding to a to-be-sent reference signal from N predefined sequences according to to-be-sent information on a physical uplink channel, wherein the N predefined sequences have the same nonzero value at predetermined positions, and the N is an integer greater than or equal to 2; and mapping the sequence corresponding to the determined reference signal and the information to time frequency resources and sending the reference signal and the information on the time frequency resources. Through adoption of the technical scheme, the problem that in related technologies, the available resources for sending valid data (interpreted as the to-be-sent information on the physical uplink channel) on the physical uplink channel is reduced due to the fact that the number of TTI (Transmission Time Interval) symbols is reduced and the cost of the reference signal is increased is solved, and the available resources for transmitting the valid data are further improved.

Owner:ZTE CORP

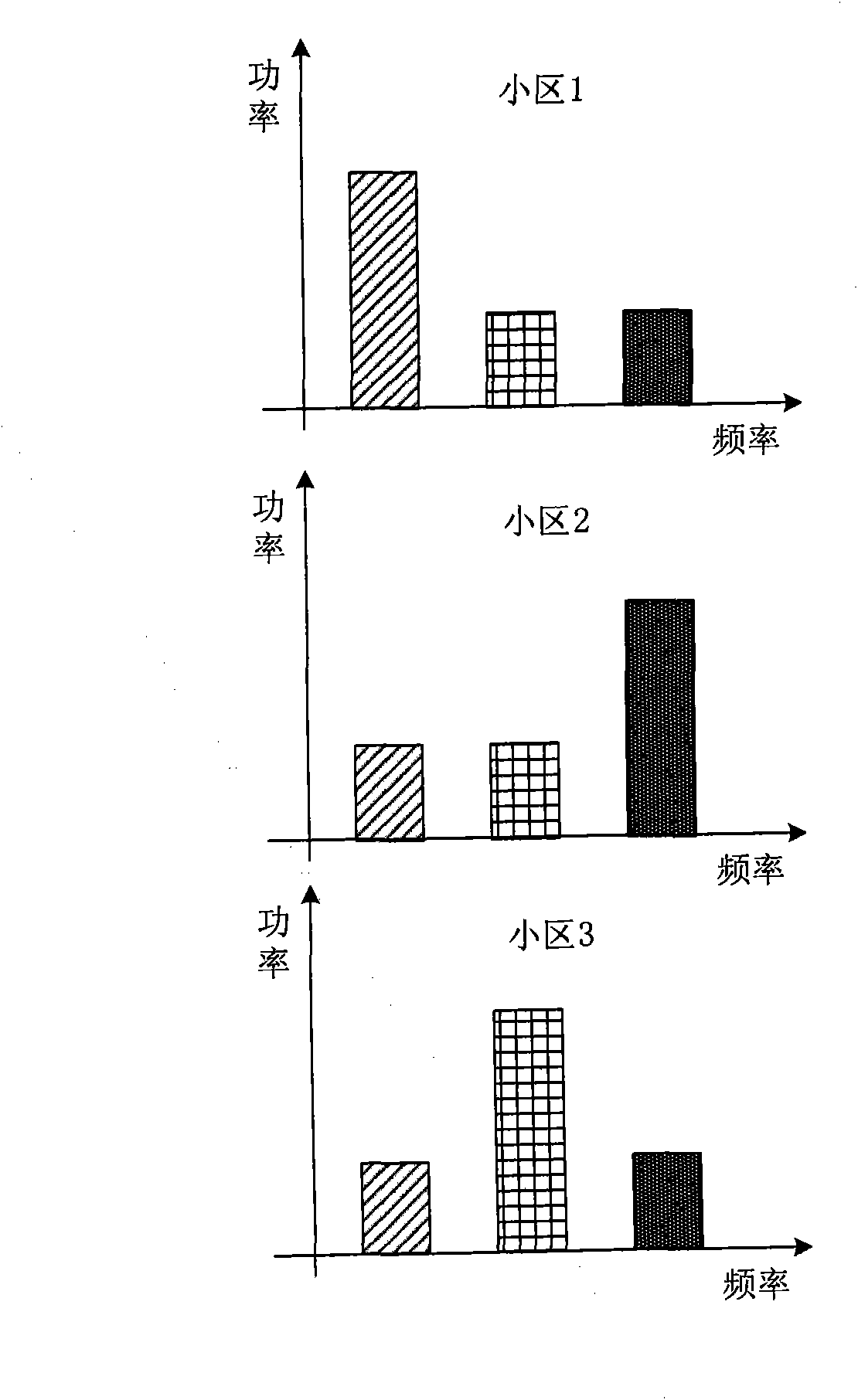

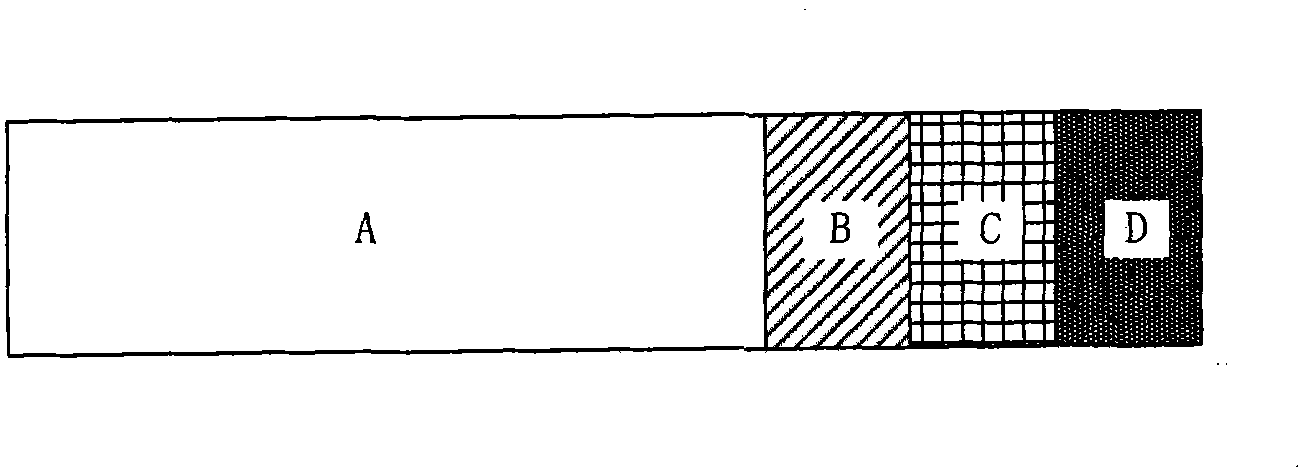

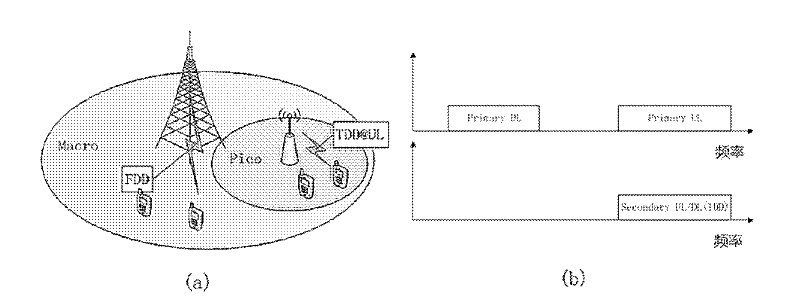

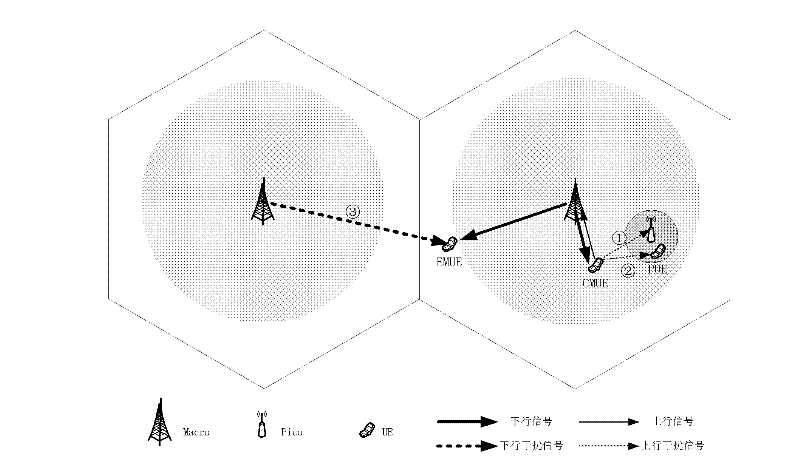

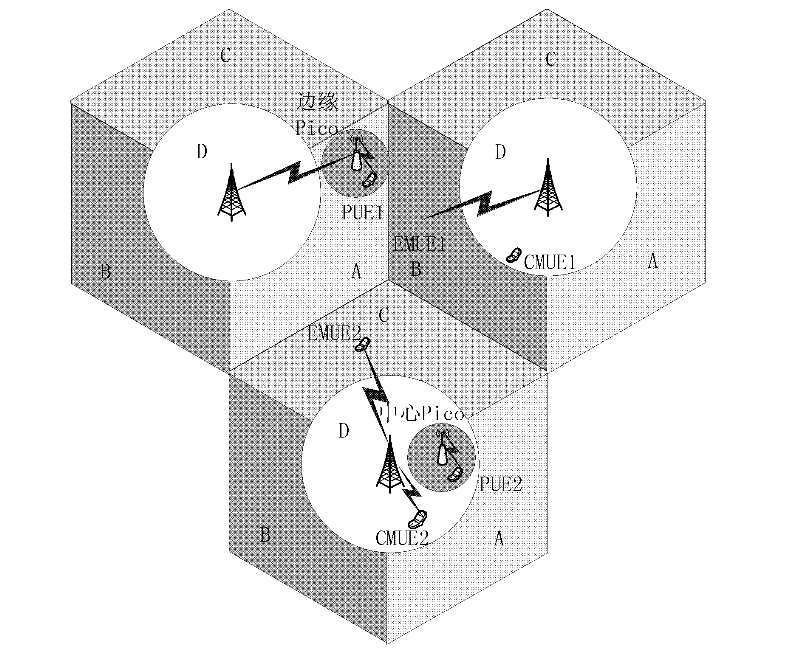

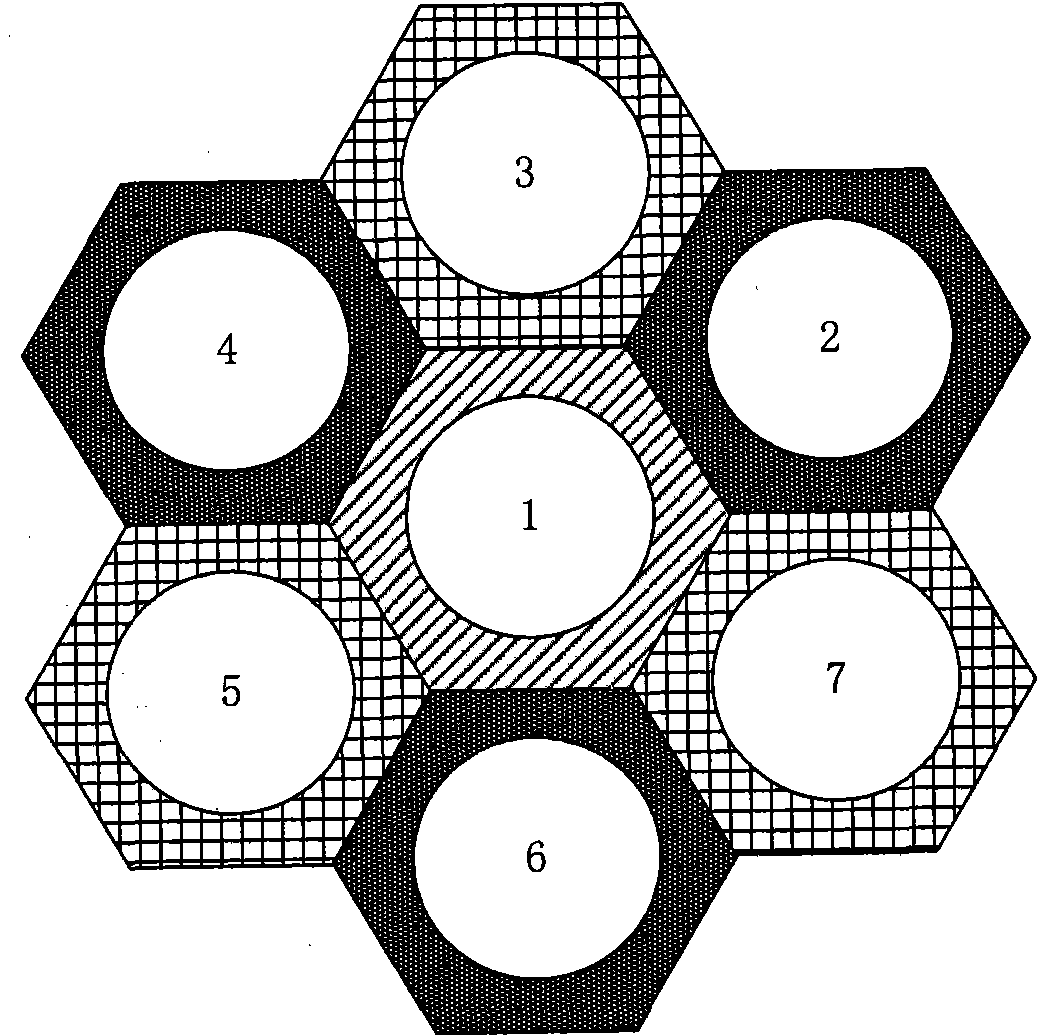

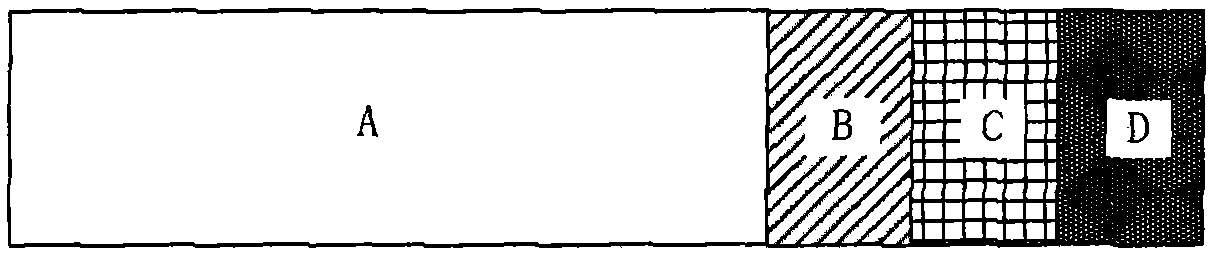

Dynamic spectrum sharing (DSS) method used in multi-cell heterogeneous network (Het-Net)

InactiveCN102378185ANo need to change the layoutImprove communication qualityNetwork planningFrequency spectrumFrequency reuse

The invention discloses a dynamic spectrum sharing (DSS) method used in a multi-cell heterogeneous network (Het-Net), and belongs to the field of wireless communications. The method comprises the following steps of: dividing each Macro cell into four parts such as one Macro cell inner ring and three Macro cell outer rings, wherein, the three Macro cell outer rings can only use a designated frequency band part, and the Macro cell inner ring can use the frequency bands which are not used by all the Macro cell outer rings; reclassifying Pico cells, wherein, central Pico cells can reuse all uplink frequency bands of the Macro cells only by a TDD (Time Division Duplexing) mode, and edge Pico cells can reuse all the uplink frequency bands of the Macro cells or a downlink frequency band corresponding to an area D by the TDD mode; and averagely allocating available resource in each sector to each CMUE (central Macro user (UE)), EMUE (Edge Macro UE) and PUE (Pico UE) in the sector. The DSS method used in the multi-cell Het-Net has the beneficial effects of obviously improving the communication quality of cell-edge UEs (CEUs), solving the difficulty in a frequency reuse mode between the Macro cells and the Pico cells to a certain extent, and realizing coordination of interference between the Macro cells and the Pico cells.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for extracting sodium p-toluenesulfonate from tiamulin synthesis wastewater

ActiveCN104262210AReduce CODRelieve stressOrganic chemistryOrganic compound preparationActivated carbonChemical oxygen demand

The invention relates to a method for extracting sodium p-toluenesulfonate from tiamulin synthesis wastewater, which comprises the following steps: regulating the pH value of tiamulin ammonification production wastewater to 7-8, and concentrating to 75-80% of the original volume under reduced pressure; cooling to 0-4 DEG C, stirring for 1-2 hours while keeping the temperature, and filtering; mixing the filter cake with purified water, adding activated carbon, heating to 80 DEG C, stirring for 30-60 minutes while keeping the temperature, and carrying out hot filtration; and cooling the mother solution to 2-4 DEG C to recrystallize, and filtering to obtain the sodium p-toluenesulfonate. A simple method is utilized to extract and recover the sodium p-toluenesulfonate, thereby changing wastes into valuable substances, increasing the available resources, lowering the wastewater COD (chemical oxygen demand), reducing the wastewater treatment pressure and lowering the wastewater treatment cost; and the method is green and environment-friendly, and has sustainable development meanings for production. The COD of the ammonification wastewater treated by the method is lowered by 50-60%, and the concentration of the sodium p-toluenesulfonate is 310 kg / m<3>.

Owner:宁夏泰瑞制药股份有限公司

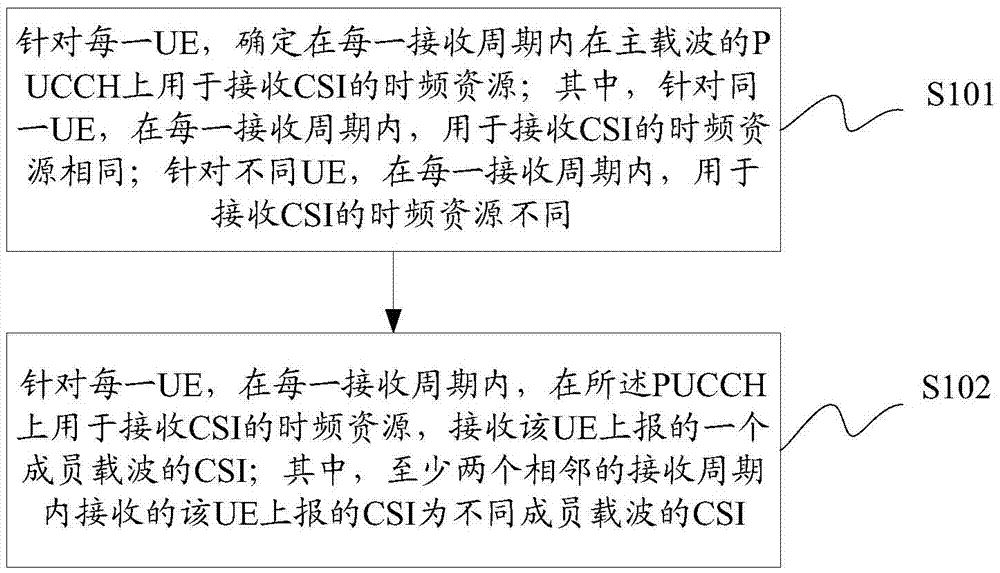

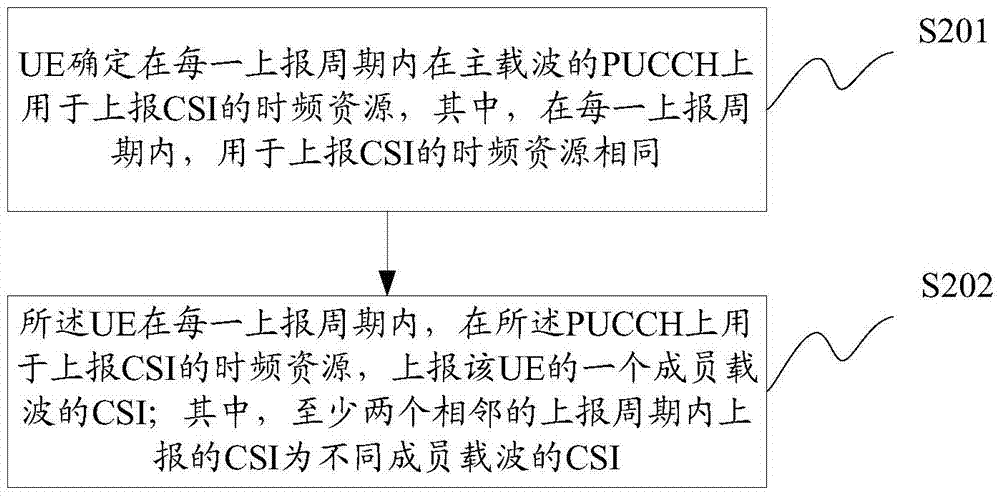

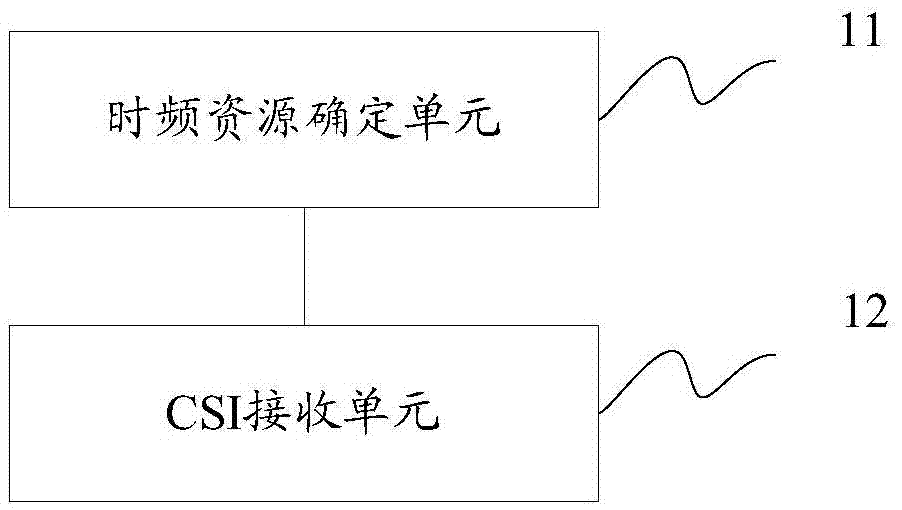

Method and device for receiving CSI (Channel State Information), and method and device for reporting CSI

ActiveCN106998239AReduce occupancyImprove experienceSignalling characterisationError prevention/detection by diversity receptionChannel state informationCarrier signal

The invention discloses a method and a device for receiving CSI (Channel State Information), and a method and a device for reporting the CSI, so as to reduce PUCCH (Physical Uplink Control Channel) resources occupied by the multi-carrier CSI under CA (Carrier Aggregation). The method of receiving the CSI comprises steps: as for each piece of UE, time-frequency resources for receiving the CSI on the PUCCH of a primary carrier are determined, wherein as for the same UE, in each receiving period, the time-frequency resources for receiving the CSI are the same, and as for different UE, in each receiving period, the time-frequency resources for receiving the CSI are different; and as for each piece of UE, in each receiving period, the time-frequency resources for receiving the CSI on the PUCCH receive the CSI of a member carrier reported by the UE, wherein the CSI reported by the UE received in at least two adjacent receiving periods is CSI of different member carriers.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Method for recovering acetylisovaleryltylosin tartrate from acetylisovaleryltylosin tartrate crystallization mother liquor

ActiveCN104693255ASolve the unit is too lowFix stability issuesSugar derivativesSugar derivatives preparationWastewaterSewage

The invention relates to a method for recovering acetylisovaleryltylosin tartrate from an acetylisovaleryltylosin tartrate crystallization mother liquor. The method comprises the following steps: firstly, adding a surfactant into the acetylisovaleryltylosin tartrate crystallization mother liquor, then concentrating a thin film by generating air bubbles, collecting air bubble films, cooling the collected air bubble films, adding a separating agent, separating, filtering, crystallizing the obtained filtrate, and washing with water to obtain pure acetylisovaleryltylosin tartrate. The acetylisovaleryltylosin tartrate is recovered by adopting a simple method, so that the problems that the acetylisovaleryltylosin tartrate crystallization mother liquor is too low in unit content of acetylisovaleryltylosin tartrate and acetylisovaleryltylosin tartrate is poor in thermal stability and can not be recovered can be solved, the recycling of acetylisovaleryltylosin tartrate can be realized, the available resources can be increased, the cost can be lowered, the recovery rate of the finished product can be enhanced, the content of pollutants in discharged wastewater can be reduced, the pollution to environment can be alleviated, and certain social and economical benefits can be achieved.

Owner:宁夏泰瑞制药股份有限公司

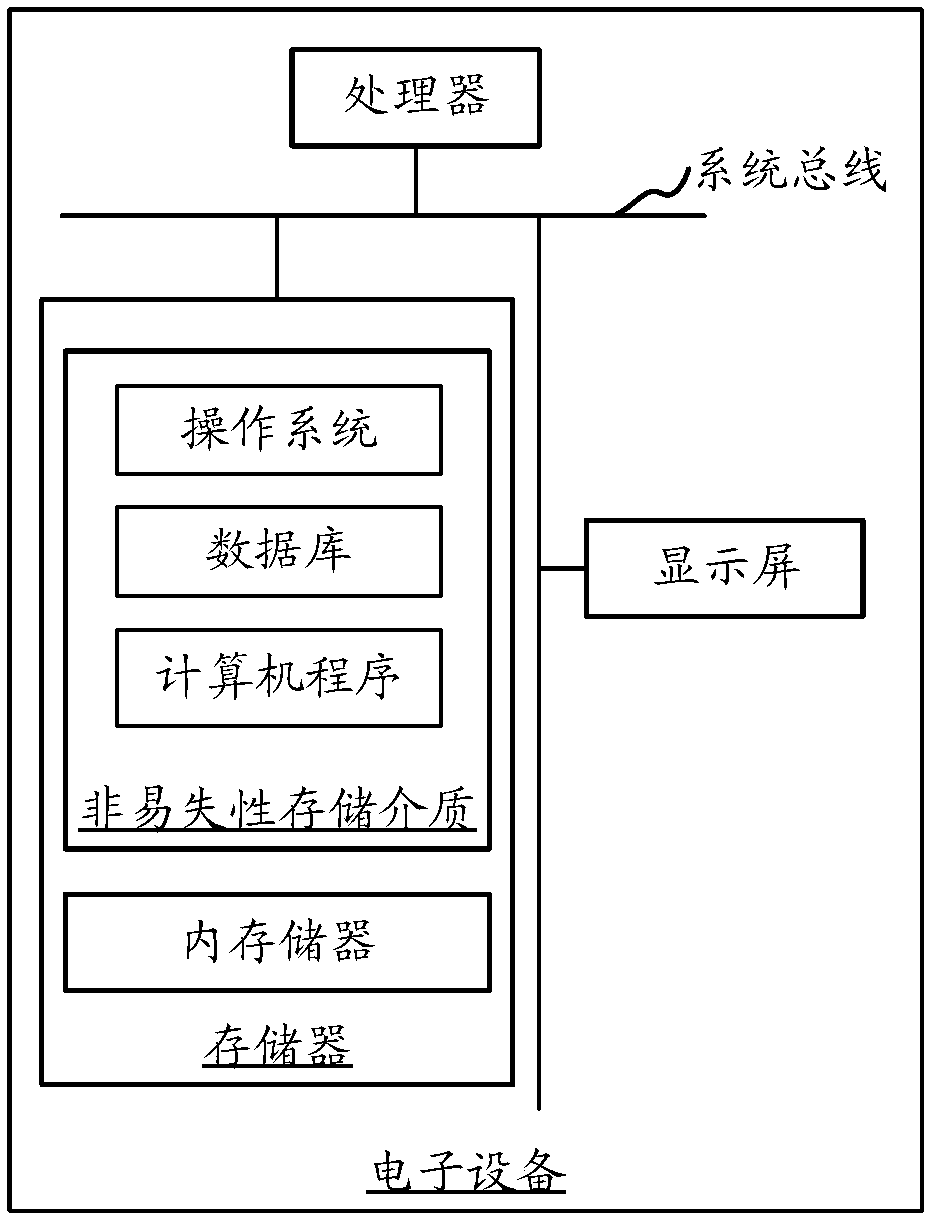

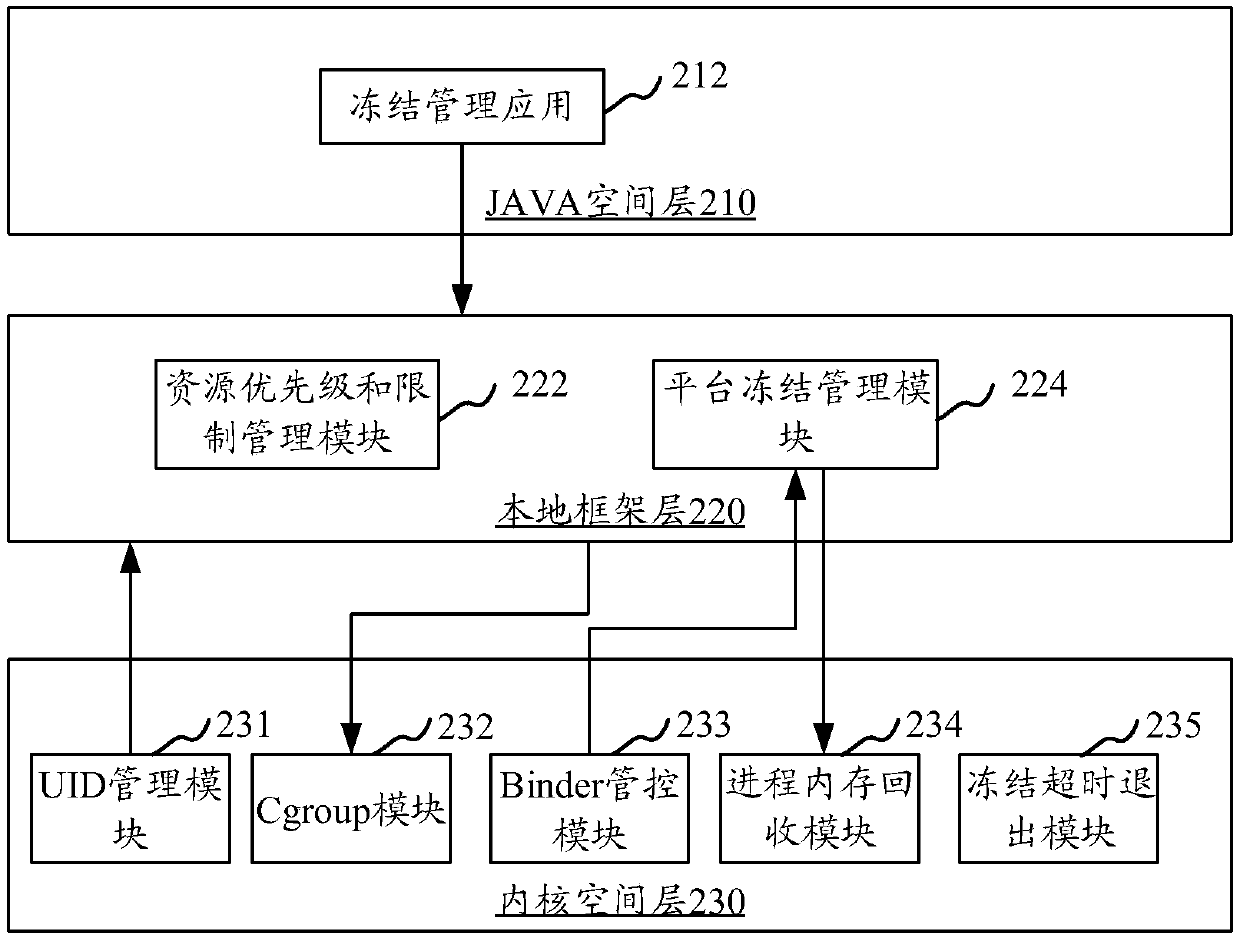

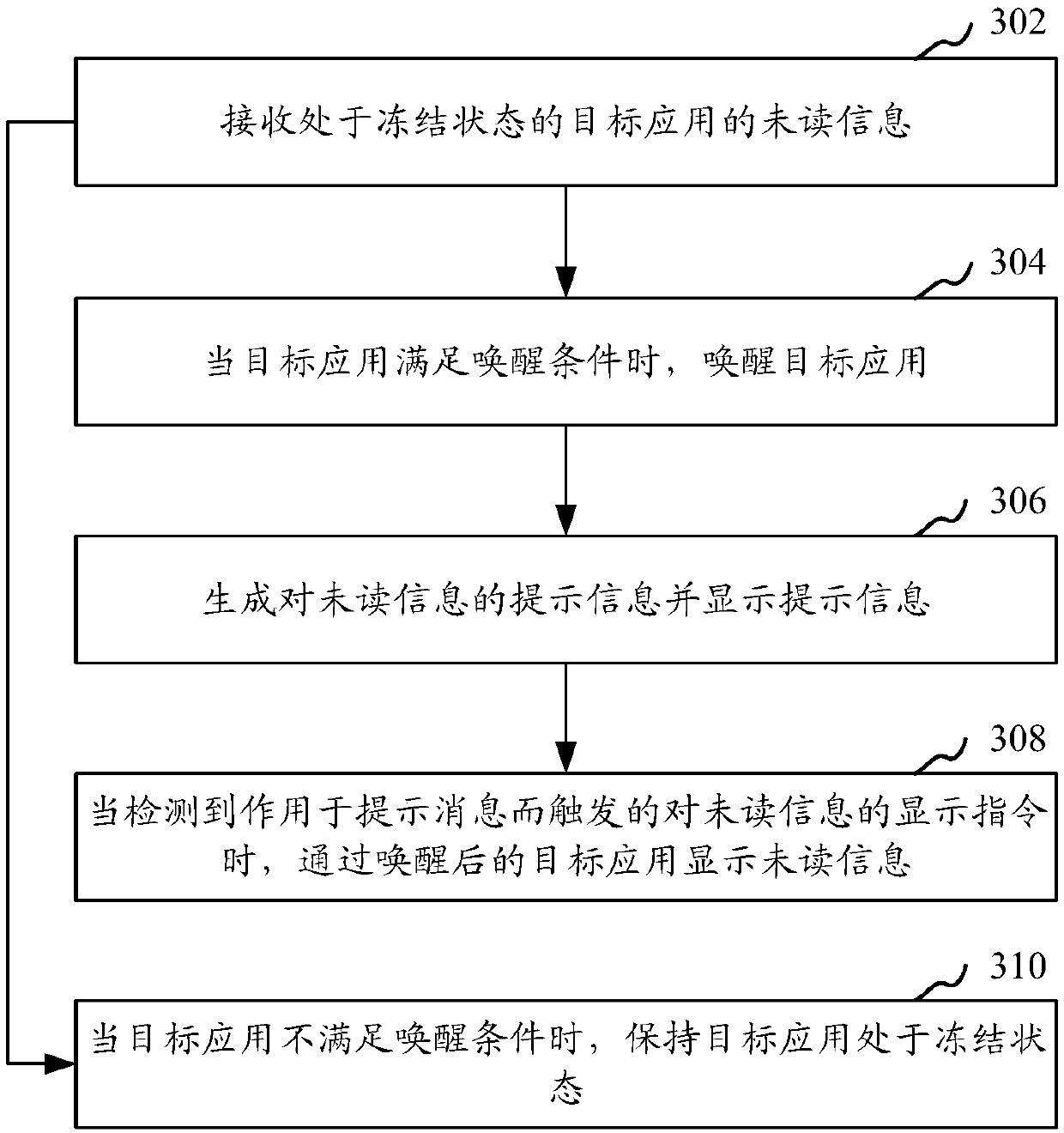

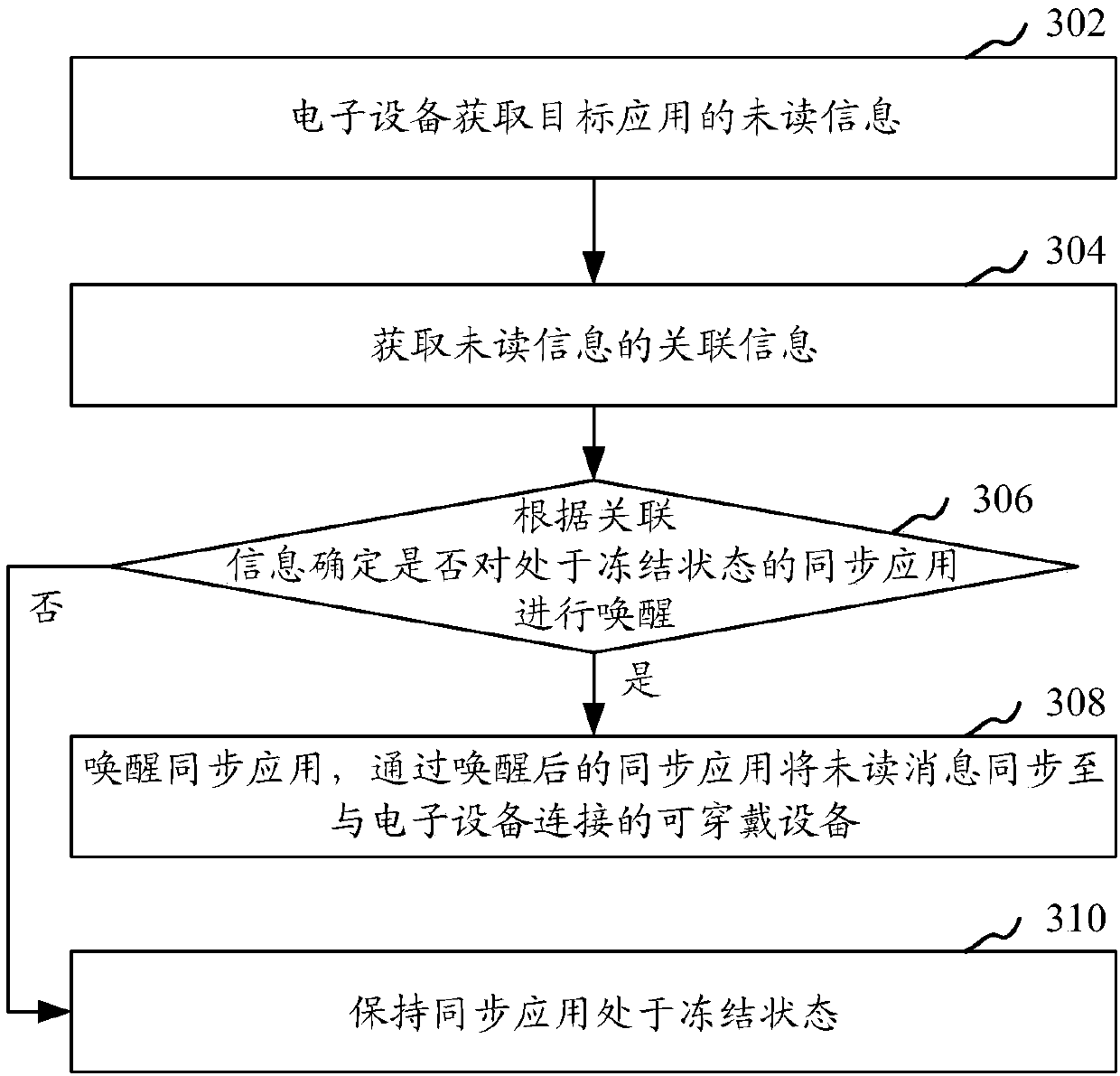

Application processing method and device, electronic equipment and computer readable storage medium

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

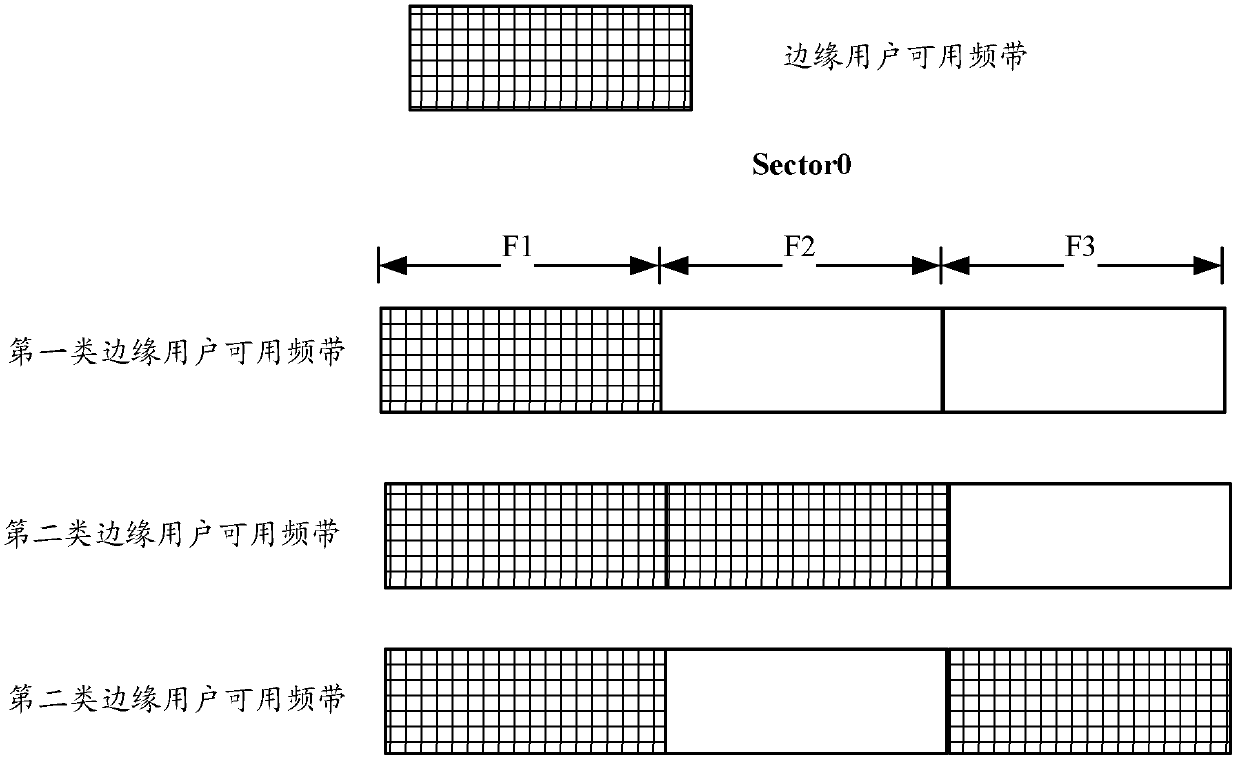

Method for adjustment of user residing sub-band in wireless communication system

InactiveCN103379646AReduce switching timesIncrease available resourcesWireless communicationCommunications systemSwitching cycle

The invention discloses a method for adjustment of a user residing sub-band in a wireless communication system. When a sub-band switching period comes, the steps are taken which includes a step A of adding first edge users residing in a user disabled sub-band in different cells to a first edge user list, selecting a target switching sub-band, a substitutive user and a target switching sub-band thereof for each user to be switched in the list, and adding each user and target switching sub-band information thereof to a switching sub-band information list; a step B of adding second edge users residing in the user disabled sub-band in different cells to a second edge user list, selecting a target switching sub-band, a substitutive user and a target switching sub-band thereof for each user to be switched in the list, and adding each user and target switching sub-band information thereof to the switching sub-band information list; and a step C of carrying out sub-band switching for all users in the switching sub-band information list sequentially according to the adding sequence of the users into the list. According to the invention, resources available to edge users can be increased, sub-band switching frequency of users is reduced, and performance of interference coordination is further improved.

Owner:POTEVIO INFORMATION TECH CO LTD

Turnover blackboard

InactiveCN106394075AIncrease available resourcesWriting boardsFurniture partsWindow shutterEngineering

Owner:芜湖能盟信息技术有限公司

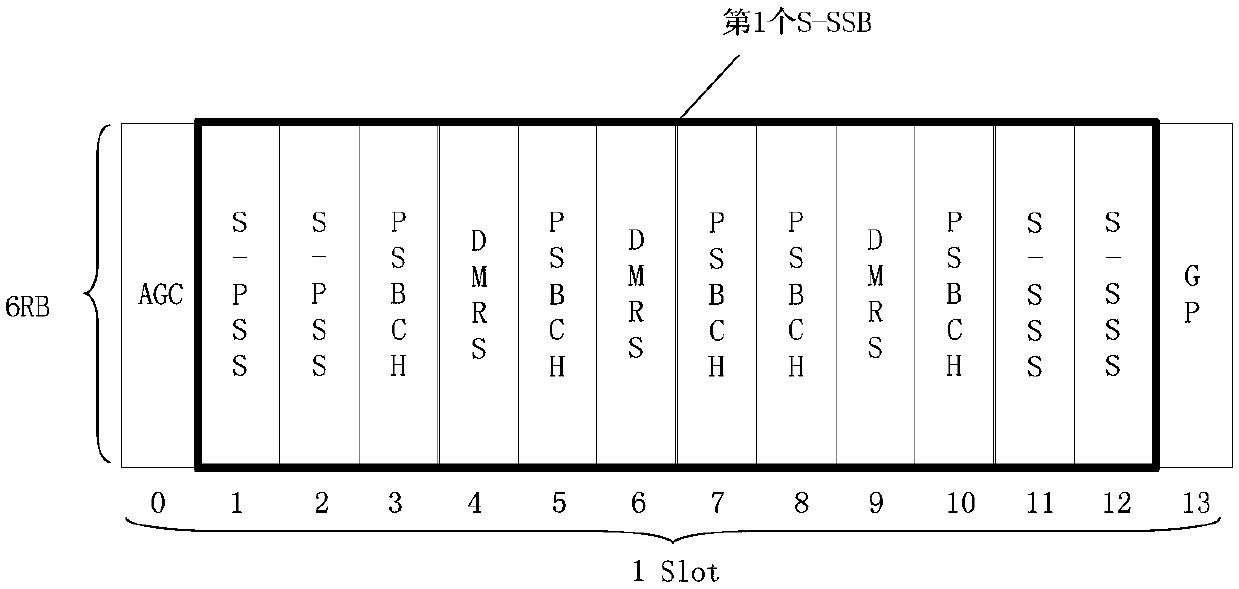

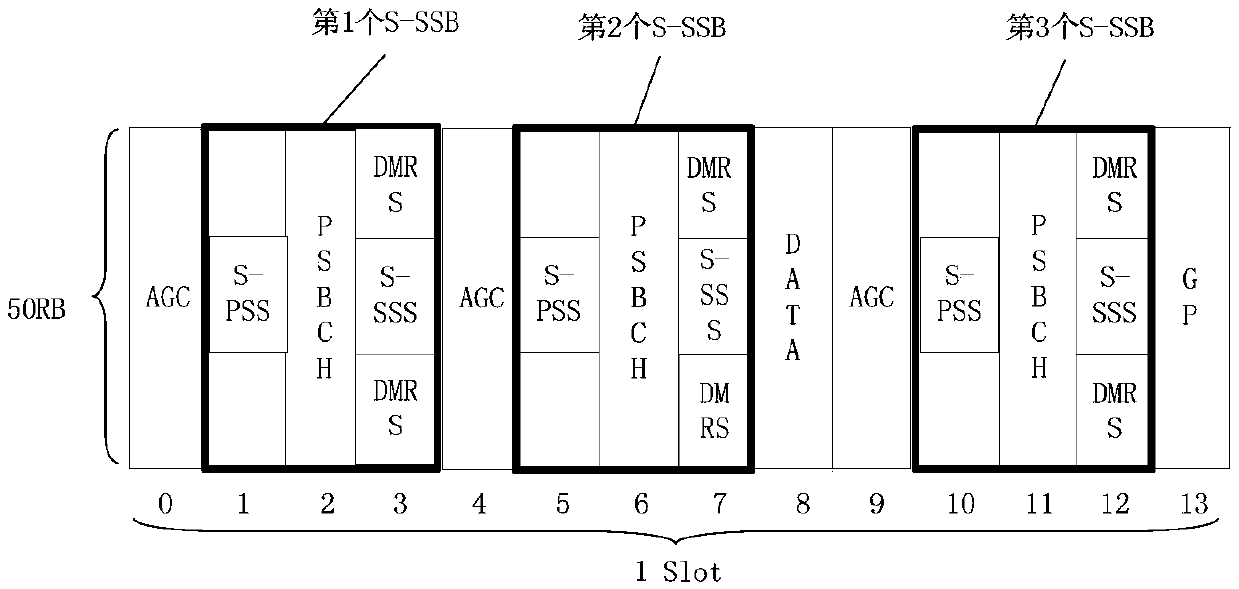

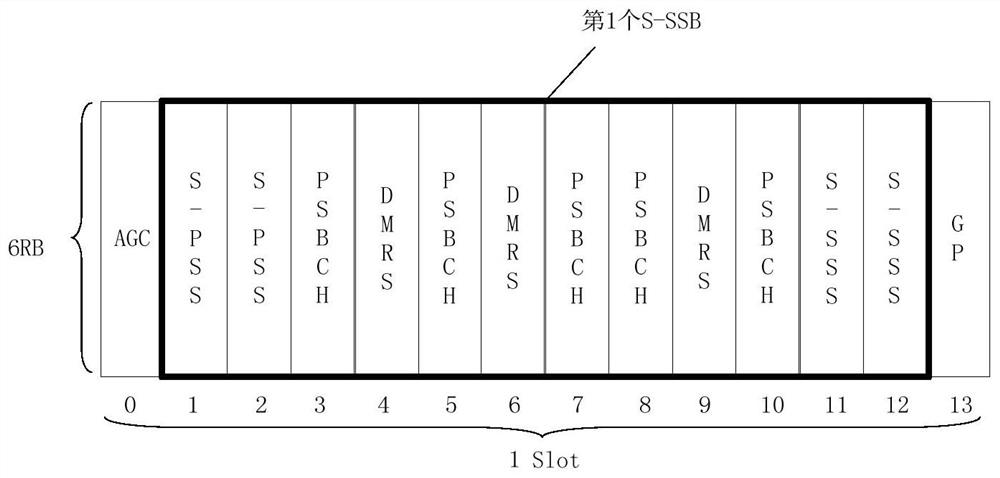

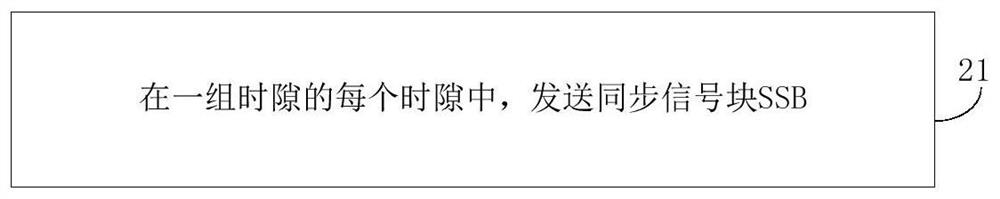

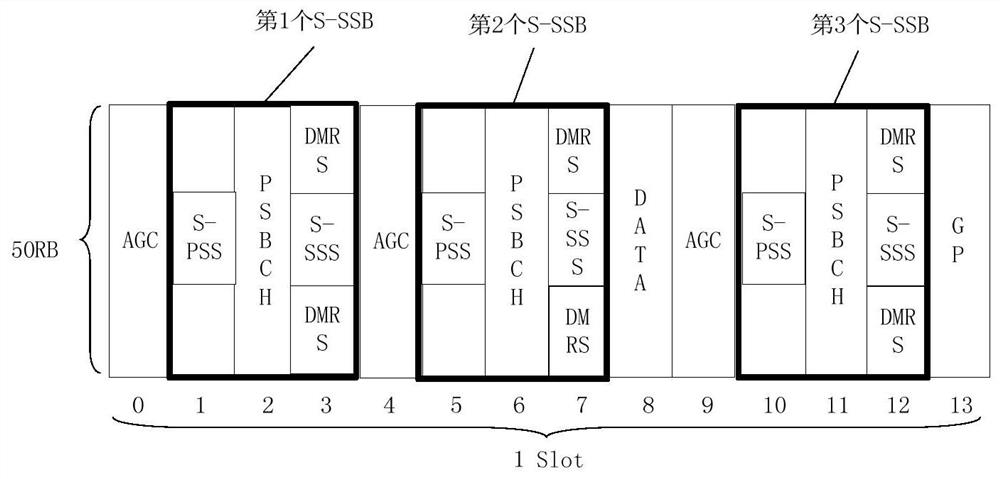

Signal sending method and terminal

ActiveCN111147213AReduce time spentReduce latencyTransmission path divisionPilot signal allocationFrequency-division multiplexingBeam scanning

The invention discloses a signal sending method and a terminal, and the signal sending method comprises the steps: synchronization signal block SSBs are sent in each time slot of a group of time slots, wherein each time slot comprises at least two SSBs; a secondary synchronization signal SSS and a demodulation reference signal DMRS in each SSB are subjected to frequency division multiplexing on atleast one OFDM symbol; and the SSB is a combined block of a primary synchronization signal PSS, the secondary synchronization signal SSS and a physical broadcast channel PBCH. According to the schemeof the invention, more SSBs are accommodated in one Slot, so that the time occupied by beam scanning can be reduced.

Owner:DATANG MOBILE COMM EQUIP CO LTD

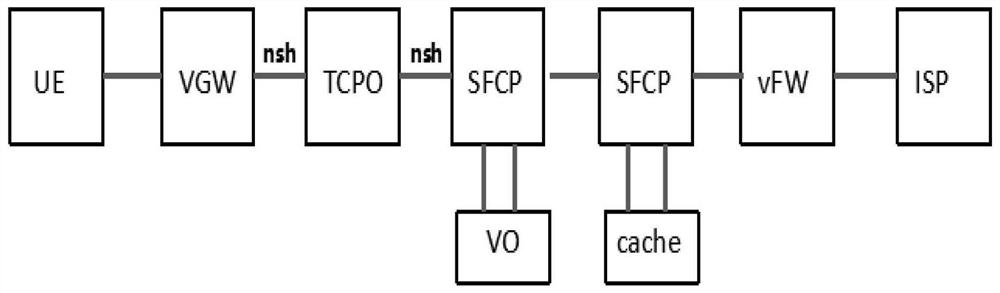

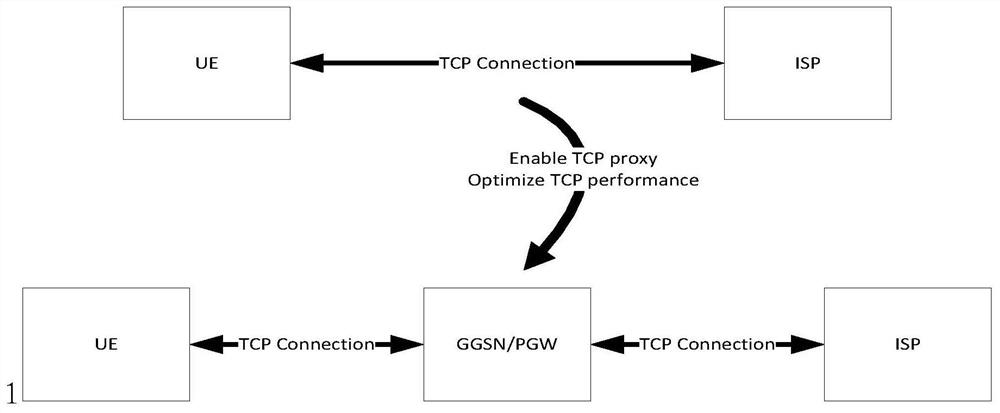

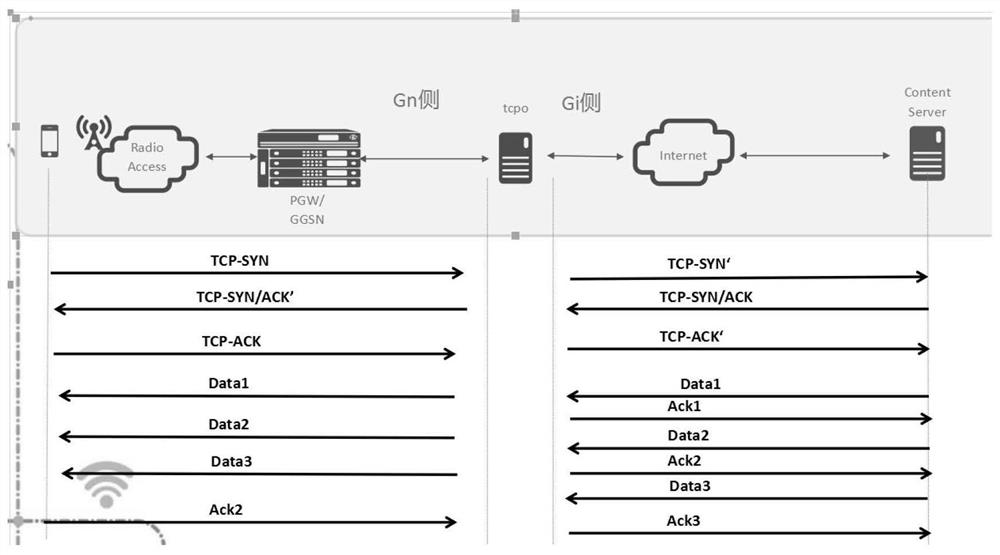

TCP congestion control method and device, terminal and readable storage medium

PendingCN112787942AImprove experienceIncrease available resourcesData switching networksCongestion windowData pack

The invention provides a TCP congestion control method and device, a terminal and a readable storage medium. TheTCP congestion control method comprises the steps of: acquiring ISP resources generated according to a TCP flow request message of a user and sending the ISP resources to a buffer queue by acquiring key features of the user, determining a recommended congestion window of the TCP protocol layer control block is determined according to the key feature, and sending the data packet of the buffer queue to the client according to the principle of a sliding window. The invention further provides a TCP congestion control device, a terminal and a readable storage medium. Corresponding recommended congestion windows are allocated according to respective key features of different users, so that the corresponding recommended congestion windows are provided according to different user pairs instead of the same standard, available resources of effective users are improved, and the user experience is improved.

Owner:ZTE CORP

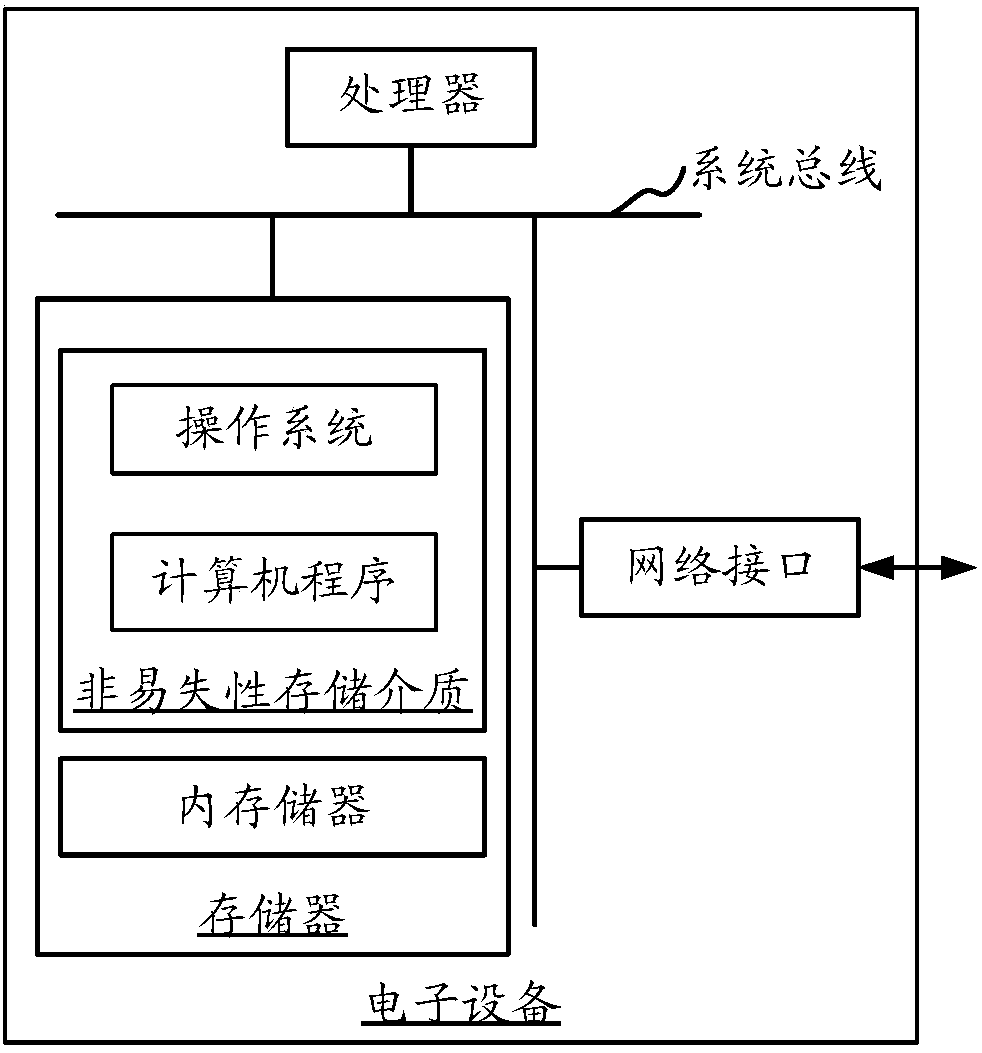

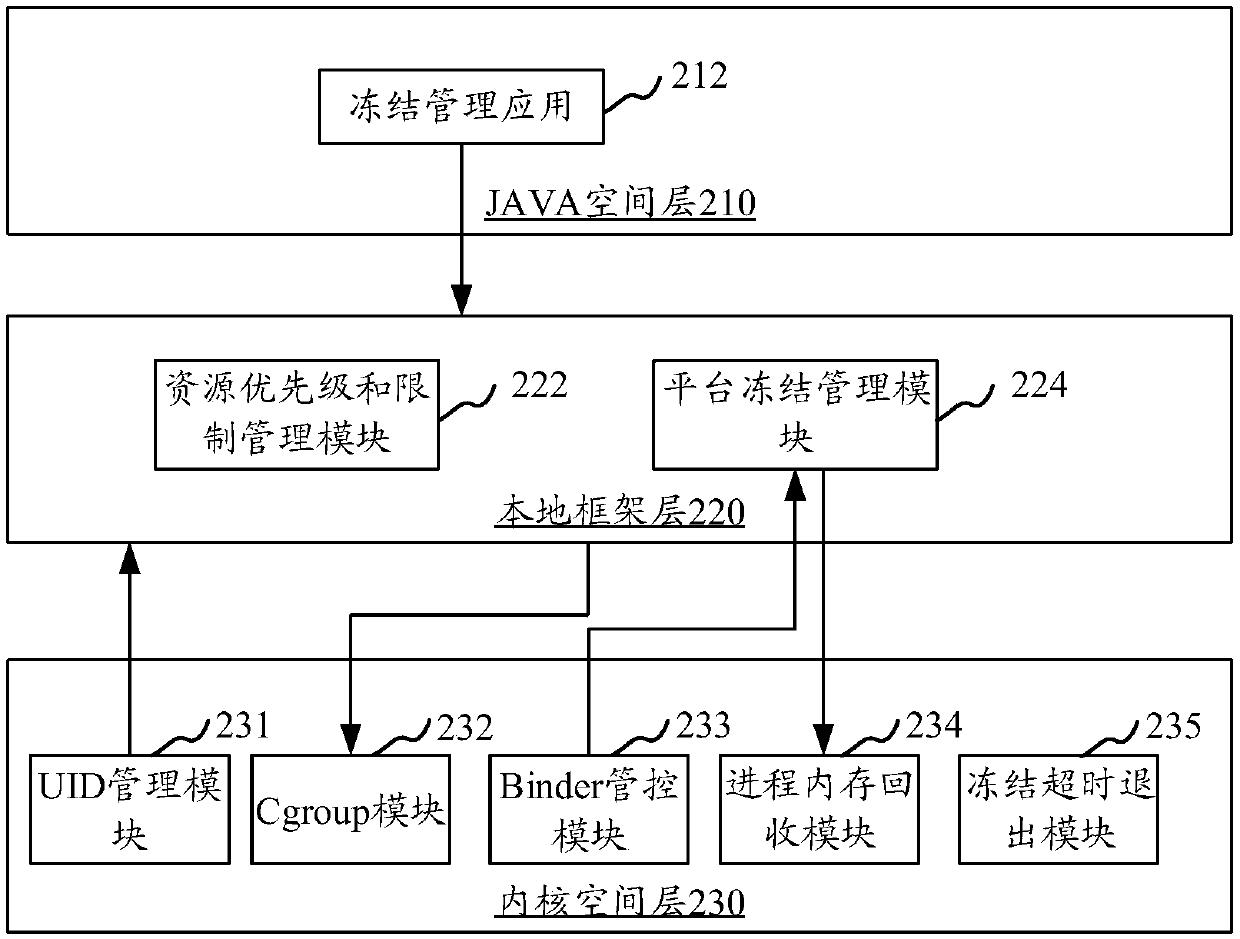

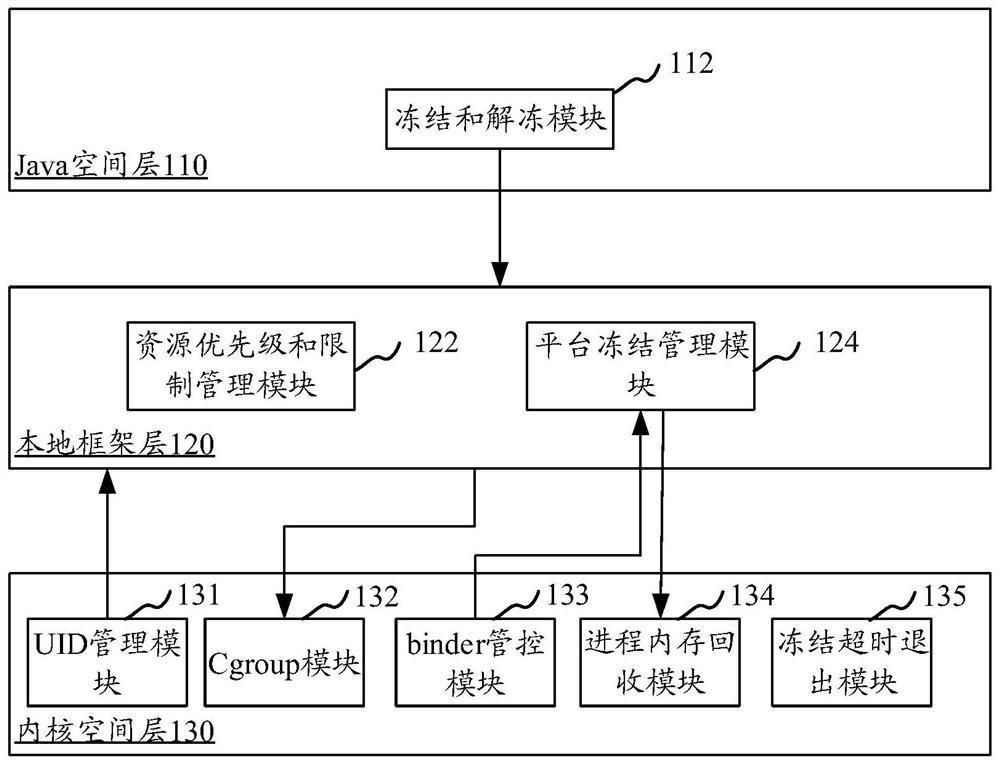

Application processing method and device, electronic equipment and computer readable storage medium

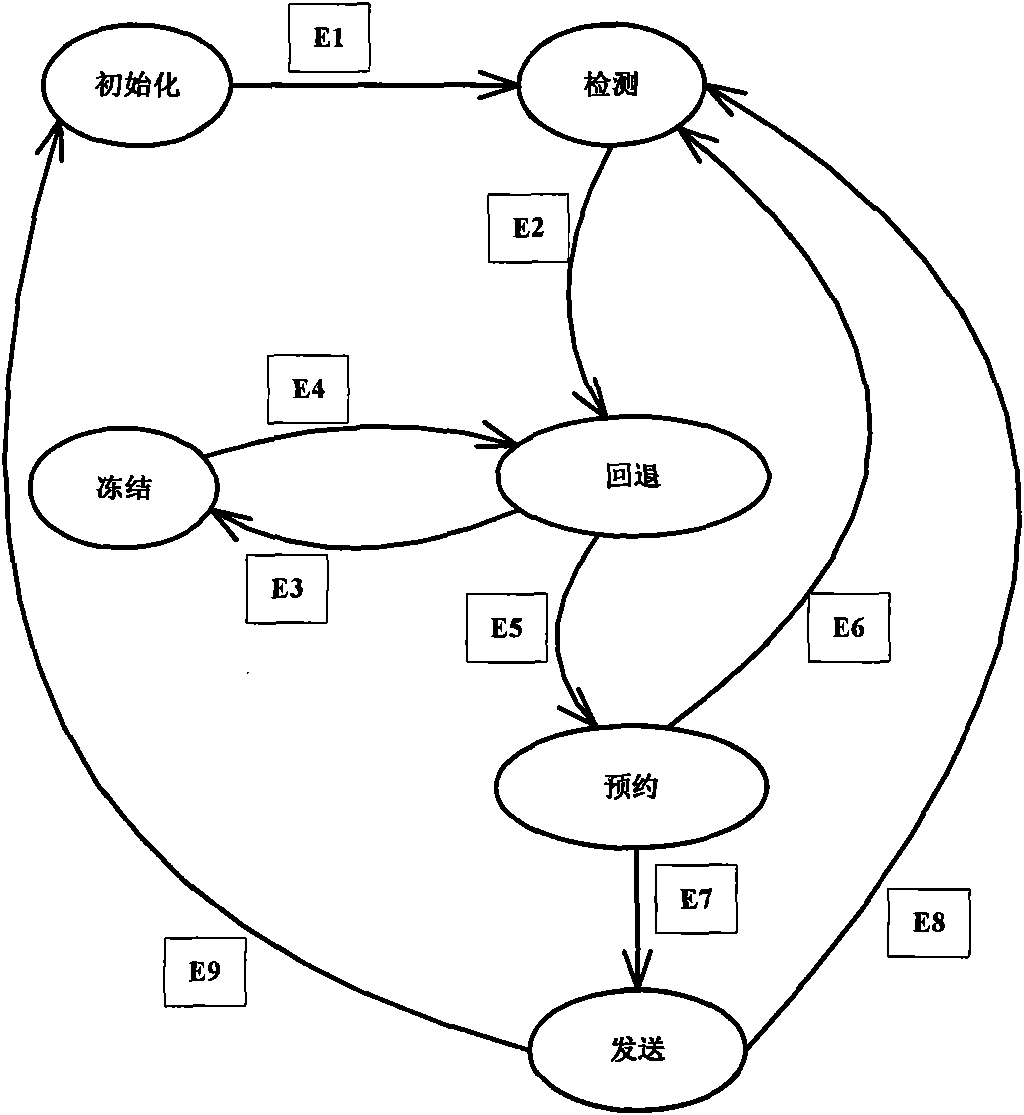

ActiveCN110032398AIncrease available resourcesReduce unnecessary wake-upsProgram initiation/switchingBootstrappingResource utilizationOperating system

The invention relates to an application processing method and device, electronic equipment and a computer readable storage medium. The method comprises the steps that the electronic equipment obtainsunread information of a target application; obtains associated information of the unread information; determines whether to wake up a synchronous application in a frozen state according to the associated information, wherein the synchronous application refers to an application for synchronizing information to the wearable device; if yes, the synchronous application is awakened, and the unread message is synchronized to a wearable device connected with the electronic device through the awakened synchronous application; otherwise, the synchronous application is kept in a frozen state. Through the method, the resource utilization rate of the electronic equipment can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A signal sending method and terminal

ActiveCN111147213BReduce time spentReduce latencyTransmission path divisionPilot signal allocationBeam scanningDemodulation

The invention discloses a signal sending method and a terminal. The signal sending method includes: sending a synchronization signal block SSB in each time slot of a group of time slots; each time slot includes at least two SSBs, each of which The secondary synchronization signal SSS and the demodulation reference signal DMRS in the SSB are frequency division multiplexed on at least one OFDM symbol; the SSB is a combined block of the primary synchronization signal PSS, the secondary synchronization signal SSS and the physical broadcast channel PBCH. The solution of the present invention accommodates more SSBs in one Slot, thereby reducing the time occupied by beam scanning.

Owner:DATANG MOBILE COMM EQUIP CO LTD

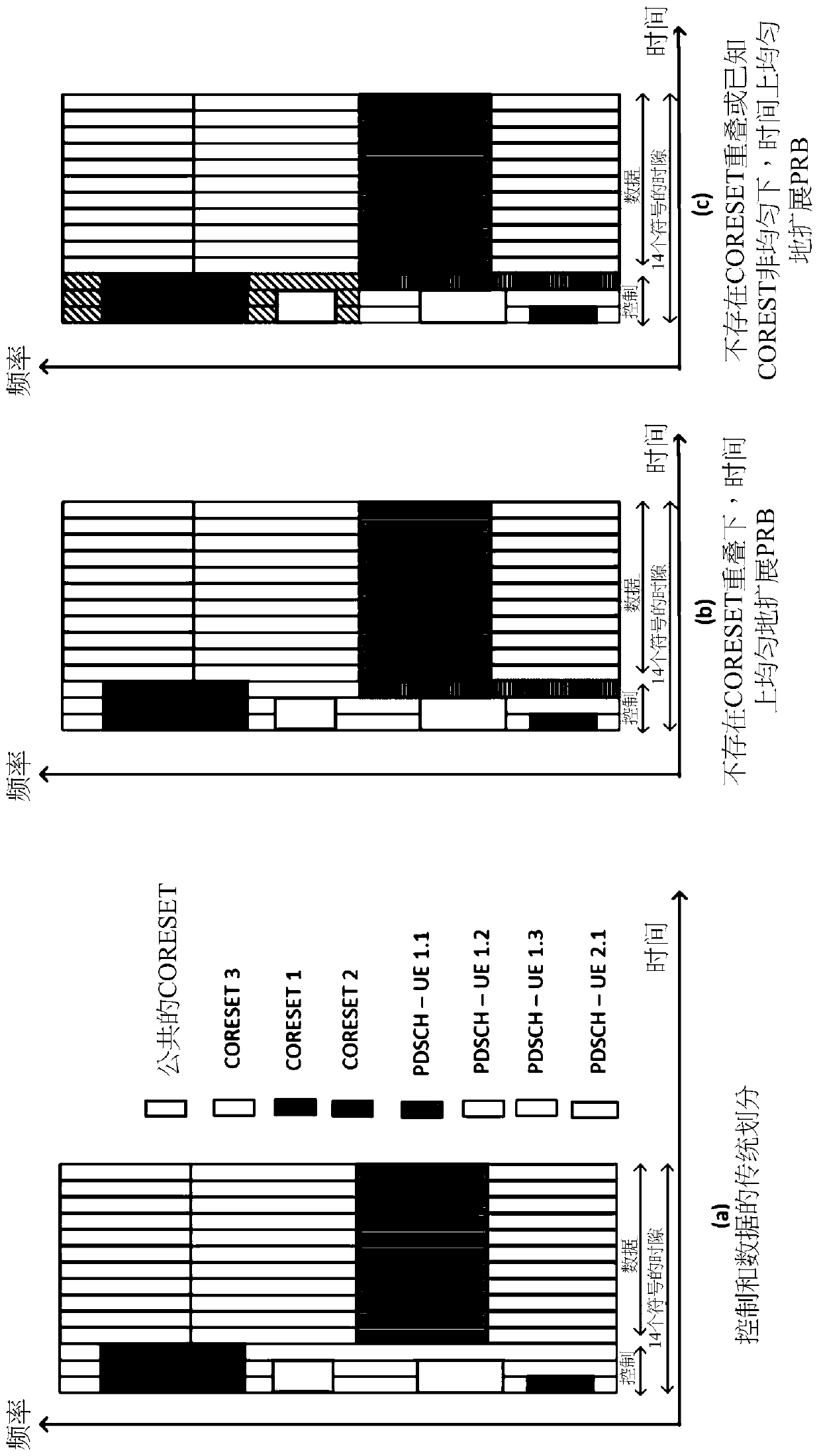

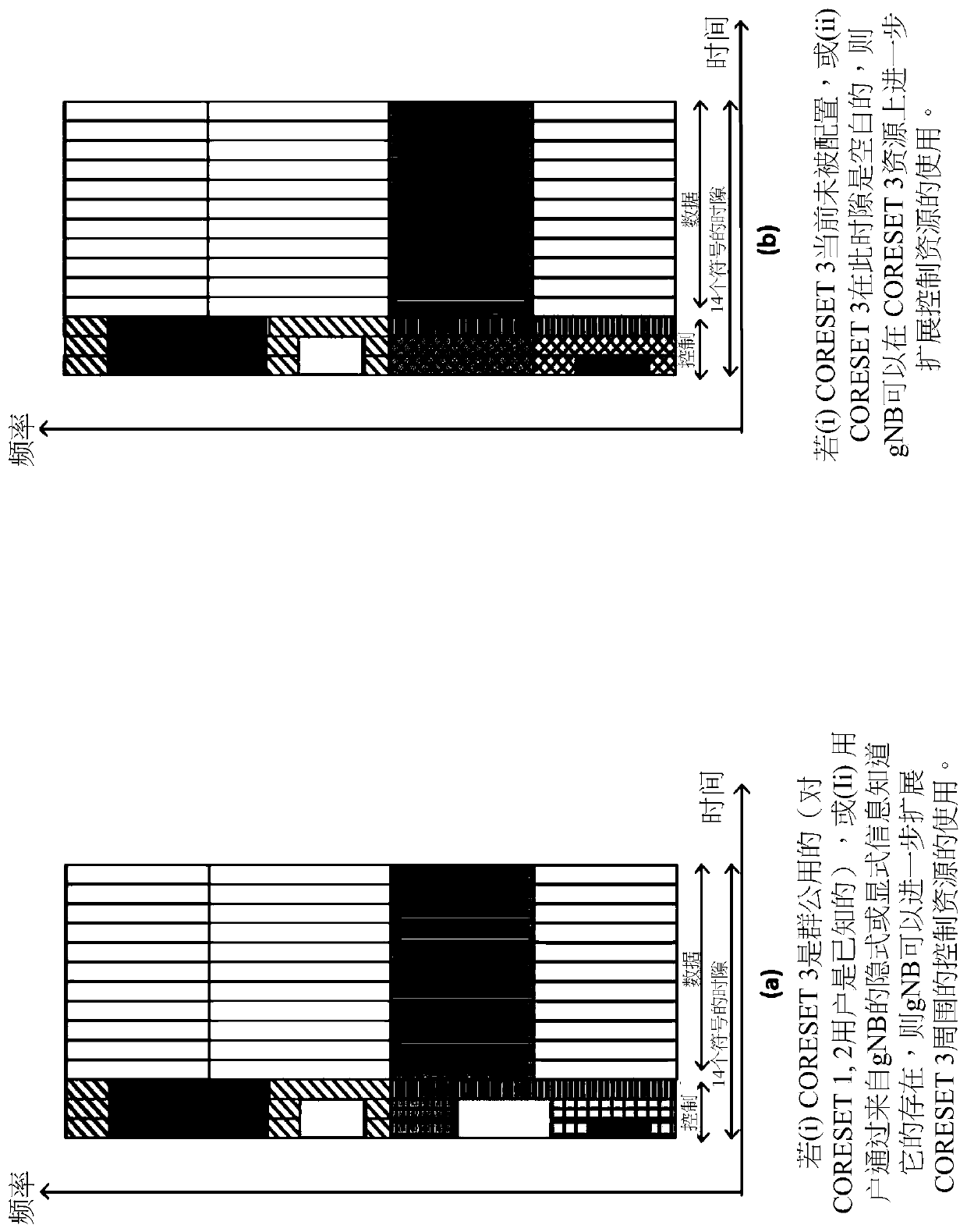

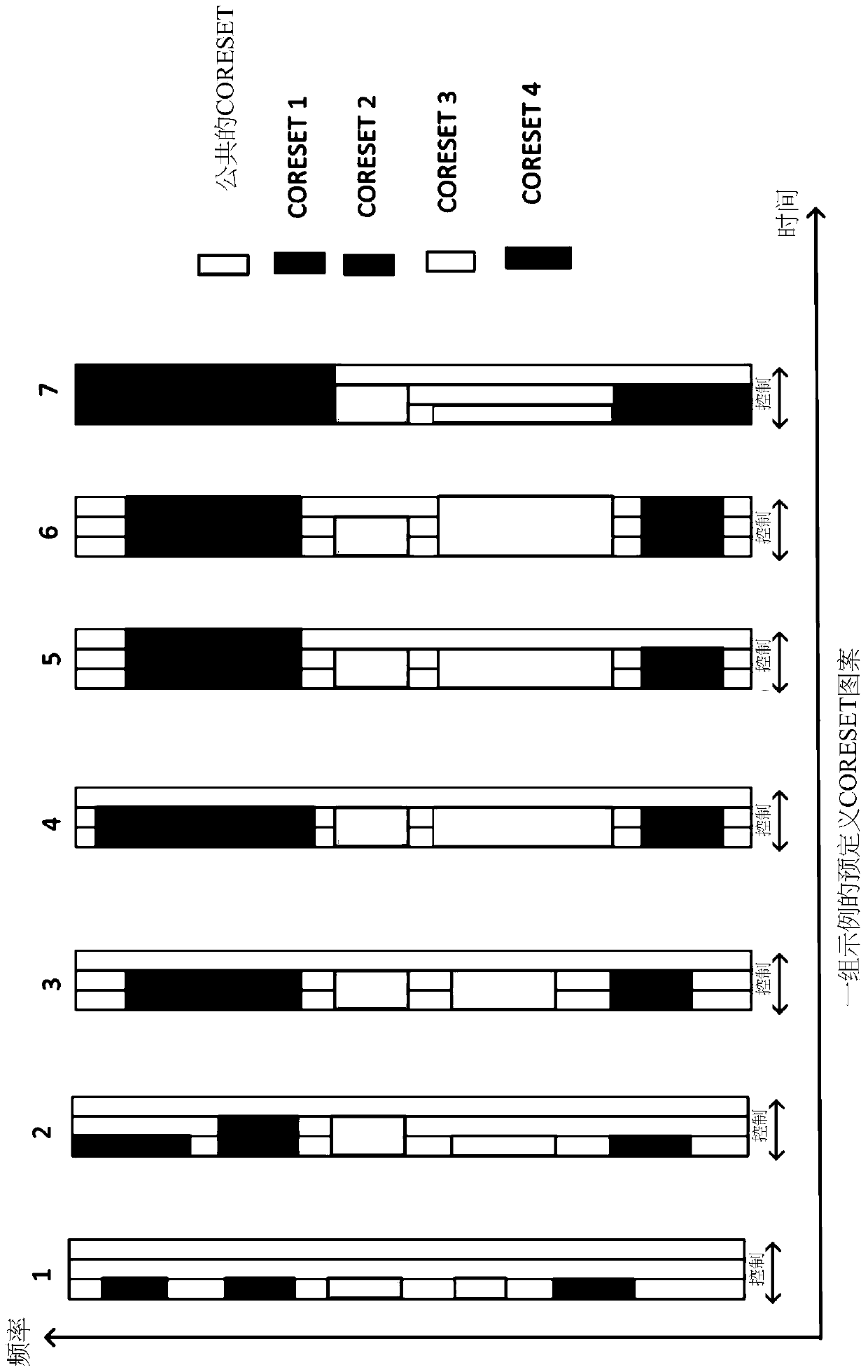

Multiplexing data over control resources in new radio

PendingCN111034299AImprove throughputReduce code rateTransmission path divisionSignal allocationData transmissionEngineering

A method for enabling a wireless communication device to access services provided by a Radio Access Network in a communication between a first and a second wireless communications device, wherein thecommunication includes at least one control region including a group of physical resource blocks, the method comprising: multiplexing data within at least part of the control region to liberate spacein the control region, such that the liberated space can be used for data transmission.

Owner:JRD COMM

A method for extracting sodium p-toluenesulfonate from tiamulin synthetic waste water

ActiveCN104262210BReduce CODRelieve stressOrganic chemistryOrganic compound preparationP-toluenesulfonateWater treatment

The invention relates to a method for extracting sodium p-toluenesulfonate from tiamulin synthesis wastewater, comprising the following steps: adjusting the pH of the tiamulin ammoniation production wastewater to 7-8, and then concentrating under reduced pressure to the original volume 75%~80%; cool down to 0~4°C, keep stirring for 1~2 hours, filter; mix the obtained filter cake with purified water, add activated carbon, heat up to 80°C, keep stirring for 30~60 minutes, then carry out hot filtration; Cool the obtained mother liquor to 2-4°C for recrystallization, and filter again to obtain sodium p-toluenesulfonate. The present invention adopts a relatively simple method to extract and recycle sodium p-toluenesulfonate, turn waste into treasure, increase available resources, and most importantly reduce waste water COD, reduce waste water treatment pressure, and reduce waste water treatment cost. Green and environmentally friendly, it has sustainable development significance for production. The COD of ammoniated wastewater treated by the present invention is reduced by 50% to 60%, and 310kg / m of sodium p-toluenesulfonate is obtained. 3 .

Owner:宁夏泰瑞制药股份有限公司

Soft space frequency multiplexing method and device, base station

ActiveCN102487372BImprove throughputThroughput minimizationError preventionMulti-frequency code systemsMultiplexingResource block

The invention discloses a soft spatial-frequency reuse (SSFR) method and an apparatus thereof, and a base station. The method comprises the following steps that: according to intensity of a pilot signal feedbacked by a user, an area of a cell that the user is located at is determined as well as frequency resources that are available for the user are determined; according to the frequency resources that are available for the user, corresponded transmitting powers are distributed and resource scheduling is carried out; according to a resource scheduling result, group users are selected, wherein the group users include users that use the same physical resource block (PRB) as the user uses in the same cell and a neighboring cell; a minimum interference leakage matrix is obtained according to the group users as well as under the minimum interference leakage matrix, the interference of downlink data of the user on the set user is minimum, wherein the downlink data are sent by a serving base station of the cell that the user is located at; a precoding matrix of the user is obtained according to the minimum interference leakage matrix; and on the basis of the precoding matrix, precoding is carried out on the downlink data so as to obtain precoded data. According to the embodiment of the invention, on the condition that the total throughput of a cell is not reduced, the throughput of a cell edge area (CEA) is increased.

Owner:BEIJING UNIV OF POSTS & TELECOMM

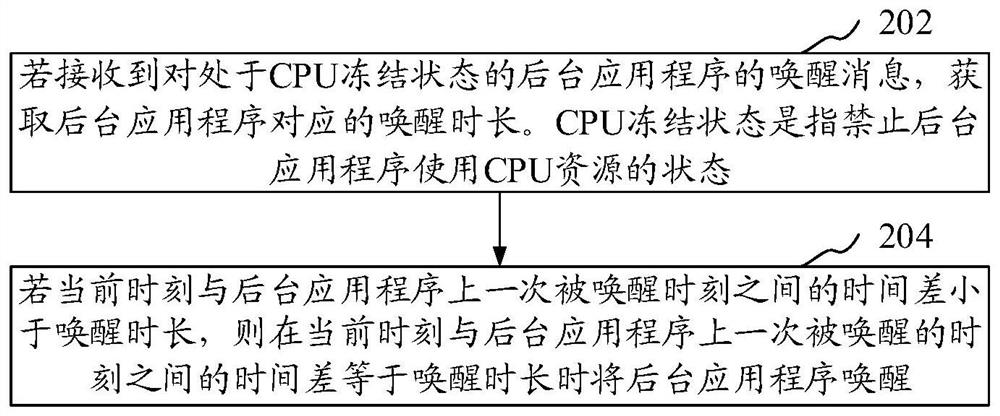

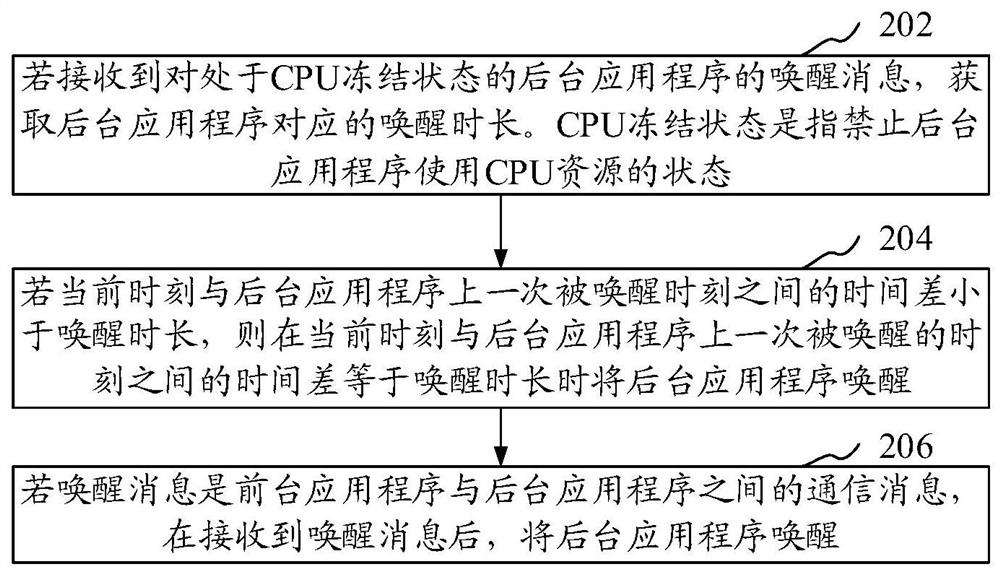

Information processing method, apparatus, computer device, and computer-readable storage medium

ActiveCN109992377BReduce wakeup timesRaise the resource limit rateProgram initiation/switchingResource allocationInformation processingTime difference

The present application provides an information processing method, device, computer equipment, and computer-readable storage medium. The above method includes: if receiving a wake-up message for a background application in a CPU freezing state, obtaining the wake-up duration corresponding to the background application; the CPU freezing state refers to a state in which the background application is prohibited from using CPU resources ; If the time difference between the current moment and the last wake-up time of the background application is less than the wake-up duration, then the time difference between the current moment and the last wake-up time of the background application is equal to the wake-up duration wakes up the background application when. The above method aligns multiple wake-up messages to wake up the background application, reduces the number of times the background application is woken up, and improves the resource limit rate of the computer device to the background application, so as to save power consumption of the computer device and improve the availability of the foreground application. resource.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Method for mapping dynamically inside and outside network of server based on DDNS and NAT

InactiveCN101043447BFacilitate communicationImprove resource utilizationNetwork connectionsDomain nameIp address

Owner:CHONGQING UNIV +1

Time frequency two-dimensional hybrid MAC layer access method

InactiveCN102076106BIncrease chance of random accessIncrease available resourcesWireless communicationTime domainAccess method

The invention discloses a time frequency two-dimensional hybrid media access control (MAC) layer access method. In the two-dimensional direction of a frequency domain and a time domain, multiple users can compete with an available resource together, wherein the available resource comprises each sub channel and different time slots. Conflict is avoided by adopting a withdrawal mechanism, and the users are accessed to a wireless channel to transmit data by competing with the available resource and combining a reservation mechanism. The frequency resource and the time resource are simultaneously utilized in the method, and the competition and the reservation mechanism are combined, so that the utilization rate of the system channel is improved; and the conflict is avoided, so that the throughput of the whole system is effectively improved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Method, device and system for frequency resource sharing

InactiveCN102404750BIncreased frequency sharing efficiencyAvoid interferenceNetwork planningFrequency sharingThroughput

Owner:李春秀

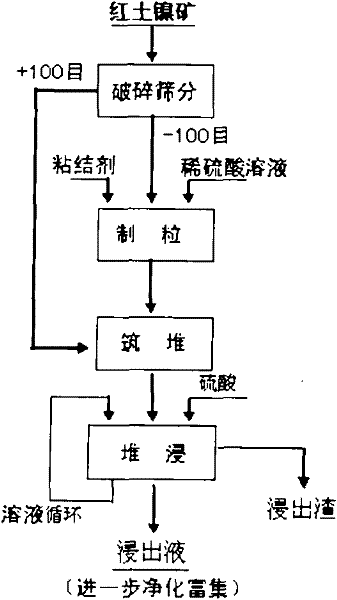

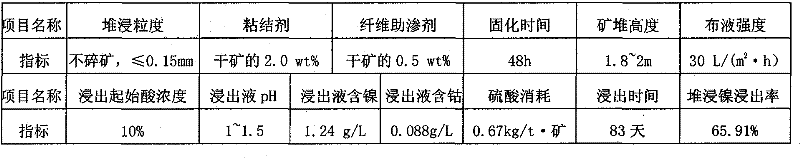

Method for extracting nickel and cobalt through granulating and heap-leaching laterite nickel ore

InactiveCN101717864BReduce investmentIncrease available resourcesProcess efficiency improvementGranularityAcid concentration

The invention provides a method for extracting nickel and cobalt through granulating and heap-leaching laterite nickel ores. The method comprises the following steps of: firstly, breaking and screening raw ores to granulate until the ore is made into 100-mesh; secondly, granulating and curing: adding a binder and sulfuric acid solution according to a certain proportion to granulate in a disc granulator, wherein the compound binder is a mixture of sodium humate and water glass, the adding amount is 1-5% of the amount of core, the concentration of sulfuric acid is 5-10% so that the water content of the aggregate reaches 10-16%, and the granularity of the aggregate is 5-20mm; and in order to ensure that the aggregate has proper wet strength, the prepared aggregate is cured before heaping; thirdly, constructing heaps, and fourthly, spraying: spraying circularly or dropwise according to 3-20% of acid concentration and 5-80L / m<2>.h of spraying strength; and when the concentration of a nickel ion in lixivium reaches 1-3g / L and iron ion reaches 10-30g / L, taking out the acid to obtain the lixivium containing nickel and cobalt. The invention has simple and convenient technique, short process, small investment, low energy consumption, favorable ore-penetration and higher nickel and cobalt leaching efficiencies.

Owner:有研资源环境技术研究院(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com