Method for extracting nickel and cobalt through granulating and heap-leaching laterite nickel ore

A lateritic nickel ore and heap leaching technology, applied in the direction of improving process efficiency, etc., can solve the problems of ore heap knotting, high mud content, affecting the infiltration rate of ore heap and oxygen ventilation, etc., and achieve the effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

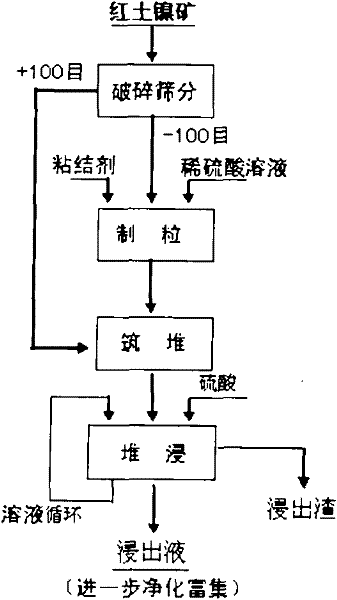

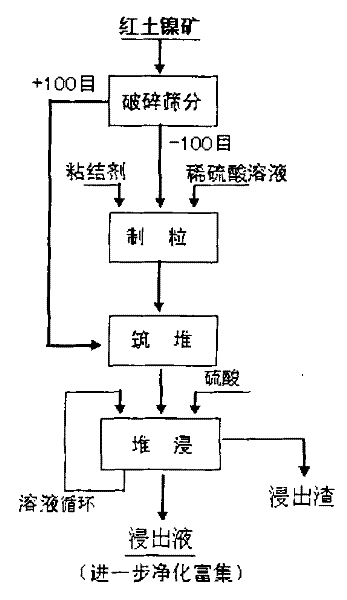

Method used

Image

Examples

Embodiment 1

[0036] The chemical composition of laterite nickel ore is shown in Table 1:

[0037] Table 1 Results of multi-element chemical analysis of laterite nickel ore

[0038] sample name

[0039] The process conditions and main technical indicators of lateritic nickel ore granulation heap leaching are shown in Table 2.

[0040] Table 2 Process conditions and main technical indicators of heap leaching of lateritic nickel ore granulation 1

[0041] project name

[0042] Note*: The binder is a mixture of sodium humate and water glass, and the ratio of the two is 1:5 to 1:10% (weight ratio). Same below

Embodiment 2

[0044] The chemical composition of laterite nickel ore is identical with embodiment 1.

[0045] The process conditions and main technical indicators of lateritic nickel ore granulation heap leaching are shown in Table 3.

[0046] Table 3 Process conditions and main technical indicators of heap leaching of lateritic nickel ore granulation 2

[0047] project name

Embodiment 3

[0049] The chemical composition of laterite nickel ore is identical with embodiment 1. The difference is that a fiber penetration aid is added during granulation, and the fiber penetration aid is a plastic braided belt or the like.

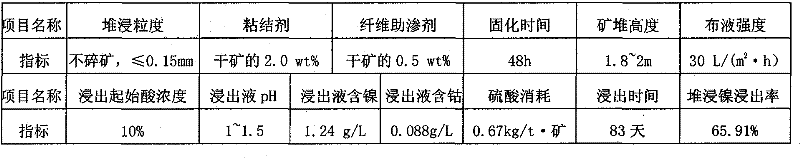

[0050] The process conditions and main technical indicators of lateritic nickel ore granulation heap leaching are shown in Table 4.

[0051] Table 4 Process conditions and main technical indicators of lateritic nickel ore granulation heap leaching 3

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com